Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 13, 2025 20:00

Back to list

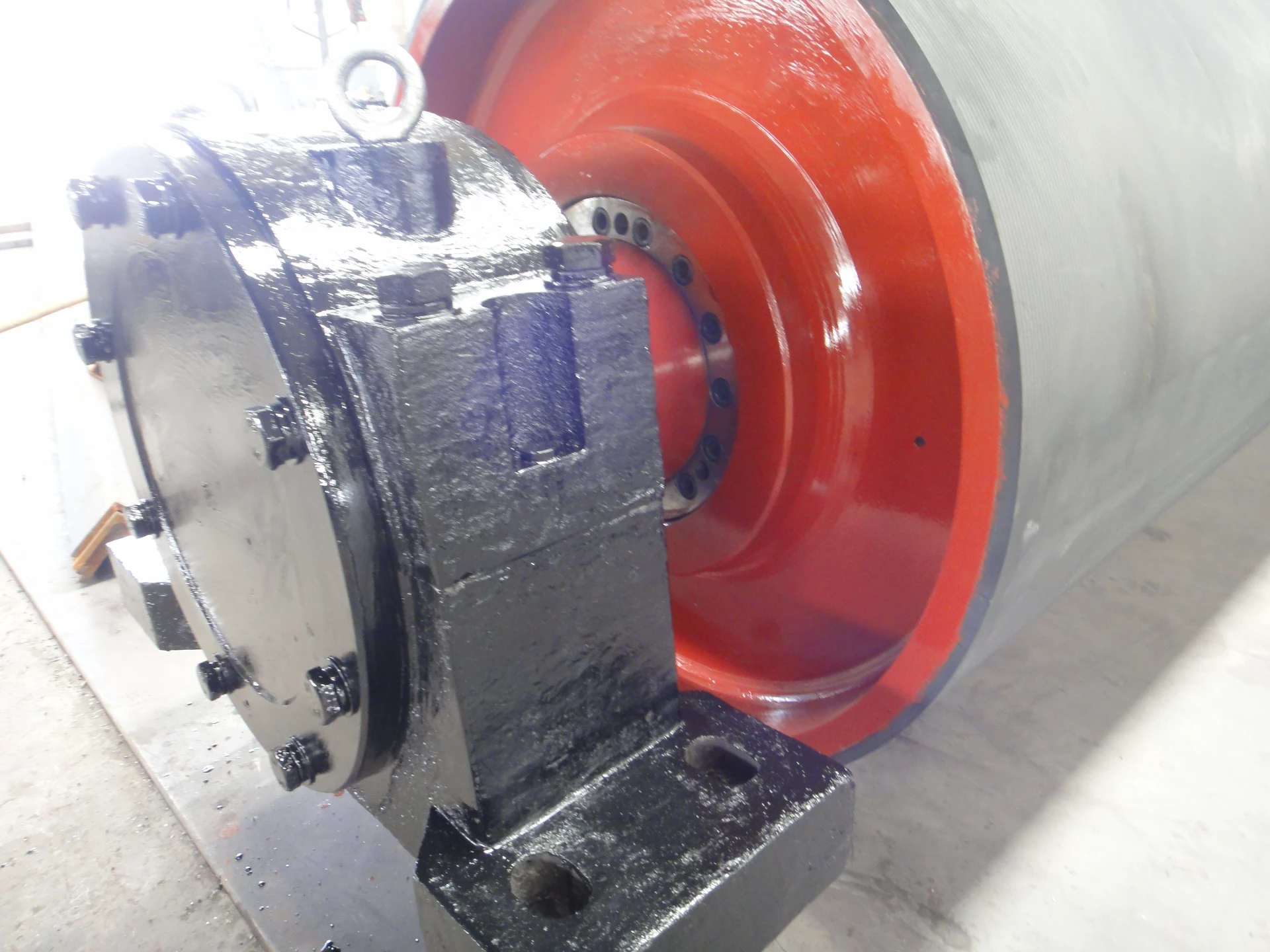

Customized Roller

When it comes to enhancing the efficiency and longevity of industrial machinery, PU coated rollers are indispensable. With exceptional durability and adaptability, these rollers cater to a variety of applications across multiple industries. The unique properties of polyurethane (PU) coatings set them apart, making them a crucial component for businesses looking to optimize their operations.

As customizability is increasingly valuable in modern industrial applications, PU coated rollers do not disappoint. They are available in a wide range of hardness levels and can be tailor-made to specific dimensions and configurations, meeting the exact requirements of diverse applications. This customization ensures optimal performance and integration, making them a flexible solution for complex production environments. Expertise in the development and application of PU coated rollers means ongoing improvements in materials and technologies, resulting in even more durable and efficient products. Authoritative manufacturers continuously invest in research and development, ensuring that their rollers not only meet but exceed industry standards. This commitment to innovation underscores the reliability and trustworthiness of PU coated roller solutions available in the market today. Investment in PU coated rollers is not merely an expenditure on machinery components but a strategic move towards enhanced performance and sustainability. Companies implementing these rollers experience a marked improvement in productivity and operational efficiency, positively impacting their bottom line. By choosing PU coated rollers, businesses are also demonstrating a commitment to quality and precision. In conclusion, the adoption of PU coated rollers is a forward-thinking decision rooted in experience and expertise. Their advantages in terms of durability, performance, and efficiency are backed by authoritative research and proven results. For any industry seeking to optimize its processes while ensuring reliability and integrity, PU coated rollers present a trustworthy and impactful solution.

As customizability is increasingly valuable in modern industrial applications, PU coated rollers do not disappoint. They are available in a wide range of hardness levels and can be tailor-made to specific dimensions and configurations, meeting the exact requirements of diverse applications. This customization ensures optimal performance and integration, making them a flexible solution for complex production environments. Expertise in the development and application of PU coated rollers means ongoing improvements in materials and technologies, resulting in even more durable and efficient products. Authoritative manufacturers continuously invest in research and development, ensuring that their rollers not only meet but exceed industry standards. This commitment to innovation underscores the reliability and trustworthiness of PU coated roller solutions available in the market today. Investment in PU coated rollers is not merely an expenditure on machinery components but a strategic move towards enhanced performance and sustainability. Companies implementing these rollers experience a marked improvement in productivity and operational efficiency, positively impacting their bottom line. By choosing PU coated rollers, businesses are also demonstrating a commitment to quality and precision. In conclusion, the adoption of PU coated rollers is a forward-thinking decision rooted in experience and expertise. Their advantages in terms of durability, performance, and efficiency are backed by authoritative research and proven results. For any industry seeking to optimize its processes while ensuring reliability and integrity, PU coated rollers present a trustworthy and impactful solution.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS