Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 13, 2025 19:03

Back to list

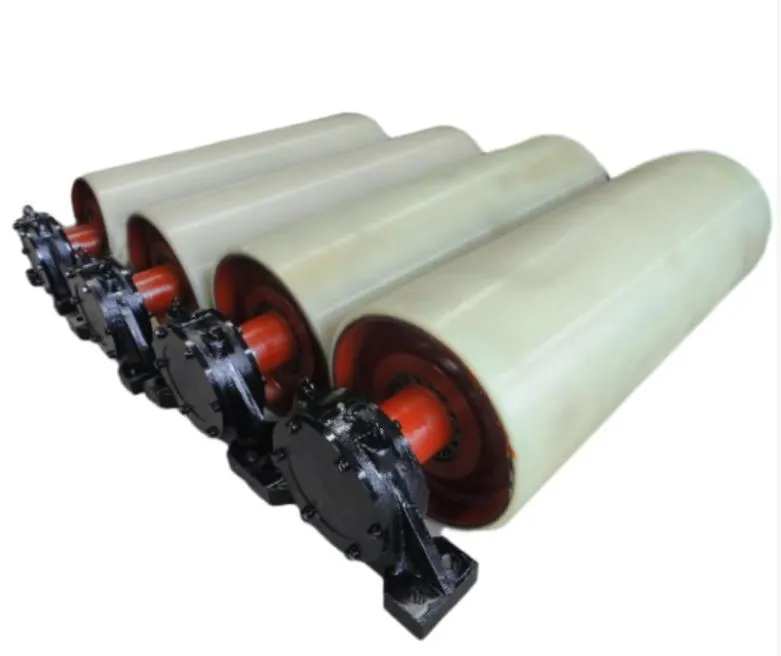

Polyurethane Roller

Polyurethane pipe rollers have redefined the landscape of industrial material handling and transportation systems. Their growing popularity is not just a passing trend but rooted in the undeniable advantages they offer over traditional metal or rubber rollers. This expert analysis explores the multifaceted benefits and applications of polyurethane pipe rollers, spearheaded by breakthrough engineering and material science advancements.

The lightweight nature of polyurethane also translates into logistical efficiencies. Ease of installation and handling reduces labor costs, and the reduced weight diminishes the strain on machinery, thereby extending the lifespan of motorized components. This weight advantage does not come at the expense of load-bearing capacity. On the contrary, polyurethane pipe rollers possess an impressive strength-to-weight ratio, enabling them to support significant loads while maintaining structural integrity. Eco-conscious organizations will appreciate polyurethane's environmental advantages. Polyurethane materials are potentially recyclable, and their longevity means less frequent replacements, contributing to waste reduction. The environmentally responsible choice of polyurethane pipe rollers aligns with sustainable business practices, garnering favor with both regulatory bodies and environmentally conscious clients. Innovation continues to drive the polyurethane market forward, with research and development focused on augmenting its capabilities. Whether these advancements concern enhanced temperature resistance or further improved load capacities, the future of polyurethane pipe rollers looks promising. This continuous improvement cycle ensures that companies employing these rollers remain on the cutting edge of efficiency and performance. In summary, polyurethane pipe rollers offer an unmatched combination of durability, flexibility, and performance. Their adoption across diverse industries underscores the material’s adaptability and strength. As industries evolve, those embracing polyurethane technologies will enjoy enhanced operational efficiencies, reduced maintenance costs, and a more sustainable footprint—testaments to polyurethane’s profound impact on industrial material handling. Such strategic benefits make polyurethane pipe rollers not just a choice but a pivotal investment in a company’s future operational success.

The lightweight nature of polyurethane also translates into logistical efficiencies. Ease of installation and handling reduces labor costs, and the reduced weight diminishes the strain on machinery, thereby extending the lifespan of motorized components. This weight advantage does not come at the expense of load-bearing capacity. On the contrary, polyurethane pipe rollers possess an impressive strength-to-weight ratio, enabling them to support significant loads while maintaining structural integrity. Eco-conscious organizations will appreciate polyurethane's environmental advantages. Polyurethane materials are potentially recyclable, and their longevity means less frequent replacements, contributing to waste reduction. The environmentally responsible choice of polyurethane pipe rollers aligns with sustainable business practices, garnering favor with both regulatory bodies and environmentally conscious clients. Innovation continues to drive the polyurethane market forward, with research and development focused on augmenting its capabilities. Whether these advancements concern enhanced temperature resistance or further improved load capacities, the future of polyurethane pipe rollers looks promising. This continuous improvement cycle ensures that companies employing these rollers remain on the cutting edge of efficiency and performance. In summary, polyurethane pipe rollers offer an unmatched combination of durability, flexibility, and performance. Their adoption across diverse industries underscores the material’s adaptability and strength. As industries evolve, those embracing polyurethane technologies will enjoy enhanced operational efficiencies, reduced maintenance costs, and a more sustainable footprint—testaments to polyurethane’s profound impact on industrial material handling. Such strategic benefits make polyurethane pipe rollers not just a choice but a pivotal investment in a company’s future operational success.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS