Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

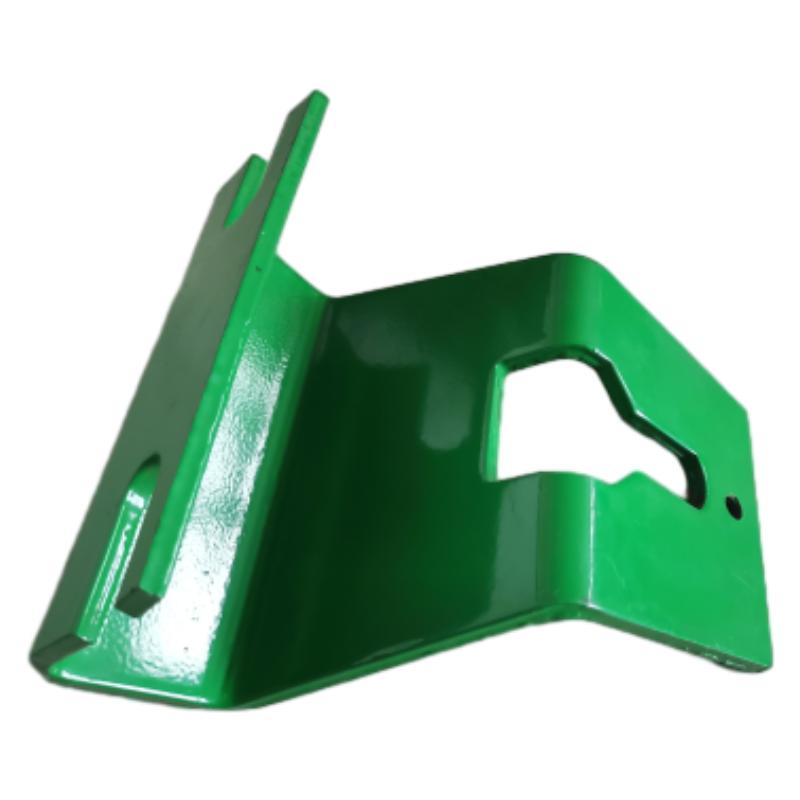

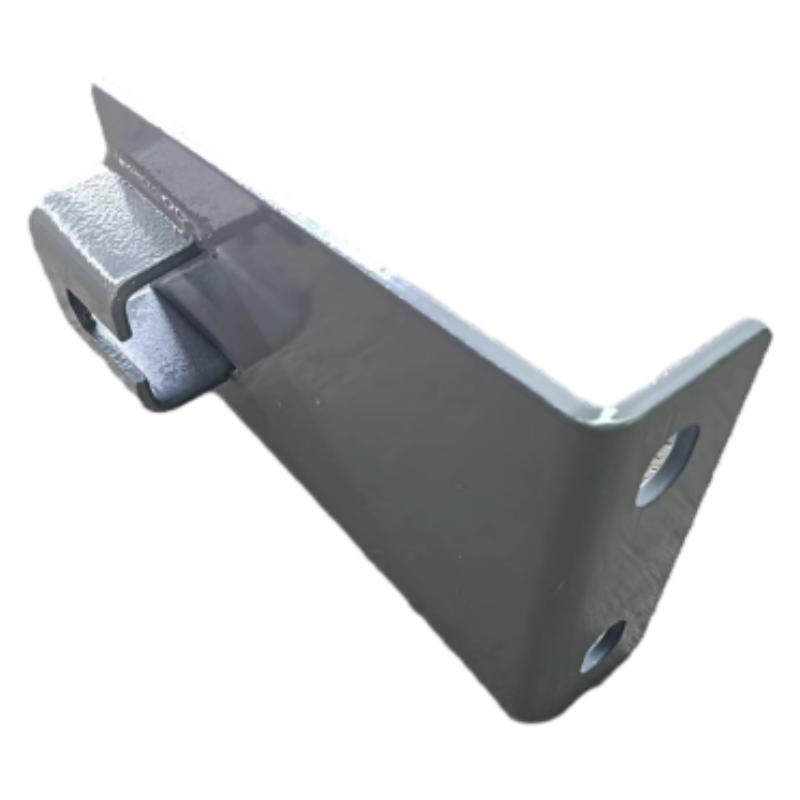

Zulu Return Idler Bracket – Heavy-Duty, Corrosion-Resistant

Return Idler Bracket is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Manufacturing of conveying machinery. This article explores how Yanshan Aohua Machinery Equipment Manufacture Limited Company supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Return Idler Bracket Overview

- Benefits & Use Cases of Return Idler Bracket in Manufacturing of conveying machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Return Idler Bracket from Yanshan Aohua Machinery Equipment Manufacture Limited Company

Return Idler Bracket Overview

A Return Idler Bracket is the structural mount that supports return-side rollers beneath a conveyor belt, keeping the belt tracking true and minimizing sag, wear, and energy loss. In the Manufacturing of conveying machinery, these brackets are critical conveyor accessories that connect rollers and brackets into a rigid, reliable support system. Engineered for harsh environments across mining, aggregates, cement, ports, and power, a quality bracket aligns the conveyor roller parts with precision, stabilizes belt trajectory, and reduces maintenance events.

