Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

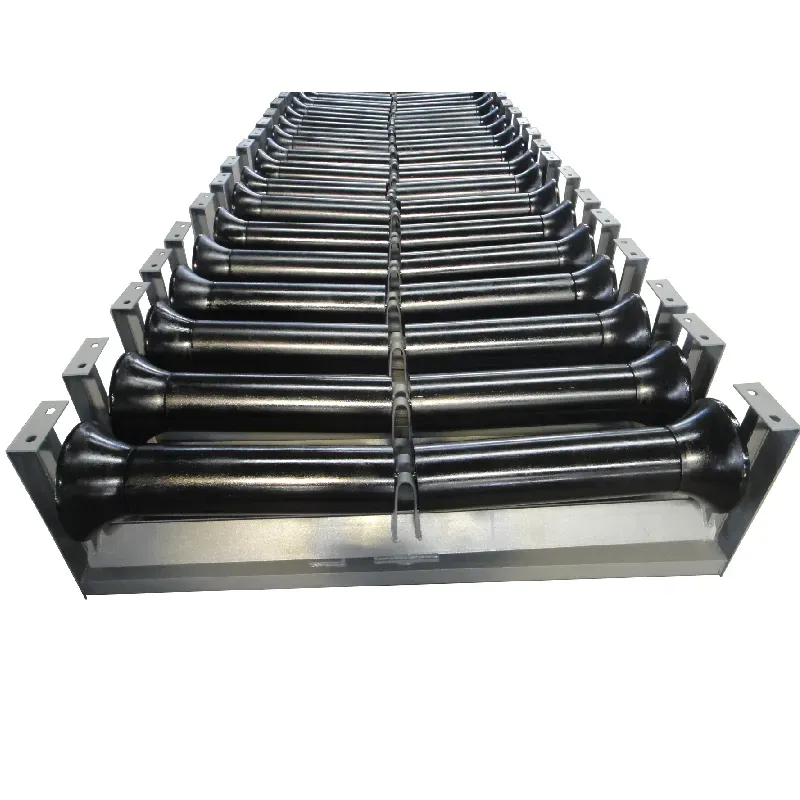

Zulu polyethylene roller

The Role of Polyethylene Rollers in Modern Industries

Polyethylene rollers have become an essential component in various industrial applications, owing to their durability, lightweight properties, and versatility. As industries evolve and seek innovative materials that enhance efficiency and productivity, polyethylene rollers emerge as a significant solution across multiple sectors. This article delves into the characteristics, applications, and advantages of polyethylene rollers in modern industries.

Understanding Polyethylene

Polyethylene, a thermoplastic polymer, is widely recognized for its strength, chemical resistance, and lightweight characteristics. It is available in different densities, with low-density polyethylene (LDPE) and high-density polyethylene (HDPE) being the most common types utilized in roller applications. LDPE is known for its flexibility and toughness, making it suitable for various applications where flexibility is crucial. On the other hand, HDPE offers enhanced rigidity and impact resistance, making it an ideal choice for more demanding environments.

Characteristics of Polyethylene Rollers

1. Durability One of the standout features of polyethylene rollers is their impressive durability. They can withstand harsh environmental conditions, including exposure to moisture, chemicals, and UV radiation, without degrading over time.

2. Lightweight Unlike traditional metal rollers, polyethylene rollers are significantly lighter, which makes them easier to handle and reduces the overall weight of machinery. This can lead to lower energy consumption during transportation and operation.

3. Corrosion Resistance Polyethylene is inherently resistant to corrosion, making these rollers ideal for use in environments where metal components would corrode rapidly. This resistance significantly prolongs the lifespan of the rollers and reduces maintenance costs.

4. Low Friction The smooth surface of polyethylene rollers provides low friction, which enhances the efficiency of operations, especially in conveyor systems. The reduction in friction translates to lower wear and tear on both the rollers and the systems they operate within.

Applications of Polyethylene Rollers

polyethylene roller

1. Conveyor Systems Polyethylene rollers are widely used in conveyor systems across various industries, from manufacturing to food processing. Their lightweight and durable nature facilitates smooth material handling, ensuring continuous operations.

2. Agriculture In agriculture, polyethylene rollers are often used in irrigation systems, seeders, and other farming equipment. Their resistance to chemical fertilizers and harsh weather conditions ensures longevity and reliability in the field.

3. Packaging The packaging industry benefits from polyethylene rollers in the production of packaging machinery. They help in the efficient movement of materials and products throughout the production line.

4. Sports Equipment Polyethylene rollers are also found in sports equipment, such as skateboards and inline skates, where their lightweight and low-friction properties enhance the overall performance and user experience.

Advantages of Using Polyethylene Rollers

The adoption of polyethylene rollers presents numerous advantages for industries looking to improve efficiency and reduce operational costs

- Cost-Effectiveness The longevity and low maintenance requirements of polyethylene rollers translate to cost savings over time, as businesses spend less on replacements and repairs. - Versatility Polyethylene rollers can be customized to meet specific requirements, including size, shape, and density, making them suitable for a wide range of applications.

- Sustainability Many polyethylene materials are recyclable, aligning with modern industries' sustainability goals and efforts to reduce environmental impact.

Conclusion

In summary, polyethylene rollers represent a significant advancement in roller technology, offering numerous benefits that cater to a variety of industrial applications. Their durability, lightweight properties, and resistance to corrosion make them an ideal choice for companies seeking to enhance their processes and reduce costs. As industries continue to evolve and prioritize efficiency, the role of polyethylene rollers is set to expand, driving innovation and productivity in the years to come. Whether in manufacturing, agriculture, or packaging, these versatile components are a testament to the ongoing evolution of materials used in modern industry.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025