Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu pu pulley

Understanding Pu Pulley A Comprehensive Overview

The pu pulley, often referred to simply as a “pulley,” is a fundamental mechanical device that plays a crucial role in various applications across different industries. Its simplicity in design, combined with its effectiveness in lifting and moving loads, has made it an essential tool in engineering, construction, and even everyday tasks. In this article, we will explore the characteristics, applications, and advantages of pu pulleys, shedding light on why they remain a popular choice for lifting mechanisms.

What is a Pu Pulley?

A pu pulley is a type of pulley that features a groove or channel designed to hold a rope or cable. The primary purpose of a pulley is to change the direction of force applied to lift a load or to facilitate movement. The pu in the term can refer to the material or the specific type of pulley configuration, but it generally relates to pulleys that involve polyurethane (PU) components, which offer durability and flexibility.

These pulley systems can come in various forms, including single pulleys, double pulleys, block and tackle systems, and more, each designed to serve specific lifting needs and load capacities.

How Does a Pu Pulley Work?

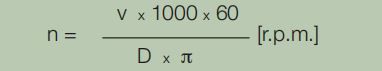

The operation of a pu pulley is based on the principles of mechanical advantage

. When a force is applied to one end of a rope that runs through a pulley, it allows the user to lift a load that would otherwise be too heavy to move manually. The pulley reduces the amount of force needed to lift a weight by allowing the force to be distributed over a longer distance.For example, in a simple setup with a single pulley, if you pull down with a force of 10 pounds on one side of the rope, the pulley enables you to lift a load of up to 10 pounds on the other side with minimal effort. However, the distance you need to pull down the rope will be twice the distance that the load is lifted.

pu pulley

Applications of Pu Pulleys

Pu pulleys are versatile and can be found in a wide array of applications. In construction, they are commonly used for hoisting materials to heights safely and efficiently. They are also vital in shipping and logistics, where heavy containers need to be moved and secured.

In the realm of sports and fitness, pulleys are utilized in various workout machines to create resistance training systems that are adjustable and user-friendly. Additionally, in the entertainment industry, rigging systems for theaters and events rely on pulleys for the smooth operation of stage props and scenery.

Advantages of Using Pu Pulleys

One of the primary advantages of pu pulleys is their ability to reduce the amount of force needed to lift heavy loads. This mechanical advantage not only makes tasks easier but also enhances safety, as it minimizes the risk of injury from heavy lifting. The use of durable materials like polyurethane in pu pulleys also contributes to their longevity and reliability, ensuring they perform well under load.

Moreover, pulleys are relatively inexpensive compared to other lifting systems, making them accessible for both industrial applications and home use. Their simplicity in design means they require minimal maintenance and can be easily integrated into existing systems.

Conclusion

In conclusion, pu pulleys are indispensable mechanical devices that facilitate lifting and movement across various industries. Their ability to provide mechanical advantage, combined with the durability and flexibility offered by materials like polyurethane, makes them a preferred choice for many applications. Whether in construction, logistics, fitness, or entertainment, the functionality of pu pulleys cannot be overstated. Understanding their operation and advantages can help users make informed decisions about incorporating these versatile tools into their projects. As technology continues to evolve, it is likely that the design and application of pulleys will also advance, ensuring their relevance for years to come.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025