Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Understanding the Functionality and Applications of Return Pulleys in Mechanical Systems

Understanding Return Pulleys A Key Component in Mechanical Systems

In the realm of mechanical engineering, system efficiency and functionality often hinge on the design and components employed in machinery. One critical component that plays a pivotal role in various mechanical systems is the return pulley. This article delves into the essence of return pulleys, their applications, and their impact on overall system performance.

A return pulley is a type of pulley that redirects the path of a belt or cable within a mechanical system. It is primarily used in systems where belts, ropes, or cables need to change direction to maintain tension and ensure smooth operation. The significance of return pulleys can be observed in numerous applications, including conveyor belts, elevators, and industrial machinery. Through their design, return pulleys help enhance the operational lifespan of a system by reducing wear and tear on components that come in contact with the belts or cables.

One of the most notable features of return pulleys is their ability to maintain tension in a system. In many mechanical setups, it is crucial to keep a consistent and appropriate tension on the moving elements. This is where the return pulley shines. By redirecting the belt or cable, it allows for the needed tension to be achieved, facilitating optimal performance of the entire system. If the tension is not correctly maintained, it can lead to slippage, increased friction, and ultimately, system failure.

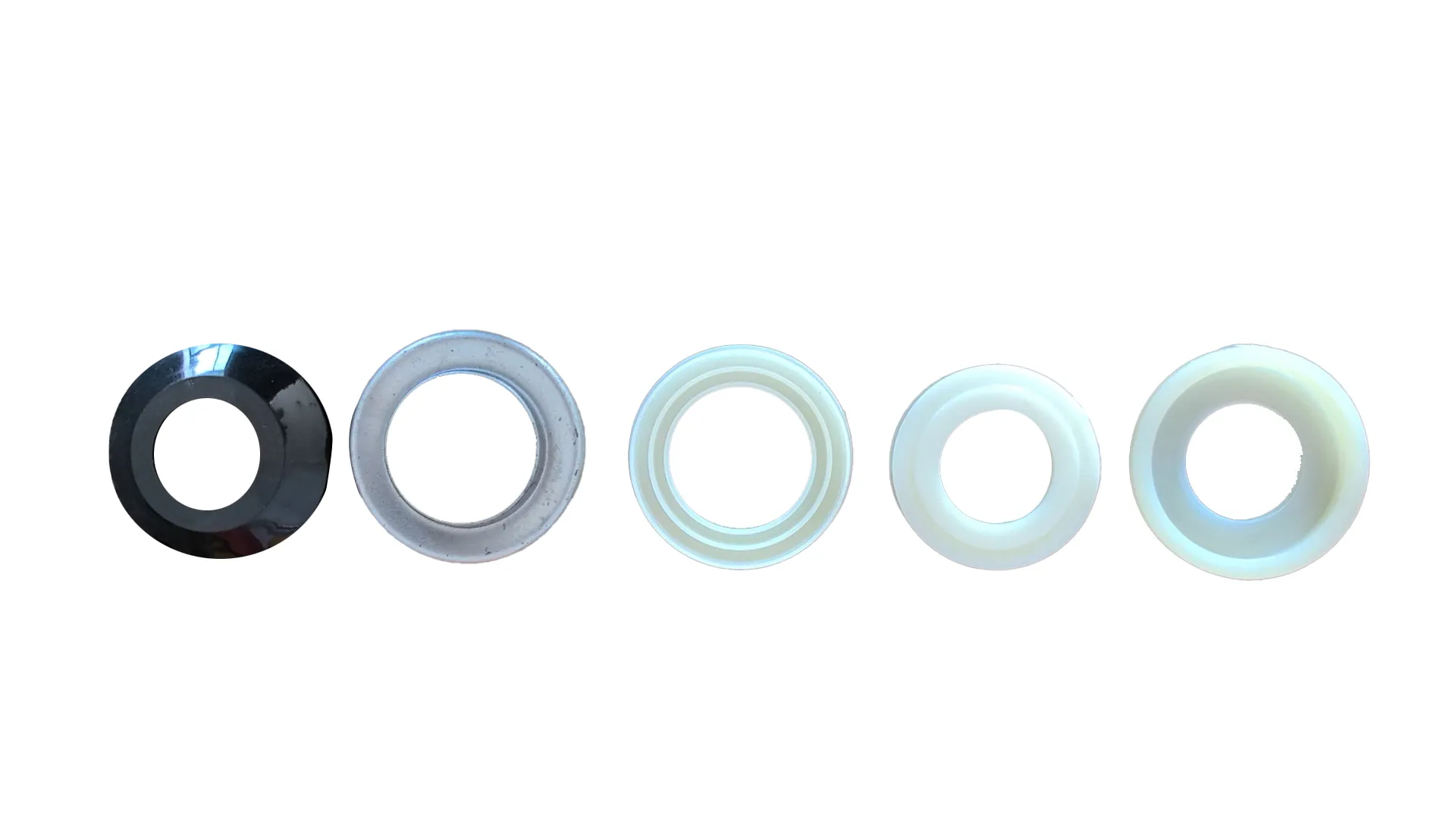

Return pulleys are typically made from materials that offer a combination of strength and durability

. The choice of material is crucial because it needs to withstand the forces exerted by the belt or cable while minimizing wear. Common materials include steel, aluminum, and various composites. A well-designed return pulley should also feature a smooth surface to reduce friction, allowing for efficient movement without unnecessary energy losses.return pulley

The installation of return pulleys can significantly influence the overall design of a mechanical system. Proper placement and alignment are imperative to ensure that the belt or cable is directed accurately. Poor alignment can lead to miscommunication between components, resulting in uneven wear or mechanical failure. Therefore, engineers must carefully consider the geometry and layout of the entire system during the design phase to optimize the placement of return pulleys.

Moreover, return pulleys also contribute to safety in mechanical systems. In cases where a cable or belt may snap or become dislocated, a return pulley can help contain the system's components, preventing potential hazards such as moving parts striking operators or bystanders. This characteristic makes return pulleys not only crucial for performance but also for enhancing the safety of mechanical operations.

The application of return pulleys is widespread across industries. In material handling, return pulleys are integrated into conveyor systems to manage the flow of products efficiently. In the automotive sector, they are used in belt-driven systems to ensure reliable operation of components such as alternators and water pumps. Even in more specialized fields, such as aerospace and robotics, return pulleys play a vital role in ensuring precision and reliability.

In conclusion, return pulleys are an indispensable element in the machinery landscape, providing essential functions like tension management, increased safety, and system efficiency. Their importance spans numerous applications across various industries, underscoring their relevance in modern engineering. As technology progresses, the design and integration of return pulleys are likely to evolve, further enhancing their capabilities and impact in mechanical systems. Understanding and utilizing return pulleys effectively can pave the way for innovations in design, safety, and operational efficiency in mechanical engineering.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025