Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu return pulley

The Importance of Return Pulley Systems in Mechanical Applications

In various mechanical applications, the return pulley plays a crucial role in ensuring the efficient operation of systems involving cables and belts. A return pulley is not just a simple wheel; it is a fundamental component that contributes significantly to the overall functionality of machinery.

At its core, a return pulley serves multiple purposes. Primarily, it redirects the path of a cable or belt, enabling it to change direction while maintaining tension. This is particularly vital in applications such as elevators, conveyor systems, and hoisting equipment. By facilitating the return of the cable or belt to its original position, the return pulley ensures smooth operation and prevents slack, which could lead to mechanical failure or accidents.

Moreover, return pulleys play a vital role in reducing wear and tear on cables and belts

. When cables are subjected to sharp angles or excessive bends, they can suffer from abrasion and eventual breakage. A return pulley alleviates this issue by providing a gentle arc for the cable to follow, thereby extending its lifespan. This not only saves on replacement costs but also enhances safety by minimizing the risk of equipment malfunction due to worn-out components.return pulley

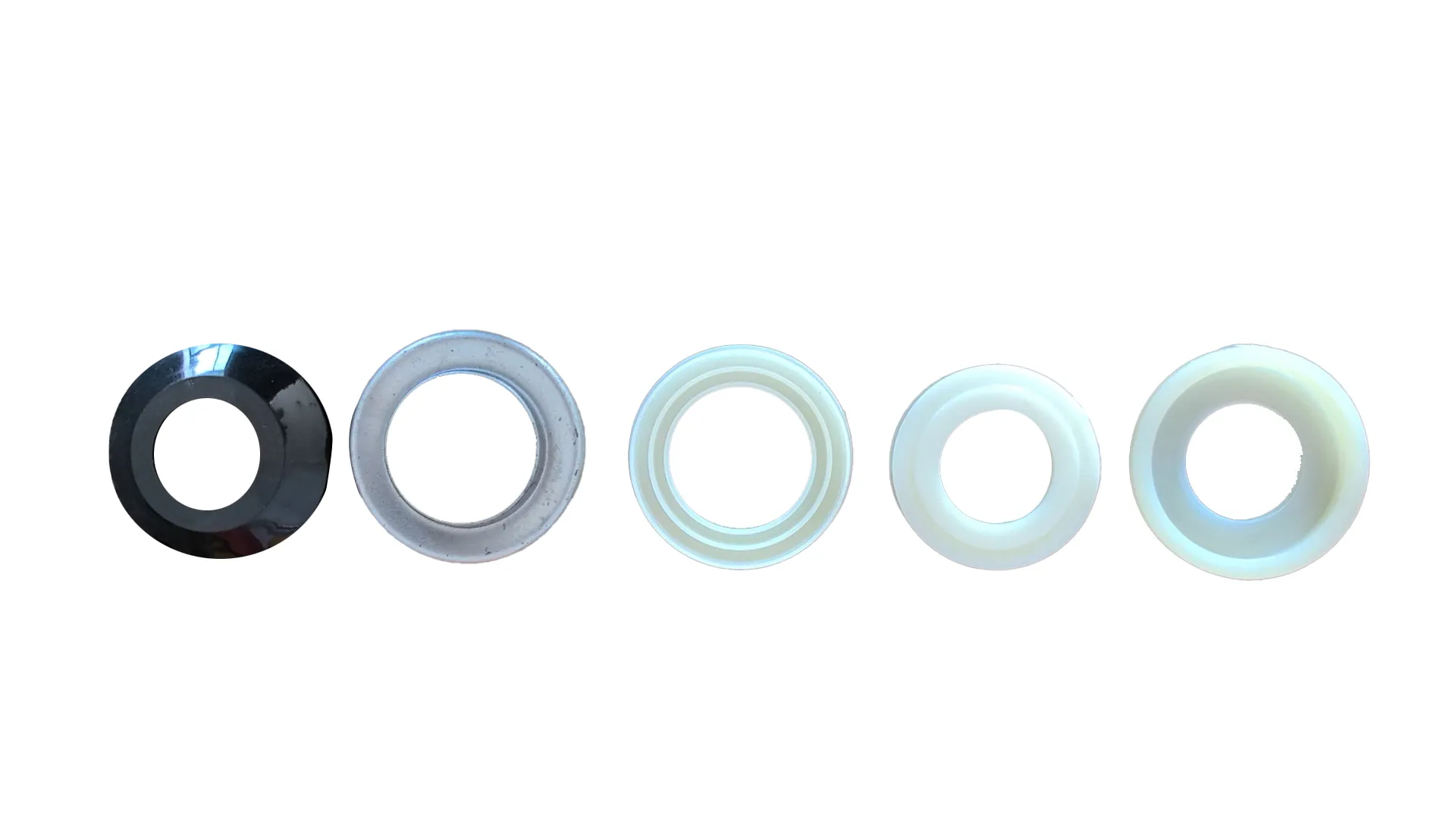

The design of return pulleys is engineered to accommodate specific loads and angles of operation. For heavy-duty applications, return pulleys are often made of robust materials such as steel or reinforced plastics to withstand the stresses involved. The size and diameter of a return pulley can also affect the overall efficiency of the system. Larger pulleys may reduce friction and energy loss, while smaller ones can fit into tighter spaces, providing versatility in engineering designs.

In addition to their physical characteristics, return pulleys also come in various configurations, including fixed and adjustable types. Fixed pulleys are commonly used in static installations, while adjustable pulleys provide flexibility in dynamic environments where load conditions may change. This adaptability is crucial in industries such as mining, construction, and manufacturing, where operational demands fluctuate.

Furthermore, the integration of return pulley systems into automated machinery enhances productivity. For instance, in assembly lines, return pulleys streamline the movement of products, ensuring that items move efficiently from one station to another without interruption. This not only speeds up production but also improves the overall workflow.

In conclusion, return pulleys are indispensable components in mechanical systems. Their ability to redirect cables and belts, reduce wear, and enhance the efficiency of operations makes them essential in many industries. Understanding the importance of return pulleys can lead to better designs and improved performance in various mechanical applications. As technology advances, the role of return pulleys will continue to evolve, further cementing their status as vital elements in engineering and manufacturing.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025