Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu neoprene idler rollers

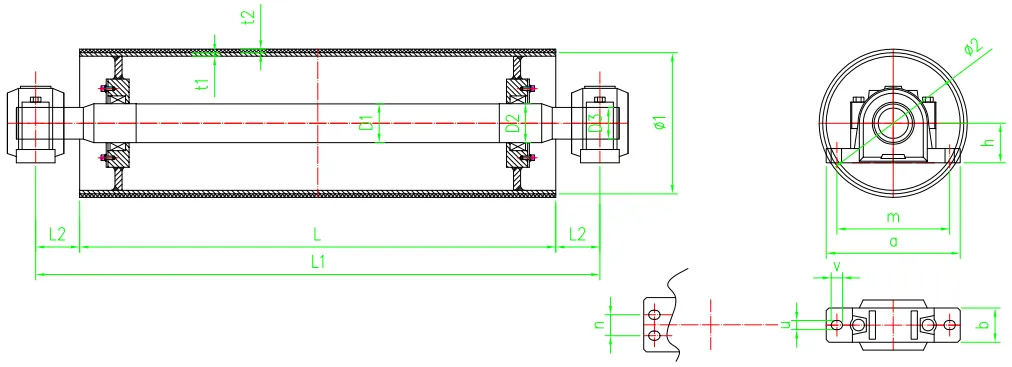

Understanding Neoprene Idler Rollers A Key Component in Material Handling

Neoprene idler rollers are essential components in various industrial applications, particularly in material handling systems. These rollers, made from neoprene—a synthetic rubber known for its resilience and versatility—play a critical role in ensuring the smooth operation of conveyor belts and other machinery. Their unique properties make them particularly suitable for environments that demand durability and resistance to wear and tear.

One of the primary advantages of neoprene idler rollers is their excellent resistance to a range of environmental factors. Neoprene is tolerant of heat, oil, chemicals, and ozone, making the rollers less prone to degradation in harsh conditions. This increased durability extends the lifespan of the rollers, reducing the frequency of replacements and thereby minimizing maintenance costs for businesses.

In addition to their strength, neoprene idler rollers provide significant friction control, which is vital for maintaining the efficiency of conveyor systems

. The unique surface characteristics of neoprene allow these rollers to grip materials effectively, preventing slippage and ensuring that products move smoothly along the assembly line. This feature is particularly important in industries such as food processing, manufacturing, and mining, where material handling efficiency directly impacts productivity and profitability.neoprene idler rollers

Moreover, neoprene idler rollers come in a variety of sizes and configurations, making them highly adaptable to different applications. Whether it's transporting lightweight packages or heavy industrial materials, these rollers can be customized to meet specific operational needs. This flexibility allows businesses to optimize their production processes and enhance overall efficiency.

Another noteworthy factor is the environmental benefits associated with neoprene. As industries increasingly prioritize sustainability, using neoprene rollers made from recycled materials is becoming more common. This approach not only helps in reducing environmental impact but also appeals to consumers who are conscious of sustainability practices.

In conclusion, neoprene idler rollers are a vital part of modern material handling systems. Their durability, resistance to environmental factors, and effective performance in friction control make them indispensable in various industrial applications. As technology progresses and industries evolve, the role of neoprene idler rollers will likely expand, continuing to support efficient and sustainable operations. Businesses aiming to enhance their material handling processes should consider the benefits of integrating neoprene idler rollers into their systems.