Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu roller guides

The Importance of Roller Guides in Modern Machinery

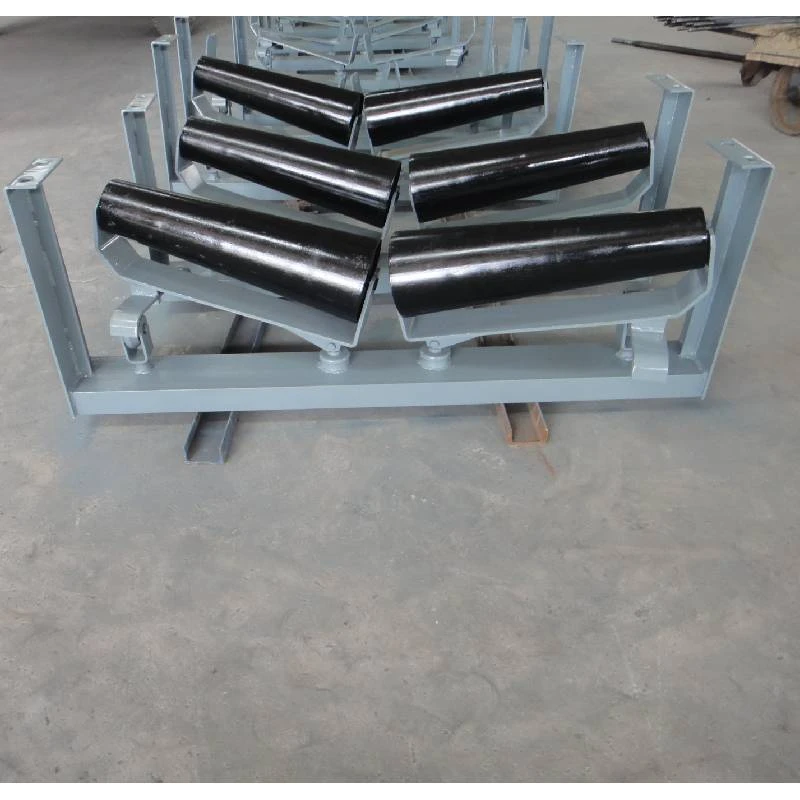

Roller guides are critical components in various industrial applications, serving as a vital mechanism for ensuring smooth and efficient operation of machinery. These guides are designed to reduce friction, enhance the performance of moving parts, and prolong the lifespan of equipment. Understanding the functionality, types, and benefits of roller guides can help industries optimize their operations and maintain high standards of productivity.

What Are Roller Guides?

Roller guides consist of rollers placed between two surfaces, allowing for easy movement and stability. These components are commonly used in conveyor systems, linear motion assemblies, and various types of machinery where heavy loads are involved. The primary function of roller guides is to facilitate the movement of components along a predetermined path while minimizing contact friction. This results in increased efficiency and reduced wear and tear on both the guides and the machinery.

Types of Roller Guides

There are several types of roller guides, each designed for specific applications and environments. The most common types include

1. Linear Roller Guides These are used in applications requiring precise linear motion. They often feature a steel or plastic casing that houses multiple rollers, providing smooth and accurate movement along a rail or track.

2. Tapered Roller Guides These are designed to bear heavy loads and accommodate angular loads. Their tapered shape allows for effective load distribution, making them ideal for applications such as automotive wheel bearings.

3. Ball Roller Guides A combination of rollers and balls, these guides offer low-friction movement suitable for lightweight applications. They are often used in furniture or small machinery where minimal resistance is desired.

4. Heavy-Duty Roller Guides These are engineered to withstand substantial loads and harsh environments, making them suitable for industrial and construction applications.

roller guides

5. Custom Roller Guides Many manufacturers offer bespoke solutions tailored to specific machinery requirements. These guides can be designed to fit unique applications, accommodating various weights, speeds, and environmental conditions.

Benefits of Using Roller Guides

The implementation of roller guides in machinery offers numerous advantages

1. Reduced Friction By minimizing contact between moving parts, roller guides significantly reduce friction, leading to less energy consumption and improved efficiency.

2. Increased Precision Roller guides enhance the accuracy of movements in machinery, which is particularly important in applications requiring high precision, such as CNC machines and robotics.

3. Extended Equipment Lifespan The reduction in mechanical wear caused by friction translates into a longer lifespan for both roller guides and the machinery they support, resulting in lower maintenance costs.

4. Versatility With various designs available, roller guides can be used in a diverse range of applications across multiple industries, from manufacturing to transportation.

5. Ease of Installation and Maintenance Most roller guides are designed for straightforward installation and require minimal maintenance, making them a cost-effective solution for improving machinery performance.

Conclusion

Roller guides are indispensable components in the machinery of today’s industrial landscape. Their ability to efficiently manage movement, reduce friction, and extend the longevity of equipment makes them a smart choice for a wide range of applications. As technology continues to advance, the design and capabilities of roller guides will likely evolve, offering even greater benefits in terms of efficiency and performance. For businesses looking to enhance their operational efficiency, investing in high-quality roller guides is a strategic move that can yield significant returns.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025