Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 10, 2025 11:33

Back to list

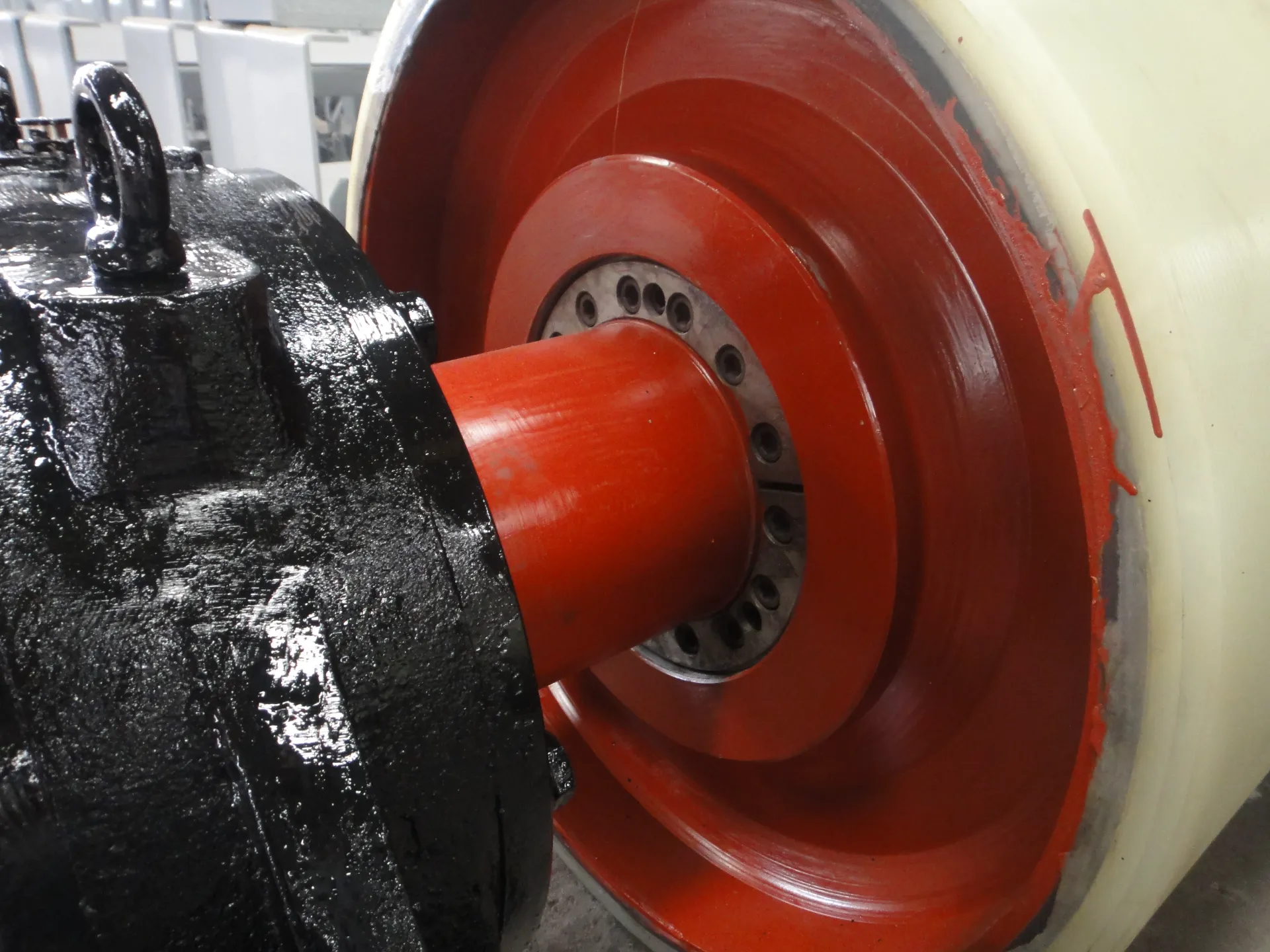

polyurethane pulley

Polyurethane pulleys have carved out a unique niche in the industrial market, offering unrivaled versatility and performance in various applications. These innovative components have rapidly gained favor across numerous industries, primarily due to their exceptional durability, flexibility, and ability to reduce noise and vibration. Our exploration into polyurethane pulleys is grounded in real-world experiences and backed by expert knowledge, ensuring that you gain comprehensive insights into this remarkable product.

Polyurethane's compatibility with various chemical exposures further diversifies its applications. Industries that handle harsh chemicals, like mining or chemical processing, benefit from polyurethane pulleys that resist degradation from contact with oils, solvents, and other reactive substances. This chemical resilience extends the operational capabilities of machinery, allowing them to function efficiently in otherwise corrosive environments. Expertise in manufacturing polyurethane pulleys involves a rigorous understanding of polymer science and engineering precision. Manufacturers leverage their technical acumen to produce pulleys that not only meet industry standards but exceed expectations in terms of performance and longevity. Companies at the forefront of this domain invest in cutting-edge production technologies and rigorous quality control measures to deliver products that instill confidence among their customers. For those in search of reliable, long-lasting pulley systems, the choice of supplier is as crucial as the material itself. Reputable providers of polyurethane pulleys are characterized by their transparency, consistently delivering on quality promises and providing expert guidance tailored to individual client needs. Such partnerships are grounded in a commitment to customer satisfaction, evidenced by generous warranties, comprehensive after-sales support, and a penchant for continuous innovation. In conclusion, polyurethane pulleys are an indispensable asset to industries that demand resilience, adaptability, and superior performance from their components. By harnessing the unique properties of polyurethane, these pulleys offer a sustainable, cost-effective solution that enhances the efficiency and safety of industrial operations. The informed choice of polyurethane pulleys reflects an understanding of material science, an appreciation of expert manufacturing, and a commitment to operational excellence. Those who invest in this technology position themselves at the cutting edge of industry innovation, reaping the benefits of superior product design and reliability.

Polyurethane's compatibility with various chemical exposures further diversifies its applications. Industries that handle harsh chemicals, like mining or chemical processing, benefit from polyurethane pulleys that resist degradation from contact with oils, solvents, and other reactive substances. This chemical resilience extends the operational capabilities of machinery, allowing them to function efficiently in otherwise corrosive environments. Expertise in manufacturing polyurethane pulleys involves a rigorous understanding of polymer science and engineering precision. Manufacturers leverage their technical acumen to produce pulleys that not only meet industry standards but exceed expectations in terms of performance and longevity. Companies at the forefront of this domain invest in cutting-edge production technologies and rigorous quality control measures to deliver products that instill confidence among their customers. For those in search of reliable, long-lasting pulley systems, the choice of supplier is as crucial as the material itself. Reputable providers of polyurethane pulleys are characterized by their transparency, consistently delivering on quality promises and providing expert guidance tailored to individual client needs. Such partnerships are grounded in a commitment to customer satisfaction, evidenced by generous warranties, comprehensive after-sales support, and a penchant for continuous innovation. In conclusion, polyurethane pulleys are an indispensable asset to industries that demand resilience, adaptability, and superior performance from their components. By harnessing the unique properties of polyurethane, these pulleys offer a sustainable, cost-effective solution that enhances the efficiency and safety of industrial operations. The informed choice of polyurethane pulleys reflects an understanding of material science, an appreciation of expert manufacturing, and a commitment to operational excellence. Those who invest in this technology position themselves at the cutting edge of industry innovation, reaping the benefits of superior product design and reliability.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS