Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

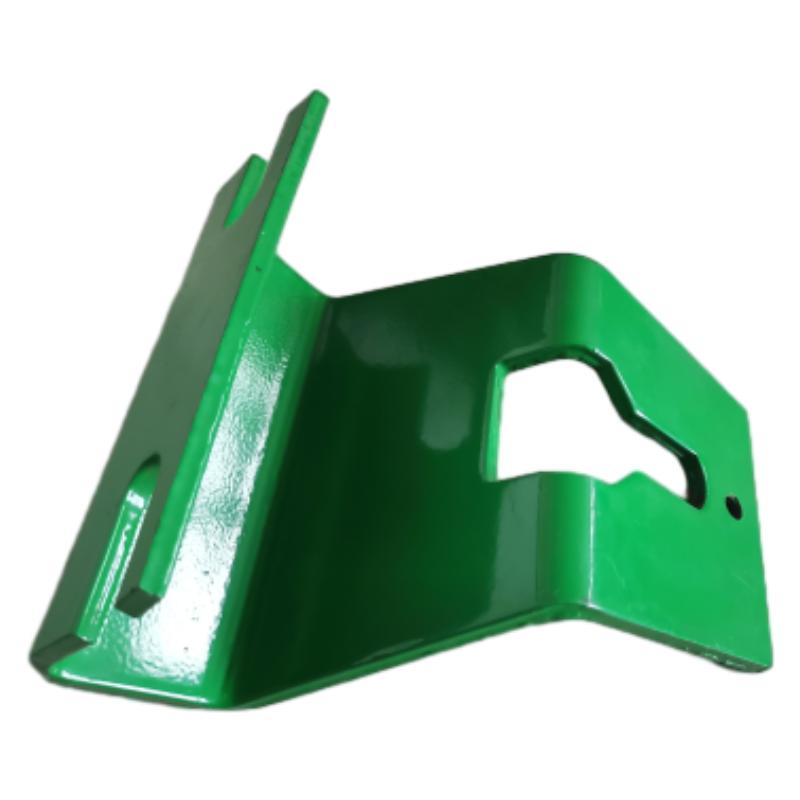

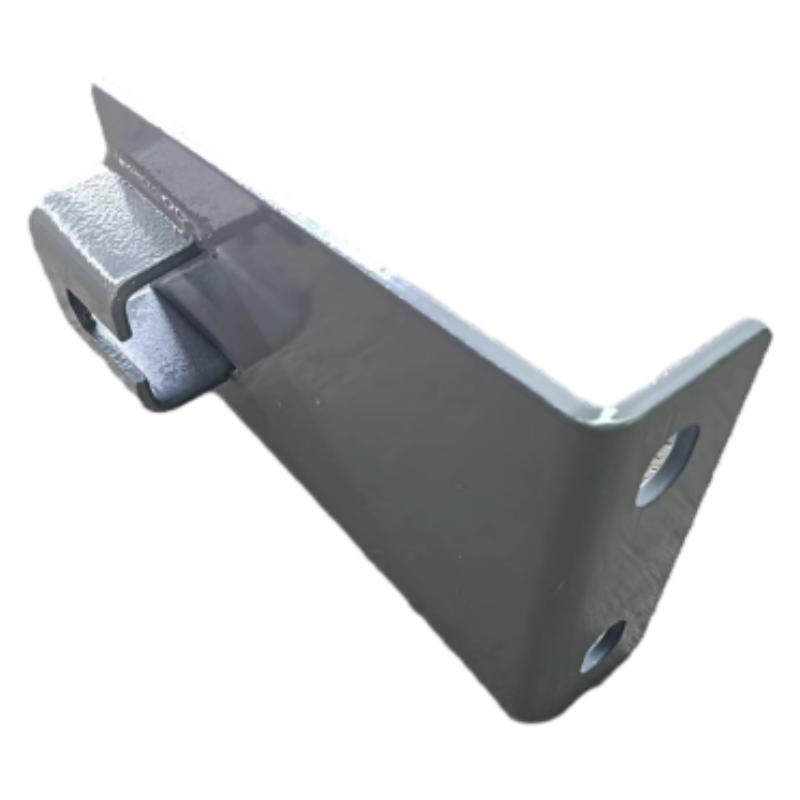

Zulu Return Idler Bracket | Heavy-Duty, Easy-Install

Return Idler Bracket is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Manufacturing of conveying machinery. This article explores how Yanshan Aohua Machinery Equipment Manufacture Limited Company supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Return Idler Bracket Overview

