Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Optimizing Idler Selection for Enhanced Performance and Efficiency in Operations

The Importance of Picking Idler in Modern Machinery

In the ever-evolving landscape of modern machinery, the efficiency and performance of various components play a pivotal role in determining the overall functionality of machines. Among these components, the picking idler stands out as a significant element that warrants attention. Often overlooked, the picking idler is crucial in applications such as conveyor systems, textile machinery, and various automated processes. This article delves into the importance of picking idlers, their function, and the impact they have on modern industrial operations.

Understanding the Picking Idler

A picking idler is a type of rotating component that supports and guides the movement of materials within a machine. It is designed to enhance the efficiency of the picking process by allowing the smooth transfer of items from one conveyor to another or within a production line. Idlers can be found in a variety of shapes and sizes, often tailored to the specific requirements of the machinery they are integrated with. The picking idler is typically engineered to reduce friction and wear, ensuring that the materials can be moved seamlessly without causing damage or delays.

The Role of Picking Idlers in Efficiency

The primary function of the picking idler is to facilitate the smooth movement of materials. In a conveyor system, for instance, the idler serves as a support point that minimizes resistance, thus allowing the motor to operate more efficiently. By reducing friction, the picking idler ensures that energy is conserved, leading to lower operational costs. Moreover, the proper use of idlers can enhance the lifespan of both the machinery and the items being transported, as they prevent unnecessary wear and tear.

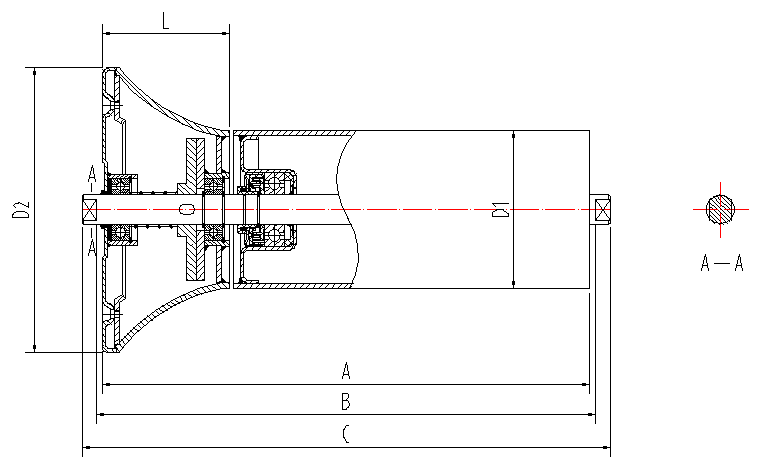

picking idler

In sectors such as textiles, the picking idler is instrumental in guiding fabrics through different stages of production. In these applications, precision is key, and the idler provides the necessary control to prevent jamming or misalignment of materials. This precision not only enhances the quality of the finished product but also reduces waste, making operations more sustainable.

The Innovation Behind Picking Idlers

As industries continue to innovate, so too has the technology behind picking idlers. Modern designs often incorporate advanced materials and manufacturing techniques that enhance durability and performance. For example, many picking idlers are now made from composite materials that resist wear and corrosion, providing a longer service life. Additionally, advancements in bearing technology have led to smoother operation with fewer maintenance requirements.

Furthermore, the integration of smart technology into picking idlers is revolutionizing their use. With sensors and IoT capabilities, manufacturers can monitor the performance of these components in real-time. This data-driven approach allows for proactive maintenance, ensuring that potential issues are addressed before they escalate into costly failures. Moreover, real-time monitoring can optimize the operation of the picking idler, further enhancing efficiency.

Conclusion

In conclusion, the picking idler may seem like a small component, but its importance in modern machinery cannot be overstated. By facilitating the smooth movement of materials and enhancing operational efficiency, picking idlers play a critical role in various industries. As technology continues to advance, the innovations in idler design and function will further improve productivity and sustainability across sectors. In an age where efficiency is paramount, paying attention to the role of components like the picking idler is essential for organizations looking to maintain a competitive edge in the marketplace. Investing in high-quality picking idlers, along with regular maintenance and monitoring, will undoubtedly yield significant returns in performance and cost-effectiveness. As industries strive to improve their processes, the humble picking idler will continue to be a key player in achieving these goals.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025