Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Durable Plastic Bearing Housing for High Performance Applications

The Benefits and Applications of Plastic Bearing Housings

In the world of engineering and manufacturing, the choice of materials plays a crucial role in the performance and longevity of mechanical components. Among these, plastic bearing housings have emerged as an innovative solution, providing several advantages over traditional metal housings. This article explores the benefits, applications, and considerations surrounding plastic bearing housings.

Advantages of Plastic Bearing Housings

One of the most significant advantages of plastic bearing housings is their lightweight nature. Compared to metal alternatives, plastic housings can significantly reduce the overall weight of machinery and equipment. This reduction in weight is particularly beneficial in industries such as aerospace and automotive, where fuel efficiency and performance are paramount.

Another advantage is the corrosion resistance that plastic materials inherently provide. Metals can corrode when exposed to moisture, chemicals, or harsh environments, leading to premature wear and failure. Plastic bearing housings, on the other hand, can withstand these adverse conditions without deterioration, making them ideal for applications in chemical processing, food production, and outdoor machinery.

Plastic housings also offer excellent insulation properties. In electrical applications, this characteristic can prevent short circuits and protect sensitive components from electrical interference. Moreover, plastics can operate effectively across various temperature ranges, maintaining structural integrity in both low and high temperatures.

Applications in Various Industries

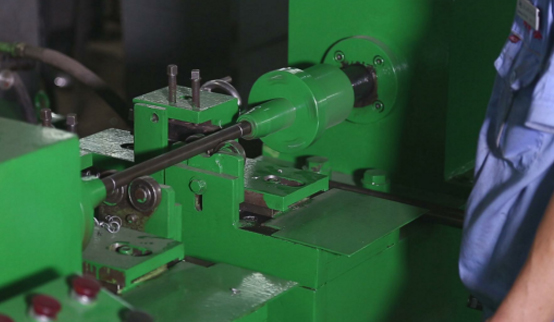

plastic bearing housing

Plastic bearing housings are utilized in a diverse array of industries. In the automotive sector, lightweight components contribute to improved fuel efficiency and performance while reducing wear on engine and transmission parts. In the food and beverage industry, the non-corrosive nature of plastics makes them suitable for use in environments where sanitation is critical, such as conveyor systems that transport food products.

Furthermore, plastic bearing housings find their applications in medical devices, where hygiene and material compatibility with bodily fluids are essential. They are also highly regarded in the manufacturing of household appliances, where low noise operation and durability are of utmost importance.

Considerations and Future Trends

While plastic bearing housings provide numerous benefits, it is crucial to consider the specific requirements of each application. Factors such as load capacity, operating environment, and potential exposure to specific chemicals must be assessed to ensure that the selected plastic material is suitable.

As technology advances, the development of high-performance plastics continues to expand the potential applications of plastic bearing housings. Innovations in material science may lead to composites that combine the lightweight and corrosion-resistant properties of plastics with the strength of metals, offering even greater performance.

In conclusion, plastic bearing housings present an excellent alternative to traditional metal options, boasting advantages such as reduced weight, corrosion resistance, and excellent electrical insulative properties. Their applicability across various industries underscores their versatility and potential for the future. As engineers and manufacturers increasingly prioritize sustainability and efficiency, the role of plastic bearing housings is likely to grow, paving the way for enhanced designs and improved performance in mechanized systems.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025