Yanshan Aohua Machinery Equipment Manufacture Limited Company manufactures Return Idler Brackets using heavy‑gauge steel, optional Q235/Q345 materials, and corrosion-resistant finishes such as hot-dip galvanizing or powder coating. Slotted mounting holes simplify on-site adjustment; reinforced ribs increase stiffness; and edge folds help resist deformation under load. Brackets are available to suit common belt widths and standards (DIN/CEMA-compatible) and integrate cleanly with conveyor hanger frames and return rollers. For OEMs and retrofit projects alike, Aohua’s dimensional accuracy and consistent hole patterns streamline installation and reduce downtime. Explore specifications and options on the product page to match your duty class, belt width, and environment.

Benefits & Use Cases of Return Idler Bracket in Manufacturing of conveying machinery

From bulk material handling lines to high-throughput process plants, Return Idler Brackets are deployed wherever belt stability and uptime are non-negotiable. Typical applications include tail sections, long overland runs, and transfer points where belt slack and mistracking can accelerate wear. In new-builds, engineers specify Aohua brackets to standardize rollers and brackets across lines; in retrofits, maintenance teams use them to upgrade legacy frames and improve alignment without altering main stringers. Their compatibility with common conveyor hanger arrangements ensures seamless integration.

- Precision alignment: slotted holes and machined faces help center the return roller, maintaining belt tracking and reducing edge fray.

- Strength and stability: heavy-duty profiles and ribbed designs resist vibration and dynamic loads in demanding duty cycles.

- Corrosion resistance: hot-dip galvanized or powder-coated finishes extend service life in coastal, chemical, or wet conditions.

- Interchangeability: works with standard conveyor roller parts and a broad range of return rollers to simplify spares management.

Backed by decades in the Manufacturing of conveying machinery, Yanshan Aohua provides consistent quality control, quick-turn production, and engineering support. The result is a Return Idler Bracket that helps B2B decision makers reduce risk, consolidate suppliers, and standardize critical conveyor accessories across multiple facilities.

Cost, Maintenance & User Experience

Total cost of ownership hinges on more than the purchase price. The right Return Idler Bracket lowers lifetime costs by shortening installation time, reducing belt wear through better tracking, and minimizing unplanned stops. Aohua’s brackets ship ready-to-install with consistent hole geometry, cutting field modifications and labor. Durable coatings and robust section design extend service intervals, while interchangeability with standard conveyor roller parts simplifies spares and inventory. These factors combine to deliver strong ROI for operations measured on throughput and availability.

- Maintenance: periodic visual checks of fasteners and roller rotation; quick alignment tweaks via slotted holes.

- Durability: heavy-gauge steel and protective finishes resist impact, abrasion, and corrosion, extending service life.

- User feedback: plant teams report smoother belt travel, fewer tracking interventions, and simplified changeouts compared to non-standard brackets.

For B2B buyers consolidating vendors, Yanshan Aohua Machinery Equipment Manufacture Limited Company offers stable lead times, consistent quality, and documentation aligned with DIN/CEMA practices—further reducing procurement complexity and lifecycle risk.

Sustainability & Market Trends in manufacturing

Sustainability in conveyor systems increasingly focuses on energy efficiency, durability, and material circularity. Proper belt tracking—enabled by robust Return Idler Brackets—reduces friction losses and cuts power consumption. Longer-lasting components mean fewer changeouts and less waste. Finishes such as low‑VOC powder coating and hot-dip galvanizing deliver extended corrosion protection, supporting longer service intervals and better lifecycle performance. Standardized designs ease end-of-life recycling and refurbishing of rollers and brackets assemblies.

Regulatory pressure and ESG reporting are driving adoption of reliable conveyor accessories that improve safety and uptime. Yanshan Aohua Machinery Equipment Manufacture Limited Company aligns with these trends by emphasizing design-for-maintenance, robust coatings, and consistent quality systems. With market demand rising across mining, bulk terminals, and process industries, forward‑thinking buyers choose components that integrate seamlessly with conveyor hanger frames, support predictive maintenance, and help achieve operational decarbonization targets.

Conclusion on Return Idler Bracket from Yanshan Aohua Machinery Equipment Manufacture Limited Company

A well-engineered Return Idler Bracket is essential to reliable belt tracking, reduced wear, and lower energy use across the General equipment manufacturing industry and the Manufacturing of conveying machinery. Yanshan Aohua Machinery Equipment Manufacture Limited Company delivers durable, installation-friendly brackets that integrate with standard conveyor accessories and streamline maintenance for B2B operations. Backed by manufacturing expertise and consistent quality, Aohua is a trusted partner for OEMs and end users planning standardized upgrades or new builds.

- Choose proven performance and compatibility with your rollers and brackets and conveyor hanger setups.

- Reinforce uptime with robust, corrosion-resistant brackets designed for demanding duty.

- Strong CTA: Contact us: email: sales1@hebeiaohua.com — Visit our website: https://www.idleraohua.com

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025