Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 14, 2025 11:08

Back to list

Polyurethane Pulley(Polyurethane Lagging Pulley)

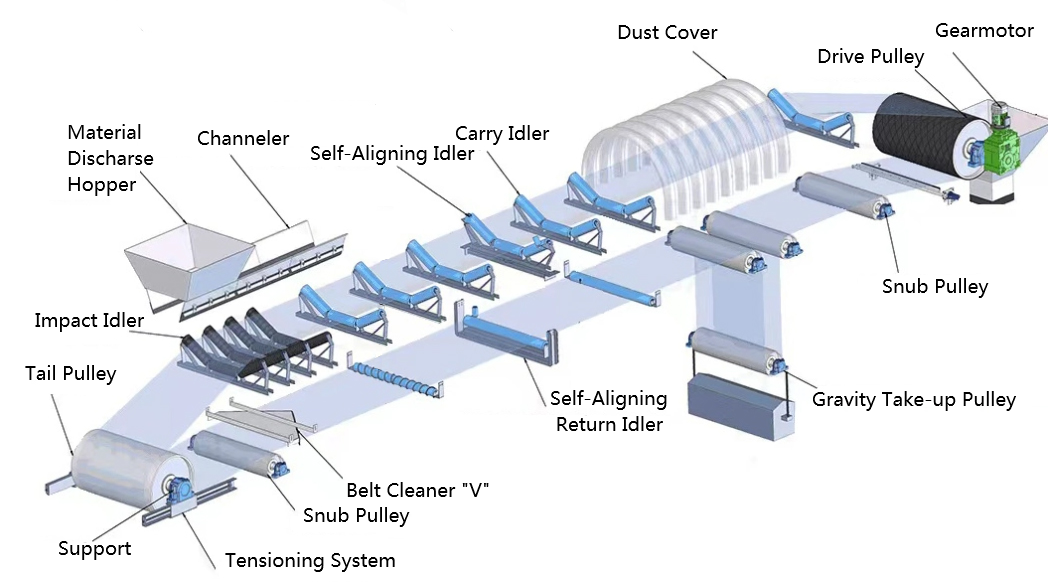

Lagged drum pulleys, a crucial component in conveyor systems, are often overlooked despite their critical function in ensuring the smooth operation of material handling processes. Drawing on years of expertise in the field, it is essential to delve into the intricate details that underscore the importance of choosing the right lagged drum pulley for your operations. This comprehensive guide aims to shed light on the value, functionality, and advantages of lagged drum pulleys, demonstrating their paramount relevance in industrial applications.

Authoritativeness in the realm of conveyor technology is founded on deep knowledge and an understanding of the dynamics at play. For instance, the design of a pulley—whether it employs a crown, flat, or winged design—affects the tracking and longevity of the belt. A crowned pulley, used extensively for its self-centering capability, can enhance belt alignment and thereby the overall efficiency of the conveyor system. By leveraging authoritative insights into these engineering nuances, operations can be optimized, ensuring a competitive edge in rigorous industrial environments. Trustworthiness is established not only through expertise and authoritativeness but also through demonstrating proven results and testimonials. Companies that have adopted high-quality lagged drum pulleys report a notable decrease in maintenance costs and system outages. Case studies abound where such components have delivered exceptional performance under strenuous conditions, instilling confidence in stakeholders who may initially be wary of investing in specialized equipment. Acknowledging this, manufacturers often provide extensive documentation and customer support to back the reliability and efficacy of their products. In conclusion, the choice of a lagged drum pulley is not merely a technical decision but a strategic one that can influence the operational efficiency and cost-effectiveness of your conveyor systems. By integrating experience, expertise, authoritativeness, and trustworthiness into the decision-making process, businesses can enhance their material handling capabilities. As the nexus between raw material movement and final product output, the right lagged drum pulley is an investment in the seamless continuity and success of industrial processes.

Authoritativeness in the realm of conveyor technology is founded on deep knowledge and an understanding of the dynamics at play. For instance, the design of a pulley—whether it employs a crown, flat, or winged design—affects the tracking and longevity of the belt. A crowned pulley, used extensively for its self-centering capability, can enhance belt alignment and thereby the overall efficiency of the conveyor system. By leveraging authoritative insights into these engineering nuances, operations can be optimized, ensuring a competitive edge in rigorous industrial environments. Trustworthiness is established not only through expertise and authoritativeness but also through demonstrating proven results and testimonials. Companies that have adopted high-quality lagged drum pulleys report a notable decrease in maintenance costs and system outages. Case studies abound where such components have delivered exceptional performance under strenuous conditions, instilling confidence in stakeholders who may initially be wary of investing in specialized equipment. Acknowledging this, manufacturers often provide extensive documentation and customer support to back the reliability and efficacy of their products. In conclusion, the choice of a lagged drum pulley is not merely a technical decision but a strategic one that can influence the operational efficiency and cost-effectiveness of your conveyor systems. By integrating experience, expertise, authoritativeness, and trustworthiness into the decision-making process, businesses can enhance their material handling capabilities. As the nexus between raw material movement and final product output, the right lagged drum pulley is an investment in the seamless continuity and success of industrial processes.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS