Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 19, 2025 10:35

Back to list

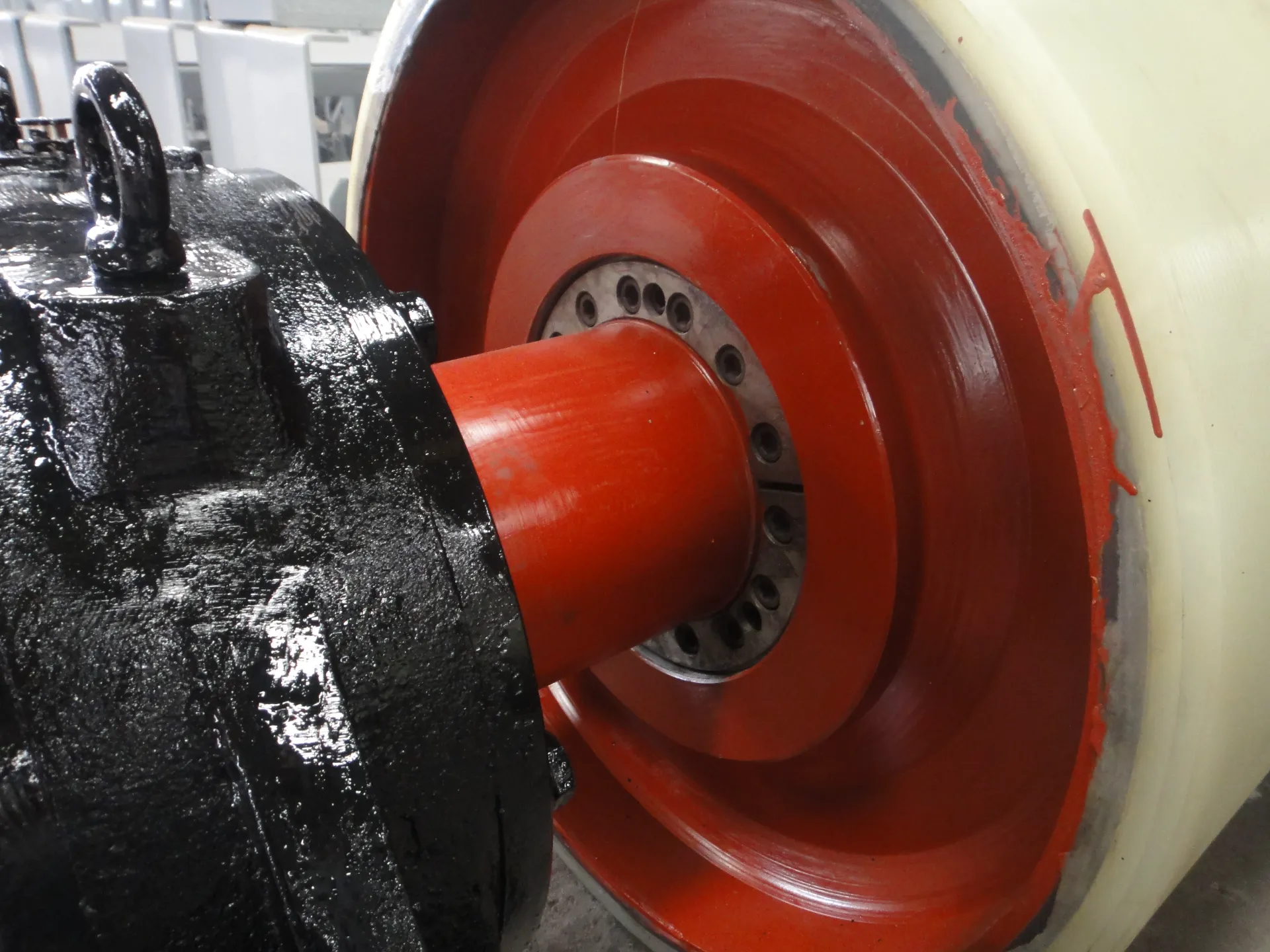

Polyurethane Pulley(Polyurethane Lagging Pulley)

When it comes to industrial applications that require durability and flexibility, polyurethane pulleys emerge as a premier choice. For those looking to enhance their machinery with high-quality components, understanding the benefits and unique characteristics of polyurethane pulleys is crucial. This article delves into the various aspects of polyurethane pulleys, offering insights from industry expertise and real-world experiences.

From an expert perspective, the selection of polyurethane pulleys is also aligned with sustainability goals. Polyurethane is more environmentally friendly compared to other synthetic materials, given its durability and reduced need for frequent replacements. Companies focused on green operations find polyurethane pulleys appealing due to their prolonged lifecycle and low environmental impact. Moreover, this commitment to sustainability does not compromise the operational efficacy, positioning polyurethane pulleys as the eco-conscious choice for forward-thinking enterprises. Even in the realm of safety, polyurethane pulleys demonstrate their benefits. Being inherently resistant to oils, greases, and various chemicals, these pulleys maintain their integrity where other materials might falter. This resistance reduces the risk of failures that could lead to machine breakdowns or workplace accidents. Consequently, polyurethane pulleys play a vital role in maintaining a safe working environment, a key consideration for firms prioritizing employee safety and well-being. In summary, the advantages of adopting polyurethane pulleys are multifaceted. Their durability, customizable features, noise-reduction capabilities, and environmental benefits combine to offer an unparalleled solution for various industrial needs. Companies seeking to improve their machinery's performance and reliability find in polyurethane pulleys not just a component but a strategic asset. With ongoing advancements in polyurethane technology, these pulleys will continue to set benchmarks in performance standards, underscoring their crucial role in the future of industrial applications. For businesses ready to make the shift, choosing polyurethane pulleys represents a forward-looking decision that aligns operational efficiency with responsible environmental practices. The investment in polyurethane technology is one that pays dividends through enhanced productivity, reduced maintenance, and a commitment to sustainability—a trifecta that defines successful modern industrial operation.

From an expert perspective, the selection of polyurethane pulleys is also aligned with sustainability goals. Polyurethane is more environmentally friendly compared to other synthetic materials, given its durability and reduced need for frequent replacements. Companies focused on green operations find polyurethane pulleys appealing due to their prolonged lifecycle and low environmental impact. Moreover, this commitment to sustainability does not compromise the operational efficacy, positioning polyurethane pulleys as the eco-conscious choice for forward-thinking enterprises. Even in the realm of safety, polyurethane pulleys demonstrate their benefits. Being inherently resistant to oils, greases, and various chemicals, these pulleys maintain their integrity where other materials might falter. This resistance reduces the risk of failures that could lead to machine breakdowns or workplace accidents. Consequently, polyurethane pulleys play a vital role in maintaining a safe working environment, a key consideration for firms prioritizing employee safety and well-being. In summary, the advantages of adopting polyurethane pulleys are multifaceted. Their durability, customizable features, noise-reduction capabilities, and environmental benefits combine to offer an unparalleled solution for various industrial needs. Companies seeking to improve their machinery's performance and reliability find in polyurethane pulleys not just a component but a strategic asset. With ongoing advancements in polyurethane technology, these pulleys will continue to set benchmarks in performance standards, underscoring their crucial role in the future of industrial applications. For businesses ready to make the shift, choosing polyurethane pulleys represents a forward-looking decision that aligns operational efficiency with responsible environmental practices. The investment in polyurethane technology is one that pays dividends through enhanced productivity, reduced maintenance, and a commitment to sustainability—a trifecta that defines successful modern industrial operation.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS