Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu plastic pipe rollers

The Importance of Plastic Pipe Rollers in Modern Construction

In the ever-evolving field of construction and infrastructure development, the efficiency of material handling significantly impacts the overall productivity and safety of projects. One crucial component that has surfaced in recent years to aid in this regard is the plastic pipe roller. Designed specifically for facilitating the movement and installation of plastic pipes, these rollers have become indispensable tools in various applications, ranging from residential plumbing to large-scale industrial projects.

What Are Plastic Pipe Rollers?

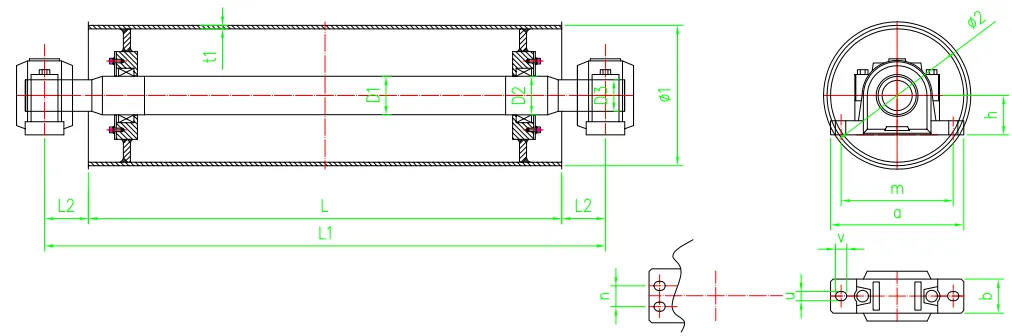

Plastic pipe rollers are specialized equipment designed to support and guide the movement of plastic pipes during transportation and installation. Made from durable materials, these rollers reduce friction and allow pipes to roll smoothly, minimizing the effort required to handle them. They are particularly useful when working with long lengths of piping, which can be cumbersome and challenging to maneuver without adequate support.

Benefits of Using Plastic Pipe Rollers

1. Enhanced Mobility The primary advantage of plastic pipe rollers is their ability to facilitate the movement of heavy pipes. By reducing the friction between the pipes and the ground, rollers allow workers to transport materials quickly and efficiently. This not only saves time but also reduces labor costs associated with manual handling.

plastic pipe rollers

2. Safety Lifting and moving heavy pipes manually can pose significant safety risks, including back injuries or accidents caused by misalignment and falling materials. Using plastic pipe rollers alleviates these concerns by enabling a safer, more ergonomic handling process. Workers can guide pipes into place without the strain of lifting, thus promoting a safer work environment.

3. Versatility Plastic pipe rollers come in various sizes and configurations to accommodate different pipe diameters and weights. Whether used for irrigation systems, drainage solutions, or gas pipelines, these rollers can be tailored to suit specific project requirements, making them a versatile choice for contractors.

4. Durability Made from high-quality plastics and engineered to withstand harsh environmental conditions, plastic pipe rollers are built to last. They resist chemicals and abrasions, ensuring that they maintain their functionality even in the most challenging settings.

5. Cost-Effectiveness While investing in professional-grade plastic pipe rollers may seem like an upfront cost, the long-term savings they provide can be substantial. By improving efficiency, reducing the risk of injury, and minimizing the likelihood of damaging materials, these tools can pay for themselves in time and labor saved.

Conclusion

In conclusion, plastic pipe rollers are a vital asset in modern construction, enhancing efficiency, safety, and durability during the handling of plastic pipes. As construction projects continue to grow in size and complexity, the use of such innovative equipment will undoubtedly play a key role in shaping the future of the industry. By investing in the right tools, contractors can streamline operations, safeguard their workforce, and ultimately deliver better results for clients. Whether on a small residential job or a vast industrial site, plastic pipe rollers are now an essential tool for every construction professional.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025