- Benefits & Use Cases of Return Idler Bracket in Manufacturing of conveying machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Return Idler Bracket from Yanshan Aohua Machinery Equipment Manufacture Limited Company

Return Idler Bracket Overview

A Return Idler Bracket securely mounts return-side conveyor rollers to the stringer or gantry, stabilizing the belt on its empty run and preventing sag, edge damage, and mis-tracking. In the Manufacturing of conveying machinery, this seemingly simple component is vital: it aligns with rollers and brackets to preserve belt life, maintain throughput, and minimize downtime. Yanshan Aohua Machinery Equipment Manufacture Limited Company engineers brackets as robust conveyor accessories, designed to interface cleanly with standard conveyor roller parts and frames across mining, aggregates, cement, power, steel, and port terminals.

- Relevance: the bracket absorbs structural loads from return rollers, maintaining belt path and reducing vibration that can accelerate wear across the conveyor system.

- Technical background: offered in flat-return and V-return configurations, with options such as slotted mounting holes for precise alignment, galvanization or powder coating for corrosion resistance, and compatibility with common roller diameters and shaft types.

- Manufacturer credibility: Yanshan Aohua supplies repeatable, high-tolerance fabrications backed by rigorous QC, providing reliable fit with roller housings, conveyor hanger assemblies, and other structural supports.

Benefits & Use Cases of Return Idler Bracket in Manufacturing of conveying machinery

From quarry conveyors to high-capacity bulk terminals, the Return Idler Bracket is integral to system stability. Use cases include long overland belts, transfer points susceptible to carryback, and reversing conveyors where belt control is critical. Engineered brackets help maintain optimal belt line, reduce flutter on the return strand, and support sealing systems, improving dust control and safety.

- Applications: mining and aggregates (abrasive duty), cement and lime (dusty, alkaline), power and steel (high-temperature surroundings), logistics centers (continuous operation). They interface seamlessly with conveyor roller parts and other conveyor accessories.

- Competitive advantages: rigid geometry for tracking accuracy; slotted or pre-drilled patterns for fast install; coatings for corrosion protection; options for V-return to improve belt centering; compatibility with existing rollers and brackets to simplify retrofits.

- Aohua expertise: practical designs developed from field feedback help maintenance teams upgrade brackets without altering frames or conveyor hanger positions, shortening shutdown windows and cutting installation risk.

Cost, Maintenance & User Experience

Total cost of ownership for a Return Idler Bracket hinges on durability, installation time, and the frequency of roller change-outs. Aohua focuses on robust steel sections and protective finishes to extend service life, reduce corrosion-related failures, and maintain alignment under load. Standardized hole patterns and accessible fastener positions streamline swap-outs—helping crews replace rollers quickly while minimizing lockout time and production loss.

- ROI drivers: fewer unplanned stops, extended belt life from improved tracking, simplified inventory through bracket commonality, and reduced labor for inspections.

- Maintenance guidance: schedule torque checks for mounting bolts, inspect contact points for wear or corrosion, and verify alignment after roller replacement. Clear access around the bracket makes housekeeping easier, supporting belt-cleanliness targets and safer walkways.

Sustainability & Market Trends in manufacturing

Sustainability in bulk materials handling increasingly emphasizes durability, maintainability, and responsible material choices. A long-life Return Idler Bracket lowers resource use by reducing replacement frequency and scrap. Corrosion-resistant finishes extend intervals between overhauls, supporting energy-efficient, steady-state operation with fewer emergency shutdowns. Additionally, well-aligned belts reduce spillage and dust, aiding environmental compliance and housekeeping goals.

- Market trends: standardization across conveyors to simplify spares, modular upgrades to extend legacy assets, and data-driven maintenance to prevent failures at return strands and idler stations.

- Aohua’s approach: forward-thinking designs compatible with modern rollers and brackets, eco-conscious coating options, and fabrication practices aimed at consistent quality. As a trusted manufacturer of conveyor accessories, Yanshan Aohua helps operators meet both production and sustainability objectives.

Conclusion on Return Idler Bracket from Yanshan Aohua Machinery Equipment Manufacture Limited Company

For B2B decision makers in the Manufacturing of conveying machinery, the Return Idler Bracket is a small component with a large operational impact. It stabilizes the belt, reduces wear, and streamlines maintenance across demanding environments. Yanshan Aohua Machinery Equipment Manufacture Limited Company delivers dependable brackets engineered to integrate with conveyor roller parts, conveyor hanger supports, and wider rollers and brackets assemblies, helping teams hit uptime and safety targets. Contact us: email: sales1@hebeiaohua.com. Visit our website: https://www.idleraohua.com

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025