Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu roller guides

Understanding Roller Guides An Essential Component in Modern Machinery

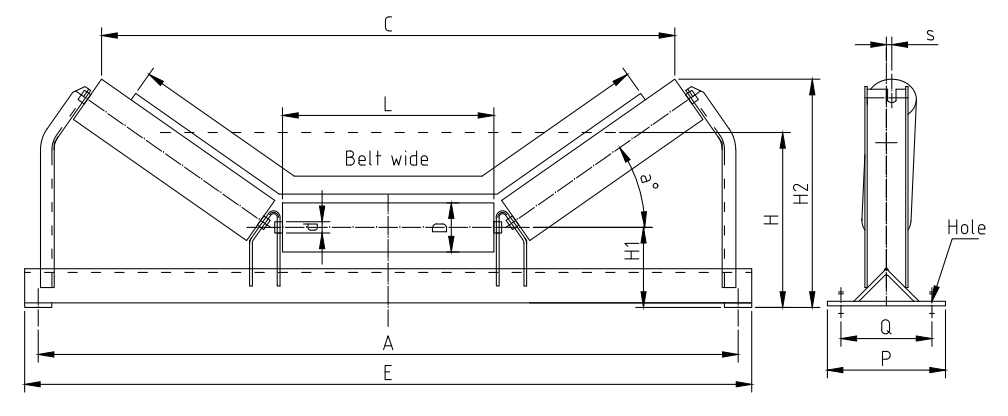

Roller guides are critical components in various mechanical systems, serving to facilitate smooth motion and ensure accurate positioning of moving parts. These guides play a vital role in applications ranging from industrial machinery to transportation systems, enhancing efficiency and reliability in operations.

At its core, a roller guide consists of a series of rollers positioned within a housing, which allows a moving element—such as a rail or a sliding carriage—to glide smoothly along its path. The design of roller guides minimizes friction, which is crucial for reducing wear and tear on machinery components. By decreasing friction, roller guides not only enhance the lifespan of the machinery but also contribute to energy savings, as less force is required to move objects.

One of the primary advantages of roller guides is their ability to support heavy loads while maintaining precise linear motion. This feature makes them indispensable in various industrial applications, such as CNC machines, conveyor systems, and robotic arms. In these contexts, the accuracy of movement is paramount. Roller guides ensure that machinery operates within specified tolerances, thereby maintaining quality control in production processes.

roller guides

Moreover, roller guides come in various designs and configurations, catering to different operational requirements. For instance, some roller guides are designed for high-speed applications, while others are optimized for heavy load capacities. The choice of roller guide will depend on the specific demands of the machinery and the environment in which it operates. Customization options may include varying roller sizes, materials, and arrangements to accommodate unique movement patterns.

Maintenance of roller guides is another crucial aspect that affects their performance and longevity. Regular inspection and lubrication are essential tasks that help prevent malfunctions and prolong the service life of these components. Implementing a proactive maintenance schedule can mitigate unexpected downtimes and optimize operational efficiency.

In recent years, advancements in technology have also led to the development of smart roller guides, which integrate sensors and IoT capabilities. These innovative guides can monitor their own performance in real-time, alerting operators to potential issues before they escalate. This predictive maintenance approach empowers industries to maintain operational continuity and enhance productivity.

In conclusion, roller guides are a cornerstone of efficient machinery operation, providing smooth and precise movement in various applications. Their ability to reduce friction, support heavy loads, and offer customizable solutions marks them as essential tools in modern engineering. As technology evolves, the future of roller guides looks promising, with innovations that further enhance their functionality and efficiency. Understanding and investing in quality roller guides can lead to significant improvements in performance and reliability across numerous industries.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025