Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 22, 2025 03:09

Back to list

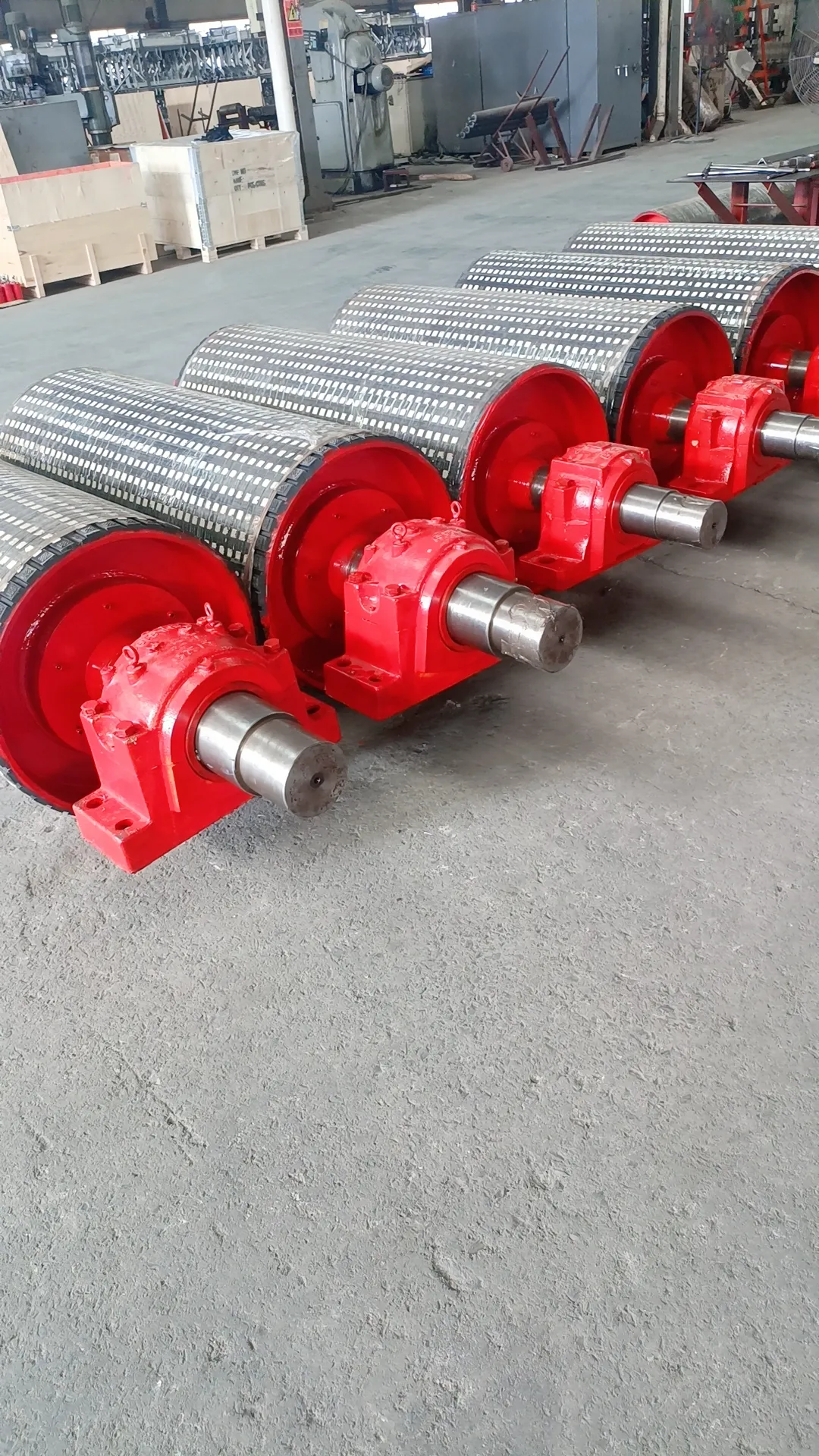

polyurethane idler rollers

Applying polyurethane with a roller can be a game-changer for those seeking a perfect finish on their woodworking projects or floors. As a seasoned expert in coating applications, let me delve into the nuances that make this method both efficient and effective, creating a shield of beauty and durability for your surfaces.

Application technique involves slow, deliberate rolling with minimal pressure. Start by rolling the polyurethane on in long, even strokes, maintaining a wet edge as you progress. This technique ensures uniformity and prevents lap marks that can occur if the edge dries before overlapping. Applying thin coats rather than thick ones allows for a faster drying process and reduced risk of imperfections. After applying each coat, patience is paramount. Allow the polyurethane to dry completely, which can take anywhere from four to 24 hours depending on the type used and environmental conditions. Once dry, lightly sanding with fine-grit sandpaper between coats promotes excellent adhesion for subsequent layers and a flawless finish. Be sure to clean up the dust thoroughly before applying the next coat. Typically, three coats of polyurethane strike the perfect balance between durability and aesthetics, but heavily trafficked areas might require an extra coat for added protection. The first coat may feel rough, but with each additional layer and sanding session, the surface will become progressively smoother, enhancing the natural beauty of the wood grain. In conclusion, applying polyurethane with a roller combines efficiency with effectiveness, providing a desirable finish for both amateur DIY enthusiasts and seasoned professionals. By meticulously selecting materials, preparing surfaces, and employing precise application techniques, one can achieve a professionally polished surface that stands the test of time. This method not only highlights the wood's innate beauty but also extends its longevity, creating a lasting impression of craftsmanship and care.

Application technique involves slow, deliberate rolling with minimal pressure. Start by rolling the polyurethane on in long, even strokes, maintaining a wet edge as you progress. This technique ensures uniformity and prevents lap marks that can occur if the edge dries before overlapping. Applying thin coats rather than thick ones allows for a faster drying process and reduced risk of imperfections. After applying each coat, patience is paramount. Allow the polyurethane to dry completely, which can take anywhere from four to 24 hours depending on the type used and environmental conditions. Once dry, lightly sanding with fine-grit sandpaper between coats promotes excellent adhesion for subsequent layers and a flawless finish. Be sure to clean up the dust thoroughly before applying the next coat. Typically, three coats of polyurethane strike the perfect balance between durability and aesthetics, but heavily trafficked areas might require an extra coat for added protection. The first coat may feel rough, but with each additional layer and sanding session, the surface will become progressively smoother, enhancing the natural beauty of the wood grain. In conclusion, applying polyurethane with a roller combines efficiency with effectiveness, providing a desirable finish for both amateur DIY enthusiasts and seasoned professionals. By meticulously selecting materials, preparing surfaces, and employing precise application techniques, one can achieve a professionally polished surface that stands the test of time. This method not only highlights the wood's innate beauty but also extends its longevity, creating a lasting impression of craftsmanship and care.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS