Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Understanding the Mechanics and Applications of Pulley Systems for Efficient Lifting

The Evolution and Importance of the Pulley Tail in Mechanical Systems

In the realm of mechanical systems and engineering design, pulleys have long been recognized as vital components that facilitate the movement of loads with efficiency and ease. Among various elements associated with pulleys, the pulley tail signifies a crucial aspect worthy of exploration. This article delves into the evolution, importance, and applications of the pulley tail, illustrating its significance in both historical and contemporary contexts.

Understanding the Pulley and Its Components

At its core, a pulley is a simple machine that consists of a wheel and a rope or cable. The pulley tail refers specifically to the part of the rope or cable that extends beyond the wheel. It plays a critical role in loading and unloading situations, acting as a connector between the load and the pulley system. The design and configuration of the pulley tail can significantly affect the efficiency and effectiveness of the entire system.

Historically, the concept of the pulley dates back to ancient civilizations. The earliest records point to the Mesopotamians and Egyptians, who utilized basic pulley systems to lift heavy stones and construct monumental architectures. As engineering progressed through the ages, the design and utilization of pulleys evolved, giving rise to more sophisticated systems that incorporated the pulley tail in various applications.

The Functionality of the Pulley Tail

The pulley tail serves several essential functions in both manual and mechanical systems. Primarily, it provides a means to increase the mechanical advantage when lifting heavy objects. By adjusting the length and configuration of the pulley tail, engineers can minimize the force needed to lift a load. This principle is especially useful in construction, shipping, and rescue operations, where heavy lifting is often required.

Furthermore, the pulley tail plays a significant role in stability and control

. A well-designed pulley system with a properly configured pulley tail ensures that the load remains balanced and can be maneuvered with precision. This is particularly important in scenarios such as crane operations, where the risk of dropping the load can lead to dangerous situations and costly damages.pulley tail

Modern Applications and Innovations

In modern engineering and design, the applications of pulley tails have become increasingly diversified. The entertainment industry, for instance, relies heavily on pulley systems for stage set-ups and rigging. The ability to swiftly raise and lower stage equipment while maintaining safety standards showcases the essential function of the pulley tail.

In the field of sports, pulley systems are utilized in gym equipment, aiding in resistance training. The adjustable pulley beds allow users to customize their workout intensity, showcasing the mechanical advantage provided by the pulley tail. Additionally, modern innovations in materials science have led to the development of stronger and lighter ropes and cables, thus enhancing the performance of pulley systems.

Transport systems, including elevators and escalators, also illustrate the significance of the pulley tail. These systems rely on a series of pulleys to ensure smooth and efficient movement, whether for lifting people between floors or transporting goods. In this context, the pulley tail not only facilitates movement but also plays an integral role in safety mechanisms.

Conclusion

As a fundamental component of numerous mechanical systems, the pulley tail exemplifies the intricate balance between design, function, and safety. From its ancient origins to its contemporary applications, the evolution of the pulley tail reflects advancements in engineering and technology, highlighting its importance in various sectors, including construction, entertainment, sports, and transportation.

The ongoing exploration of pulley systems continues to inspire innovations that enhance efficiency and safety, ensuring that the legacy of the pulley tail remains relevant in the future. As engineers and designers push the boundaries of the possible, the humble pulley tail will continue to be a cornerstone of mechanical design, demonstrating that even the simplest components can have significant impacts on functionality and performance.

-

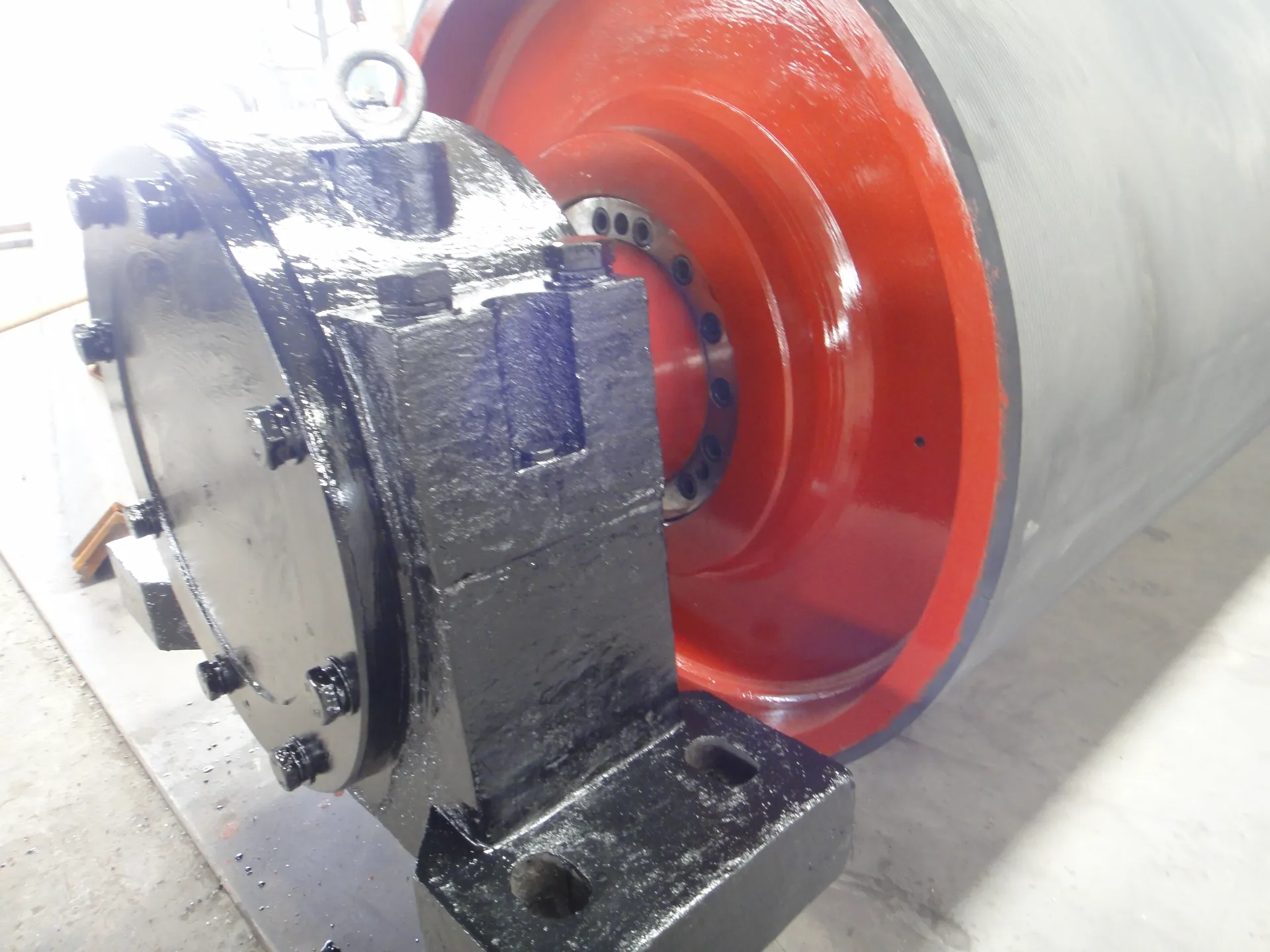

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025