Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 14, 2025 01:17

Back to list

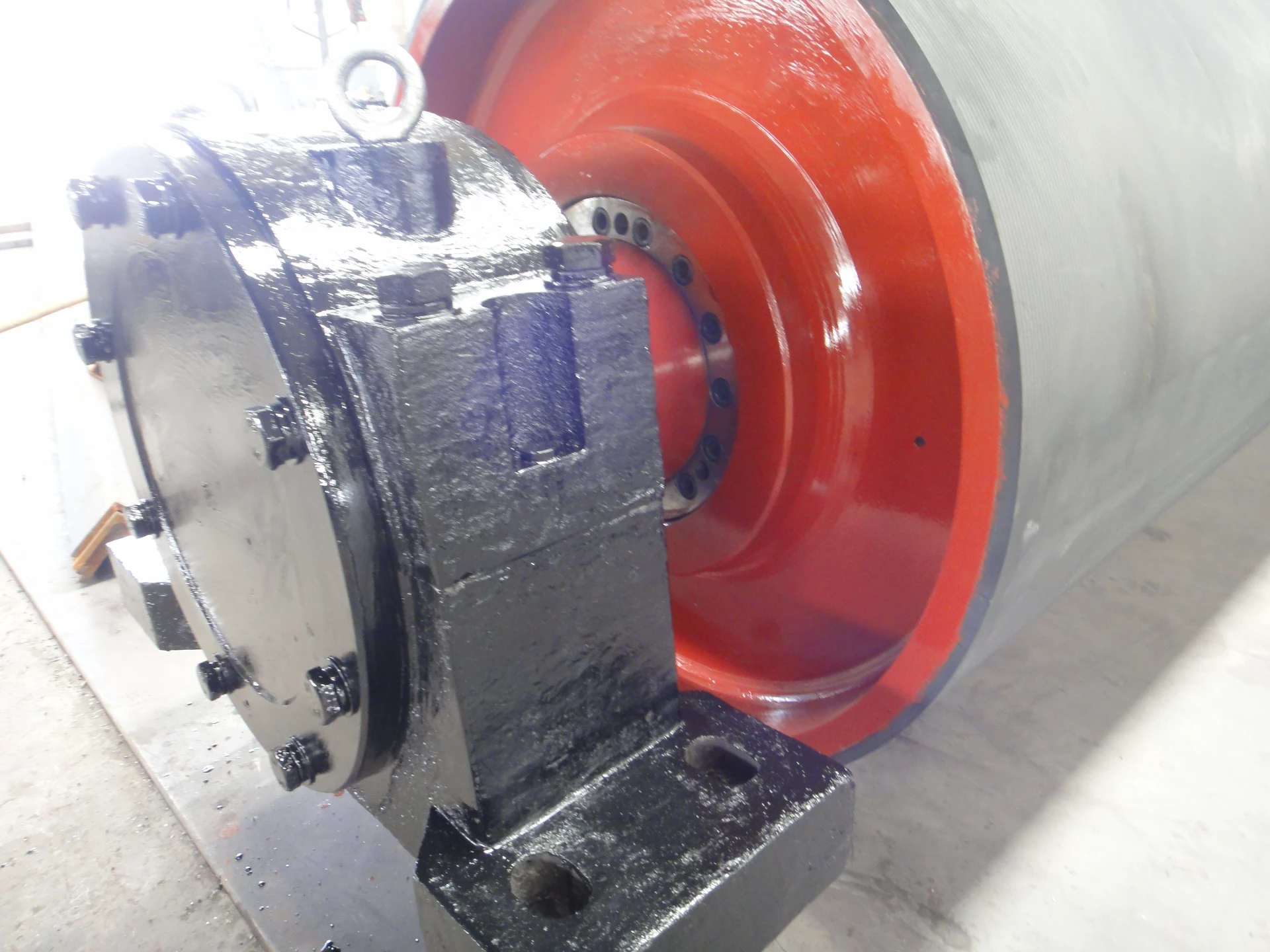

polyethylene roller

When considering components that enhance the efficiency and longevity of industrial machinery, polyethylene rollers emerge as a paramount choice. Known for their durability and versatility, these rollers are engineered to meet the rigorous demands of various industries. Herein, we'll delve into the intrinsic benefits, industrial applications, expert insights, and how to best implement polyethylene rollers for optimized operational results.

Authoritative bodies in material engineering and industrial design frequently endorse polyethylene rollers for their exceptional adaptability. Leading manufacturers emphasize that investing in quality polyethylene rollers yields returns in the form of increased productivity, reduced maintenance costs, and improved safety. Trustworthiness is rarely questioned given their robust performance across diverse environmental conditions. For businesses contemplating the integration of polyethylene rollers, the foremost step is a detailed assessment of their current machinery requirements. Consulting with a materials engineer can provide insights into the suitable type and density of polyethylene needed for specific applications. Incorporating expert input during the selection process ensures that the rollers not only meet operational demands but also enhance overall machine efficiency. Finally, to truly optimize the advantages of polyethylene rollers, companies must focus on staff training. Proper handling and installation practices extend the life of these components significantly. Technicians adept in managing polyethylene materials can identify minor issues before they escalate, ensuring the seamless operation of machinery. In conclusion, polyethylene rollers stand out as a pivotal component in modern industrial operations. Their versatility, coupled with cost efficiency and durability, make them a preferred choice across a spectrum of industries. By adopting these rollers, businesses not only secure operational excellence but also embark on a path towards sustainable industrial practices. Leveraging the unique properties of polyethylene, while adhering to expert recommendations, ensures that these rollers perform to their fullest potential, thereby affirming their place as indispensable assets in the industrial toolkit.

Authoritative bodies in material engineering and industrial design frequently endorse polyethylene rollers for their exceptional adaptability. Leading manufacturers emphasize that investing in quality polyethylene rollers yields returns in the form of increased productivity, reduced maintenance costs, and improved safety. Trustworthiness is rarely questioned given their robust performance across diverse environmental conditions. For businesses contemplating the integration of polyethylene rollers, the foremost step is a detailed assessment of their current machinery requirements. Consulting with a materials engineer can provide insights into the suitable type and density of polyethylene needed for specific applications. Incorporating expert input during the selection process ensures that the rollers not only meet operational demands but also enhance overall machine efficiency. Finally, to truly optimize the advantages of polyethylene rollers, companies must focus on staff training. Proper handling and installation practices extend the life of these components significantly. Technicians adept in managing polyethylene materials can identify minor issues before they escalate, ensuring the seamless operation of machinery. In conclusion, polyethylene rollers stand out as a pivotal component in modern industrial operations. Their versatility, coupled with cost efficiency and durability, make them a preferred choice across a spectrum of industries. By adopting these rollers, businesses not only secure operational excellence but also embark on a path towards sustainable industrial practices. Leveraging the unique properties of polyethylene, while adhering to expert recommendations, ensures that these rollers perform to their fullest potential, thereby affirming their place as indispensable assets in the industrial toolkit.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS