Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu mine duty wing pulley

Understanding Mine Duty Wing Pulley An Essential Component in Mining Operations

In the world of mining, especially in resource extraction industries, the efficiency and safety of operations are paramount. One critical component that significantly contributes to these factors is the mine duty wing pulley. This article will explore what mine duty wing pulleys are, their functionalities, advantages, and their impact on the mining industry.

What is a Mine Duty Wing Pulley?

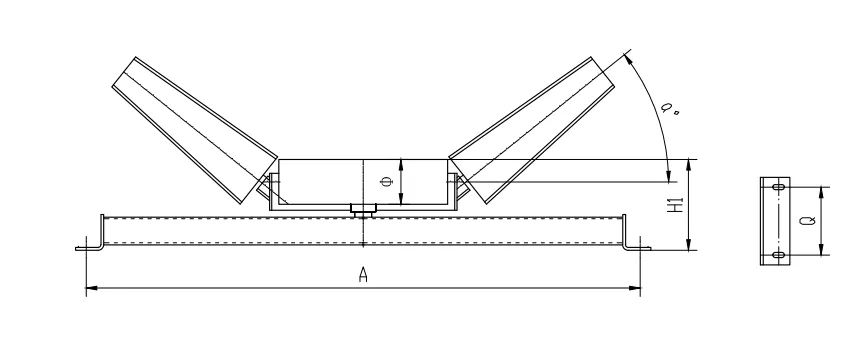

A mine duty wing pulley is a specialized component used within conveyor belt systems, which are integral to transporting materials in mining operations. These pulleys are designed to withstand the harsh conditions typical in mining environments, including extreme weights, dust, and vibrations. The wing part of the pulley refers to its unique design, which typically features protruding flanges that help in maintaining belt alignment and reducing slippage during operation.

Functions of Mine Duty Wing Pulleys

The primary function of mine duty wing pulleys is to support and stabilize conveyor belts as they transport materials such as coal, ore, and aggregates. They achieve this through several key functions

1. Belt Tracking The design of wing pulleys helps keep the conveyor belt properly aligned, which is vital to prevent material spillages and avoid unnecessary wear on the belt.

2. Load Distribution Wing pulleys are engineered to distribute loads evenly across the conveyor belt, enhancing the system's overall efficiency and longevity.

4. Enhanced Durability Mine duty wing pulleys are constructed from robust materials to withstand harsh operational conditions, ensuring they have a longer service life compared to standard pulleys.

Advantages of Mine Duty Wing Pulleys

mine duty wing pulley

Incorporating mine duty wing pulleys into mining operations offers numerous advantages

- Increased Efficiency By ensuring proper belt alignment and reducing slip, these pulleys can significantly increase the efficiency of material transport, which is crucial for maintaining productivity in mining operations.

- Cost Savings The durability of mine duty wing pulleys leads to less frequent replacements and lower maintenance costs over time. This translates into overall cost savings for mining companies.

- Safety Improvements By maintaining proper belt operation and decreasing the risk of material spills, mine duty wing pulleys contribute to a safer working environment for miners.

- Versatility These pulleys can be utilized in various applications, making them suitable for different types of mining operations, whether surface or underground.

The Impact on Mining Operations

The role of mine duty wing pulleys in mining operations cannot be overstated. They are a small but vital component in the larger conveyor belt system, which is often the backbone of mining logistics. With the ongoing demand for more efficiency and safer operations in the mining industry, the importance of reliable components like mine duty wing pulleys will continue to grow.

Additionally, as mining companies increasingly focus on sustainability and reducing their environmental impact, efficient material handling systems, aided by effective components like wing pulleys, will play an essential role. The ability to transport materials without excessive leakage not only conserves resources but also minimizes the ecological footprint of mining activities.

Conclusion

In summary, mine duty wing pulleys are an essential component of effective and efficient mining operations. Their ability to improve belt tracking, reduce wear, and enhance durability makes them a critical element that contributes to the overall success of mining activities. As technology advances and the mining industry evolves, the importance of designing and implementing high-quality components like mine duty wing pulleys will remain a focal point for achieving operational excellence and safety. For mining companies looking to optimize their systems, investing in quality mine duty wing pulleys may very well be a step toward achieving those goals.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025