Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 18, 2025 11:29

Back to list

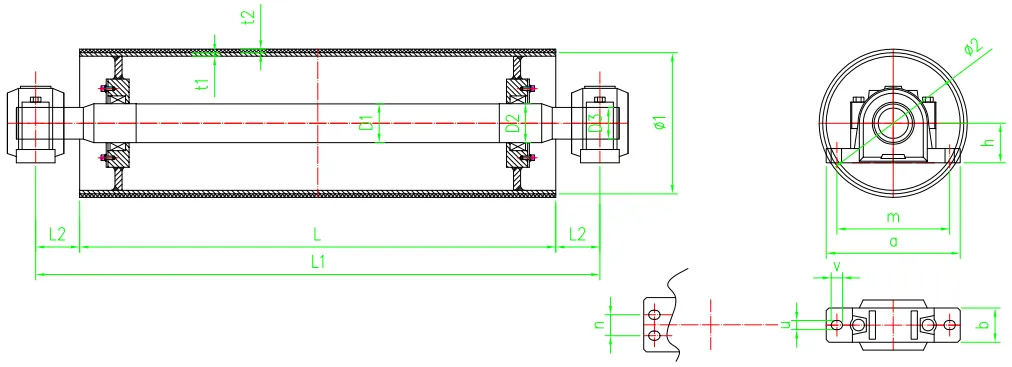

Polyurethane Pulley(Polyurethane Lagging Pulley)

Motorized drum pulleys, a critical component in conveyor systems, have revolutionized various industries by introducing efficiency and reliability. Over the years, these innovative devices have seen significant technological advancements, making them indispensable in operations that require seamless material handling. With decades of evolution in design and functionality, motorized drum pulleys now offer enhanced features that underscore their pivotal role in modern industrial applications.

The customization capabilities of motorized drum pulleys further supplement their appeal in specialized applications. Manufacturers increasingly offer tailored solutions to meet specific operational demands, whether it’s for extreme temperatures, unique material characteristics, or specific speed requirements. This customization ensures that each motorized drum pulley caters precisely to the needs of its application, enhancing the overall productivity of the system. Advanced control systems integrated into modern motorized drum pulleys also enhance their efficiency. With the introduction of smart sensors and IoT connectivity, operators can now monitor the performance of their conveyor systems in real time, preemptively addressing issues before they escalate. This capability not only prolongs the life of the equipment but also optimizes the operational workflow, contributing to a significant uptick in productivity. However, the adoption of motorized drum pulleys is not devoid of challenges. The initial investment and installation complexity could be seen as deterrents. Yet, when examined through the lens of long-term benefits such as reduced maintenance costs, enhanced reliability, and energy savings, the return on investment is evident. With technology consistently advancing, these challenges are gradually being addressed, making motorized drum pulleys more accessible and easier to integrate into existing systems. Ultimately, the evolution of motorized drum pulleys symbolizes the broader trend towards automation and integration in industrial processes. Their ability to encapsulate functionality, durability, and efficiency in a compact design positions them as crucial components in diverse sectors. As industries continue to pursue efficiency and sustainability, motorized drum pulleys stand out as transformative elements in the conveyor belt landscape, continually adapting to meet the futuristic demands of industry 4.0. For industries pondering the incorporation of motorized drum pulleys, understanding these dynamic changes and technological advancements is crucial. Engaging with experts who have an in-depth understanding of specific industry needs and the associated system requirements can provide invaluable insights. This partnership ensures that the solutions implemented not only meet current demands but are also scalable to future challenges, embedding trust and fostering continuous innovation.

The customization capabilities of motorized drum pulleys further supplement their appeal in specialized applications. Manufacturers increasingly offer tailored solutions to meet specific operational demands, whether it’s for extreme temperatures, unique material characteristics, or specific speed requirements. This customization ensures that each motorized drum pulley caters precisely to the needs of its application, enhancing the overall productivity of the system. Advanced control systems integrated into modern motorized drum pulleys also enhance their efficiency. With the introduction of smart sensors and IoT connectivity, operators can now monitor the performance of their conveyor systems in real time, preemptively addressing issues before they escalate. This capability not only prolongs the life of the equipment but also optimizes the operational workflow, contributing to a significant uptick in productivity. However, the adoption of motorized drum pulleys is not devoid of challenges. The initial investment and installation complexity could be seen as deterrents. Yet, when examined through the lens of long-term benefits such as reduced maintenance costs, enhanced reliability, and energy savings, the return on investment is evident. With technology consistently advancing, these challenges are gradually being addressed, making motorized drum pulleys more accessible and easier to integrate into existing systems. Ultimately, the evolution of motorized drum pulleys symbolizes the broader trend towards automation and integration in industrial processes. Their ability to encapsulate functionality, durability, and efficiency in a compact design positions them as crucial components in diverse sectors. As industries continue to pursue efficiency and sustainability, motorized drum pulleys stand out as transformative elements in the conveyor belt landscape, continually adapting to meet the futuristic demands of industry 4.0. For industries pondering the incorporation of motorized drum pulleys, understanding these dynamic changes and technological advancements is crucial. Engaging with experts who have an in-depth understanding of specific industry needs and the associated system requirements can provide invaluable insights. This partnership ensures that the solutions implemented not only meet current demands but are also scalable to future challenges, embedding trust and fostering continuous innovation.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS