Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

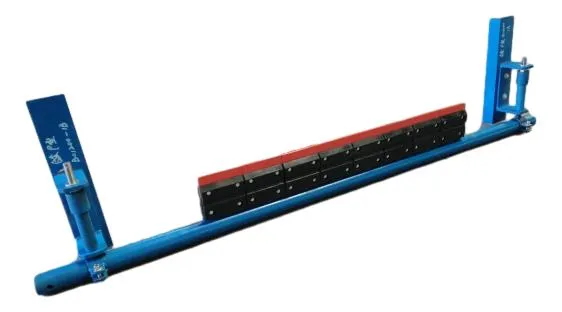

Zulu roller conveyor parts

Understanding Roller Conveyor Parts A Comprehensive Guide

Roller conveyors are fundamental components in the material handling and logistics sectors, serving a variety of industries, from manufacturing and warehousing to shipping and distribution. These conveyor systems enable the efficient movement of goods and products, minimizing manual labor and reducing the risk of injury associated with heavy lifting. To fully appreciate the advantages of roller conveyors, it is essential to understand the various parts that make up these systems and their respective functions.

1. Frame

The frame is the backbone of a roller conveyor. It provides the necessary structural support and stability to the entire system. Typically made from durable materials like steel or aluminum, the frame is designed to withstand heavy loads and endure rigorous operations. Depending on the application, frames can be configured in various designs, such as straight, curved, or inclined, to meet specific handling needs.

2. Rollers

The rollers are the most critical components of the conveyor. They facilitate the movement of products along the conveyor system. Rollers can be either powered (motor-driven) or non-powered (gravity). Non-powered rollers rely on gravity to move items downhill, while powered rollers have an embedded drive mechanism that can transport materials along a flat or inclined surface. Rollers come in different sizes, materials, and configurations, including straight, tapered, or spiral designs, to accommodate varying types of goods and materials.

In some roller conveyor systems, additional conveyor belts may be integrated to enhance movement efficiency. These belts can assist in moving items that require extra stability or support, especially smaller, lighter products. Conveyor belts are often made from rubber or fabric and can be customized with different surfaces to prevent slippage and ensure reliable operation.

4. Drive Mechanisms

The drive mechanisms provide the necessary power to move the rollers. These can include electric motors, gear reducers, and chains or belts that transmit power from the motor to the rollers. Different drive configurations, such as a centralized drive or a distributed drive (where each roller has its own motor), can be employed based on the application requirements. Proper maintenance of these drive mechanisms is crucial to ensure the longevity and efficiency of the conveyor system.

roller conveyor parts

5. Idlers

Idlers are used to support the conveyor belt in powered systems, helping to maintain tension and alignment during operation. They prevent the belt from sagging and ensure smooth and consistent material flow. Idlers are typically located at various points along the conveyor and come in different shapes and designs based on the conveyor's operational needs.

6. End and Side Stops

To keep products from rolling off the conveyor, end stops and side stops are essential components. End stops prevent items from falling off at the end of the conveyor while side stops ensure products remain securely on the belt during transport. These stops can often be adjustable to accommodate different-sized items and can be easily replaced if damaged.

7. Sensors and Controls

Modern roller conveyors often incorporate sensors and control systems to automate operations. These technologies can manage the speed and direction of the conveyor, detect product presence, and optimize sorting and tracking processes. Sensors can enhance safety by stopping the conveyor in case of obstructions or emergencies.

8. Safety Features

To protect workers and maintain efficiency, roller conveyors are equipped with various safety features. This can include emergency stop buttons, guards to prevent contact with moving parts, and warning lights or alarms to alert personnel of potential hazards.

Conclusion

Roller conveyor systems play an indispensable role in improving operational efficiency across various industries. By understanding the different components of roller conveyors, businesses can make informed decisions about system design, maintenance, and upgrades. Ensuring that all parts are optimized and functioning effectively not only enhances productivity but also contributes to a safer workplace. Properly maintained roller conveyor systems can serve organizations well, supporting their goal of streamlined operations and increased profitability.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025