Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu pu pulley

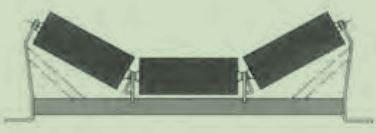

Understanding PU Pulleys An Overview of Their Structure and Applications

PU pulleys, or polyurethane pulleys, are specialized components widely utilized in various mechanical systems, especially in the fields of industrial machinery, automotive engineering, and robotics. Their unique material properties and design make them highly effective for specific applications where durability, low weight, and efficiency are paramount.

What is a PU Pulley?

A PU pulley is typically made from polyurethane, a versatile polymer known for its resilience, flexibility, and resistance to wear and tear. Unlike traditional materials like metal or plastic, polyurethane offers a combination of hardness and elasticity. This property allows PU pulleys to operate smoothly under high loads while maintaining their shape and functionality over time.

Key Features and Advantages of PU Pulleys

1. Durability One of the standout features of PU pulleys is their exceptional durability. They can withstand harsh environmental conditions, including exposure to chemicals, UV light, and extreme temperatures, making them ideal for outdoor or industrial applications.

2. Noise Reduction PU pulleys generate less noise compared to metal options, making them suitable for environments where sound levels must be minimized. This is particularly beneficial in settings such as manufacturing plants or warehouses where loud machinery can lead to worker distraction or discomfort.

3. Lightweight PU pulleys are significantly lighter than their metal counterparts, reducing the overall weight of machinery and improving operational efficiency. This quality is especially advantageous in applications like robotics, where weight reduction can enhance performance and mobility.

4. Cost-Effective While PU materials can sometimes be more expensive initially, their longevity and reduced maintenance needs often translate to lower lifecycle costs. Users find that investing in PU pulleys can yield significant savings over time.

pu pulley

Applications of PU Pulleys

PU pulleys have a wide array of applications across different industries. Here are a few notable examples

- Manufacturing In assembly lines, PU pulleys are employed in conveyor systems to facilitate the smooth movement of products. Their durability ensures minimal downtime, contributing to increased productivity.

- Automotive In the automotive industry, PU pulleys are often used in power transmission systems. They are perfect for applications requiring high tensile strength and flexibility, such as timing belts and tensioners.

- Robotics The lightweight and flexible nature of PU pulleys makes them an excellent choice for robotics. They are frequently used in robotic arms and automated systems to enhance movement accuracy and efficiency.

- Agriculture PU pulleys are also found in agricultural equipment, where they can withstand exposure to various environmental factors while supporting the efficient operation of machines like tractors and harvesters.

Conclusion

In summary, PU pulleys exemplify the intricate balance between material science and engineering application. Their unique attributes such as durability, lightweight design, and noise reduction capabilities make them a preferred choice in numerous industrial sectors. As technology continues to advance, the role of PU pulleys in enhancing machinery efficiency and reliability is likely to grow. By understanding their features and advantages, industries can make informed decisions that contribute to better operational performance and long-term cost savings. As we move forward, the continued exploration of innovative materials like polyurethane will undoubtedly pave the way for even more advanced pulley systems, further revolutionizing the way we approach mechanical engineering challenges.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025