Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Prices for Belt Conveyor Rollers and Factors Influencing Their Cost in Industrial Applications

The Price Dynamics of Belt Conveyor Rollers An In-Depth Analysis

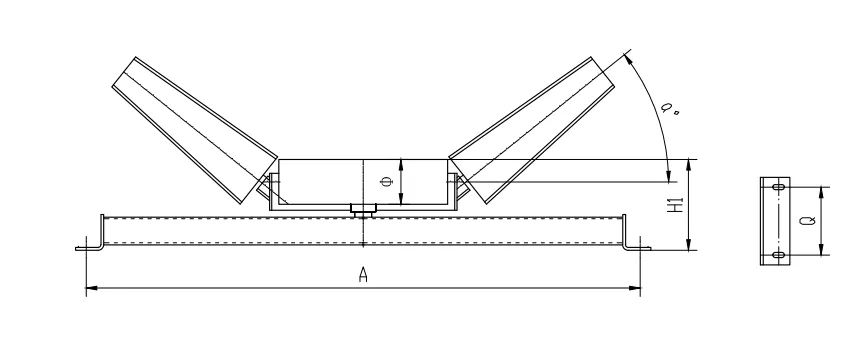

Belt conveyor systems play a pivotal role in various industries, facilitating the seamless movement of materials. At the heart of these systems lies a crucial component the conveyor roller. Understanding the price dynamics of belt conveyor rollers is essential for industries aiming for cost-effective solutions while ensuring operational efficiency.

Factors Influencing the Price of Conveyor Rollers

1. Material Composition Conveyor rollers are constructed from various materials, including steel, plastic, and aluminum. The choice of material significantly impacts the cost. Steel rollers, for instance, are often chosen for heavy-duty applications due to their strength and durability, making them more expensive than their plastic counterparts. Conversely, plastic rollers are lighter and resistant to corrosion, appealing for industries that prioritize weight reduction and resistance to harsh environments.

2. Roller Size and Specifications The dimensions of a conveyor roller also play a critical role in determining its price. Larger rollers capable of handling heavier loads will typically cost more due to the increased material and engineering requirements. Additionally, specialty rollers designed for specific applications, such as those with added features for enhanced lubrication or specific coatings, will also incur a higher price point.

3. Manufacturing Processes The complexity of the manufacturing process can affect the final price of conveyor rollers. Rollers produced through advanced techniques, such as precision machining or those incorporating innovative technologies for enhanced performance, may have higher upfront costs. However, these state-of-the-art rollers can often lead to lower maintenance costs and longer lifespans, presenting a compelling long-term value to industries.

4. Supplier and Market Demand The landscape of suppliers greatly influences pricing. Established manufacturers may offer premium products supported by extensive warranties and customer service, reflecting in higher prices. Conversely, newer suppliers may undercut prices to gain market share. Additionally, fluctuations in demand due to seasonal changes or economic conditions can lead to price variations, with increased demand often driving prices upward.

belt conveyor roller price

5. Geographic Location The geographic location of manufacturers and their customers can significantly impact costs. Transportation costs, import tariffs, and regional demand fluctuations all play a part in the final price. For instance, manufacturers located closer to major industrial hubs may have lower shipping costs, potentially allowing them to offer more competitive pricing.

Cost-Benefit Analysis for Industries

When selecting conveyor rollers, industries must balance initial costs with long-term benefits. Although cheaper rollers might seem appealing, they can lead to higher operational costs due to increased wear and tear or failure rates. Therefore, investing in higher-quality rollers might yield better returns, reducing downtime and maintenance expenses.

Market Trends and Future Outlook

As industries continue to evolve, so too do the demands placed on conveyor systems. The push towards automation and efficiency has led to innovations in roller design and functionality. Industry trends indicate a growing interest in eco-friendly materials and energy-efficient designs, which could influence future pricing structures. Companies that adapt to these trends and invest in quality will likely secure competitive advantages in their operational processes.

Conclusion

The price of belt conveyor rollers is influenced by a myriad of factors, including material composition, manufacturing processes, and market dynamics. For industries relying on these essential components, understanding these factors is crucial in making informed procurement decisions. Balancing cost with quality and longevity is key to achieving operational efficiency and sustainability in the long run. Investing wisely in high-quality conveyor rollers today will pave the way for improved productivity and reduced costs in the future.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025