Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu polyurethane rollers with bearings

Polyurethane Rollers with Bearings A Comprehensive Overview

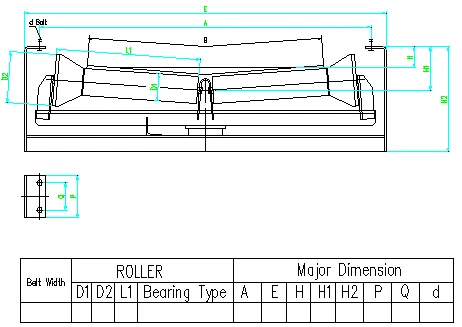

Polyurethane rollers with bearings have emerged as vital components across various industrial applications, significantly impacting performance, efficiency, and durability. These rollers are specially engineered to meet the demanding requirements of diverse sectors, including manufacturing, packaging, and logistics. In this article, we will explore the properties, benefits, and applications of polyurethane rollers with bearings, demonstrating why they are favored in modern industrial settings.

Understanding Polyurethane Rollers

Polyurethane is a versatile polymer known for its excellent mechanical properties, resilience, and durability. When manufactured into rollers, it combines the advantages of traditional materials like rubber and plastic while overcoming their limitations. Polyurethane rollers are hardened to withstand heavy loads and harsh environmental conditions, making them ideal for rigorous industrial applications.

The addition of bearings further enhances the functionality of these rollers. Bearings facilitate smooth rotation, reduce friction, and increase the overall efficiency of machinery. The synergy between polyurethane material and bearing technology creates a robust solution for various tasks, from transporting goods to processing materials.

Benefits of Polyurethane Rollers with Bearings

1. Durability and Longevity

One of the standout features of polyurethane rollers is their exceptional durability. Unlike conventional rubber rollers, which may wear out quickly under strain, polyurethane rollers have a prolonged lifespan. Their resistance to abrasion allows them to maintain their integrity even when subjected to repeated stress and heavy loads. This longevity results in reduced maintenance and replacement costs, making them a cost-effective choice for businesses.

2. Enhanced Load Capacity

Polyurethane rollers with bearings can handle significant loads without compromising performance. The combination of a strong polyurethane structure and the supporting bearings means these rollers can efficiently distribute weight, preventing deformation and enhancing operational stability. This load capacity is particularly essential in heavy-duty applications where reliability is crucial.

polyurethane rollers with bearings

The presence of bearings in polyurethane rollers significantly contributes to their operational smoothness. Bearings minimize friction and enable rollers to spin freely, which is vital in applications requiring high-speed movement. This smooth operation reduces wear and tear on both the rollers and the machinery they are part of, leading to increased efficiency and lower energy consumption.

4. Chemical Resistance

Polyurethane is known for its resistance to various chemicals and solvents. This characteristic makes polyurethane rollers particularly suitable for environments where exposure to harsh substances is common. They are less likely to degrade or become brittle over time, ensuring consistent performance in challenging conditions.

5. Customizability

Manufacturers often provide options to customize polyurethane rollers based on specific industrial needs. Clients can choose various cover hardness levels, diameters, and lengths, allowing them to tailor the rollers to fit particular applications. This flexibility ensures that businesses do not have to compromise on performance while accommodating unique operational requirements.

Applications of Polyurethane Rollers with Bearings

Polyurethane rollers with bearings find applications across numerous industries

- Manufacturing Used in conveyor systems, these rollers aid in the efficient movement of goods along production lines. - Packaging Rollers help with the transport of packaged items, ensuring smooth handling during the packing process. - Warehousing and Logistics In warehouses, these rollers are essential for the optimal functioning of moving equipment, such as pallet jacks and forklifts. - Food Processing Polyurethane's chemical resistance allows for safe use in environments where hygiene is critical.

Conclusion

In summary, polyurethane rollers with bearings are indispensable components in modern industrial applications. Their durability, load capacity, smooth operation, and resistance to chemicals make them the preferred choice for various sectors. As businesses strive for increased efficiency and reduced operational costs, the demand for high-quality polyurethane rollers will likely continue to grow. Investing in these advanced solutions not only enhances productivity but also contributes to the overall success of industrial operations.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025