Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu pulley rubber

The Versatility and Importance of Pulley Rubber in Modern Applications

Pulleys are ubiquitous mechanical devices used to lift or move loads efficiently. Among the various components that make up a pulley system, rubber plays a crucial role, particularly in the form of rubber pulleys or rubber-coated pulleys. These components are essential across various industries, providing not only functionality but also enhanced performance, durability, and safety.

The Material Rubber

Rubber is a highly flexible and resilient material, which makes it an ideal choice for applications requiring durability and adaptability. Its ability to stretch without breaking and return to its original shape allows it to absorb shocks and vibrations, acting as a cushion in many mechanical systems. This is particularly beneficial in pulley systems where load changes frequently occur, ensuring smooth operation under varying conditions.

Applications of Rubber in Pulleys

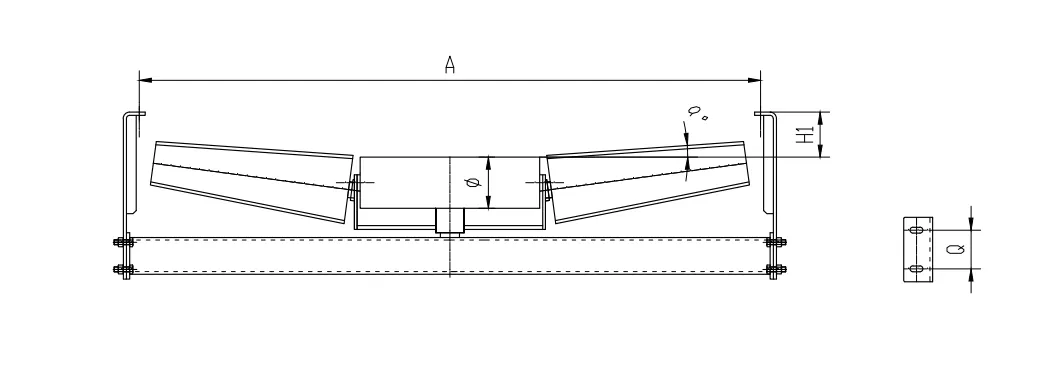

1. Industrial Machinery One of the primary applications of rubber pulleys is in industrial machinery. In conveyor systems, rubber-coated pulleys afford excellent grip on belts, preventing slippage and ensuring smooth operation. Their ability to accommodate significant weight while reducing noise and vibration enhances the overall efficiency of material handling processes.

2. Automotive Industry In automobiles, rubber pulleys are used in various applications, including timing belts and accessory drive systems. The elasticity of rubber helps in maintaining tension in the belts, which is crucial for the synchronized operation of engine components. Additionally, rubber pulleys contribute to noise reduction and improved fuel efficiency, representing a win-win for manufacturers and consumers alike.

3. Agricultural Equipment In agriculture, rubber pulleys are utilized in machinery for planting, harvesting, and processing crops. The resilience of rubber helps these machineries operate efficiently under harsh conditions. Moreover, rubber pulleys are often preferred for their ability to withstand exposure to chemicals and environmental abrasives found in agricultural settings.

4. Exercise Equipment Rubber pulleys are commonly found in fitness and exercise machines. They provide a smooth and adjustable resistance, allowing users to perform various workouts safely and effectively. The use of rubber minimizes the risk of injury from sudden jerks or snaps, making workouts not only efficient but also safer for users of all levels.

pulley rubber

Advantages of Rubber Pulleys

- Enhanced Performance The elasticity of rubber allows pulleys to maintain consistent performance even under high stress. This reliability is critical in applications where precision is necessary.

- Noise Reduction Rubber's ability to absorb vibrations significantly reduces noise in mechanical systems, making machinery more pleasant to operate and reducing environmental noise pollution.

- Corrosion Resistance Rubber's resistance to moisture and many chemicals helps to prolong the life of the pulleys in diverse operating environments, making them suitable for both indoor and outdoor applications.

- Cost-Effective Although rubber can have a higher initial cost compared to some alternatives, its durability and performance often result in lower overall maintenance and replacement costs.

Future of Pulley Rubber Technology

As industries evolve, so too does the technology surrounding rubber pulleys. Innovations in materials science have led to the development of advanced rubber composites that enhance performance characteristics such as heat resistance and load-bearing capacity. Additionally, the integration of smart technologies into pulley systems is on the rise, which could lead to more efficient predictive maintenance and operational monitoring.

Conclusion

In summary, rubber is a vital material in the construction of pulley systems across various industries. Its unique properties provide advantages that enhance performance, safety, and durability. As technology advances, it is likely that we will see even greater innovations in rubber pulley applications, further solidifying their importance in the mechanical world. Whether in industrial machinery, automotive applications, or fitness equipment, rubber pulleys will continue to play a pivotal role in enhancing efficiency and performance, demonstrating that sometimes, the simplest materials can have the most profound impact.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025