Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu picking idler

Understanding the Importance of Picking Idlers in Conveyor Systems

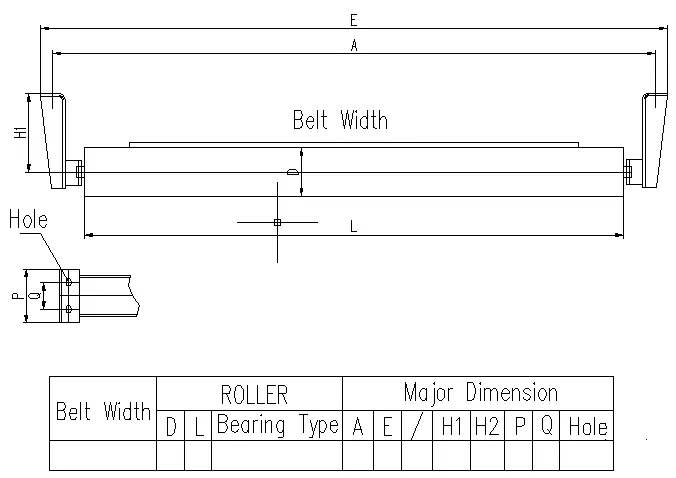

In modern logistics and manufacturing, conveyor systems play a crucial role in facilitating the smooth movement of materials. Among the various components that comprise these systems, picking idlers are often overlooked but are vital for optimizing operational efficiency. Picking idlers are specifically designed rollers that support the movement of products on conveyor lines, particularly in picking operations where items need to be easily accessed and sorted by workers or automated systems.

The primary function of picking idlers is to reduce friction and facilitate smooth movement, ensuring that items are transported swiftly and safely. They are strategically positioned along the conveyor belt to support the weight of the items being moved, preventing them from sagging or becoming misaligned. This is especially important in warehouses where workers frequently pick items from the conveyor for packing or sorting, as improper alignment can lead to delays and increased risk of accidents.

One of the key advantages of using picking idlers is their ability to adapt to various types of materials and products. Whether dealing with lightweight boxes or heavier pallets, picking idlers can be custom-designed to handle different weights and dimensions. This versatility not only enhances the overall functionality of the conveyor system but also extends its lifespan by minimizing wear and tear.

picking idler

Furthermore, picking idlers contribute to ergonomic efficiency in picking operations. When items are positioned at the optimal height and angle, workers can reach them comfortably without straining, which significantly reduces the likelihood of workplace injuries. Properly designed picking idlers can thus improve the workflow and productivity of warehouse staff, leading to increased operational efficiency.

Maintenance is another crucial aspect of picking idlers. Regular inspection and maintenance can prevent malfunctions that might result from debris accumulation or wear on the rollers. A solid maintenance plan ensures that picking idlers remain in optimal condition, ultimately preventing costly downtime and loss of productivity.

Incorporating advanced technologies into the design of picking idlers is also on the rise. Smart sensors can be integrated into the idler system to monitor the movement of items, providing real-time data that helps in optimizing pick rates and identifying potential bottlenecks. This level of automation and monitoring allows businesses to have better control over their logistics operations.

In conclusion, picking idlers are essential components of conveyor systems that enhance both efficiency and safety in picking operations. Their role in smoothing the transportation of products, promoting ergonomic practices, and supporting maintenance efforts cannot be overstated. As industries continue to evolve, the importance of investing in high-quality picking idlers will only grow, ensuring that businesses can meet the demands of modern logistics while maintaining optimal productivity levels.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025