Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu polyurethane v roller

The Advantages of Polyurethane V Rollers in Modern Applications

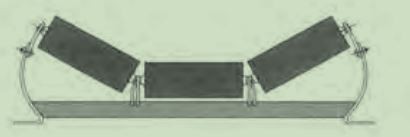

Polyurethane V rollers have emerged as a preferred choice in various industrial and commercial applications due to their exceptional properties. These rollers, designed with a V-shaped groove, are incredibly versatile and can be utilized in conveyor systems, material handling, and manufacturing processes. The benefits of using polyurethane for these rollers over traditional materials such as rubber or metal are numerous, making them increasingly popular in today's manufacturing environments.

The Advantages of Polyurethane V Rollers in Modern Applications

Furthermore, polyurethane's inherent flexibility and resilience provide excellent shock absorption and cushioning. This characteristic is essential in applications where heavy loads are transported, as it minimizes the risk of damaging both the products being moved and the equipment itself. The ability of polyurethane V rollers to handle sudden impacts and uneven surfaces allows for smooth operation, reducing the likelihood of disruptions in the production line.

polyurethane v roller

Another appealing feature of polyurethane V rollers is their chemical resistance. Unlike rubber, which can degrade when exposed to oils, solvents, or harsh chemicals, polyurethane maintains its integrity under such conditions. This makes it an ideal choice for industries that involve the handling of various materials, including food processing, pharmaceuticals, and chemical manufacturing. By using polyurethane, companies can ensure that their equipment remains operational and effective even in demanding environments.

The diversity of polyurethane formulations also allows for customization in hardness and other properties, making it possible to create V rollers tailored to specific application requirements. Depending on the intended use, manufacturers can adjust the hardness of the polyurethane to achieve the necessary grip, load-bearing capacity, and flexibility. This level of customization is a significant advantage for businesses looking to optimize their processes.

Lastly, polyurethane V rollers are environmentally friendly compared to some of their traditional counterparts. Many polyurethane products can be manufactured with recycled materials and are themselves recyclable, making them a more sustainable choice for companies looking to reduce their environmental impact. This aspect aligns with the growing trend toward sustainability in manufacturing, appealing to companies committed to eco-friendly practices.

In conclusion, polyurethane V rollers are an excellent choice for a wide range of applications due to their durability, flexibility, chemical resistance, and customization options. With their ability to enhance operational efficiency while minimizing maintenance costs, polyurethane V rollers represent a smart investment for businesses across various industries. As technology continues to evolve and the demand for reliable and effective materials increases, the adoption of polyurethane products will likely soar, solidifying their place in modern manufacturing and material handling.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025