Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

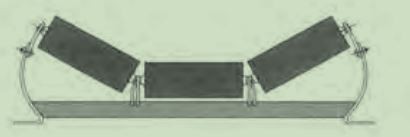

Zulu High-Quality Plastic Rollers for Various Applications

The Versatility and Utility of Plastic Rollers

Plastic rollers are an often-overlooked yet incredibly versatile tool used across various industries, from manufacturing and printing to packaging and construction. Their lightweight, durable, and corrosion-resistant properties make them ideal for numerous applications, allowing for efficient operations while minimizing maintenance costs.

One of the primary advantages of plastic rollers is their ability to reduce friction. In conveyor systems, for instance, plastic rollers can facilitate smooth movement of goods, minimizing wear and tear on both the rollers and the transported items. This characteristic is particularly important in environments where heavy loads are common. The low coefficient of friction inherent to plastic materials allows for easy movement, enhancing productivity and ensuring that operations run seamlessly.

In addition to their functional benefits, plastic rollers come in a variety of shapes, sizes, and designs, making them suitable for specialized applications. For example, in the printing industry, rollers are used to transfer ink onto substrates. The choice of material can significantly affect the quality of the print and the efficiency of the printing process. Plastic rollers can be engineered to be non-stick, ensuring even distribution of ink and preventing clogging, which can lead to costly downtime.

plastic roller

Another area where plastic rollers excel is in packaging. They are commonly utilized in the production lines of packaging machines, where they assist in the process of aligning and transporting products. The resistance to chemicals found in certain plastic materials makes them preferable in environments where exposure to various substances is frequent. The use of plastic rollers in packaging not only increases efficiency but also enhances the overall safety of handling products.

In construction and DIY projects, plastic rollers are invaluable tools. They are used in applying paint, adhesives, and other materials evenly across surfaces. Their design allows for exceptional maneuverability, which is crucial when working in intricate spaces. Additionally, plastic rollers can be easily cleaned, making them a cost-effective choice for contractors who require reliable tools that can withstand repeated use.

Furthermore, the environmental aspect of plastic rollers cannot be overlooked. Many manufacturers are now focusing on sustainability, producing rollers made from recycled plastic materials or bioplastics. This shift not only reduces the environmental impact associated with plastic waste but also caters to the increasing consumer demand for eco-friendly products.

In summary, plastic rollers are indispensable tools across various sectors, offering a blend of efficiency, durability, and adaptability. Their capability to reduce friction makes them particularly advantageous in transportation and manufacturing processes. Moreover, advancements in materials used for plastic rollers are paving the way for more sustainable options that align with global efforts to minimize environmental impact. As industries continue to evolve, the role of plastic rollers will undoubtedly expand, reinforcing their position as a critical component in modern operational strategies. With ongoing innovations and increasing awareness of sustainability, the future of plastic rollers looks promising, ensuring their relevance for years to come.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025