Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu plastic bearing housing

Understanding Plastic Bearing Housing Advantages and Applications

In the realm of engineering and manufacturing, the choice of materials plays a critical role in enhancing the performance and lifespan of various components. One such innovation that has gained substantial traction is the plastic bearing housing. Traditionally, bearing housings were predominantly made from metals and alloys, but the rise of synthetic materials has led to a paradigm shift. This article explores the concept of plastic bearing housing, its advantages, and its applications across different industries.

What is Plastic Bearing Housing?

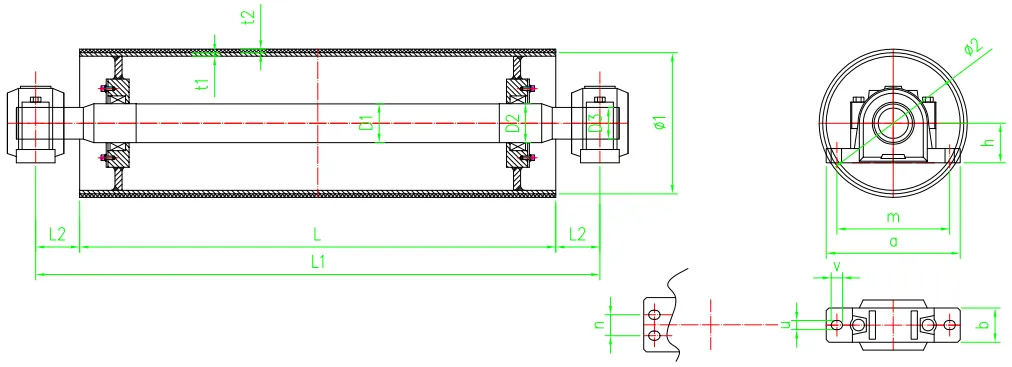

Bearing housings serve as the protective enclosures for bearings, which support rotating shafts and reduce friction in machinery. Plastic bearing housing is manufactured using high-performance polymers designed to withstand various operational stresses, including load, temperature fluctuations, and environmental factors. Common materials used for plastic housings include polyamide (nylon), polypropylene, and polyoxymethylene (POM), which are known for their durability and resistance to wear and corrosion.

Advantages of Plastic Bearing Housing

1. Lightweight Design One of the most significant advantages of plastic bearing housings is their lightweight nature. Compared to traditional metal housings, plastic is significantly lighter, leading to reduced overall machinery weight. This reduction can enhance energy efficiency during operation and decrease transport costs.

2. Corrosion Resistance Plastic materials are inherently resistant to corrosion, making them an ideal choice for environments exposed to moisture, chemicals, or harsh weather conditions. While metal housings may rust or corrode over time, plastic housings maintain their structural integrity, thereby extending the lifespan of the bearing assembly.

3. Lower Manufacturing Costs Plastic components can often be produced at a lower cost due to the efficiency of modern injection molding techniques. This cost-effectiveness translates to savings for manufacturers, who can allocate their resources more efficiently.

4. Noise and Vibration Dampening Plastic bearings have excellent noise and vibration dampening qualities. This feature can lead to quieter machinery operation, which is particularly beneficial in environments where noise control is essential, such as in residential areas or sensitive industrial settings.

5. Thermal and Electrical Insulation Many plastic materials provide good thermal and electrical insulation properties. This ensures that the bearings remain safe from electrical interference and helps manage temperature fluctuations, further protecting the equipment.

plastic bearing housing

6. Design Flexibility The versatility of plastics allows for complex geometric shapes and designs that are difficult to achieve with metals. This flexibility can lead to customized solutions tailored to specific applications or unique machinery requirements.

Applications of Plastic Bearing Housing

The applications of plastic bearing housings are widespread, encompassing various industries, including

- Agriculture Plastic bearing housings are utilized in agricultural machinery such as harvesters and irrigation systems, where exposure to harsh chemicals and the need for corrosion resistance are critical.

- Food and Beverage In food processing and packaging equipment, hygiene is paramount. Plastic housings are favored due to their non-corrosive properties and ease of cleaning, which align with stringent health and safety regulations.

- Automotive The automotive industry is increasingly adopting plastic components to reduce weight and improve fuel efficiency. Plastic bearing housings are commonly found in electric motors, pumps, and other automotive applications.

- Electronics In the electronics sector, plastic bearing housings are employed in devices such as computer fans and hard drives, where low weight and effective insulation are necessary.

- Medical Devices The medical field relies on bearings for various applications, including surgical instruments and diagnostic equipment. Plastic housing ensures safety and sterility, vital in healthcare settings.

Conclusion

Plastic bearing housings represent a significant advancement in engineering materials, providing numerous benefits that enhance machinery performance and longevity. Their lightweight nature, resistance to corrosion, and design flexibility make them suitable for a diverse range of applications. As industries continue to evolve and seek efficient, cost-effective solutions, the adoption of plastic bearing housings is likely to increase, driving further innovation in material science. With their proven advantages, it is clear that plastic bearing housings are not just a replacement for traditional materials, but a vital component in the future of engineering and manufacturing.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025