Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu lagging rubber

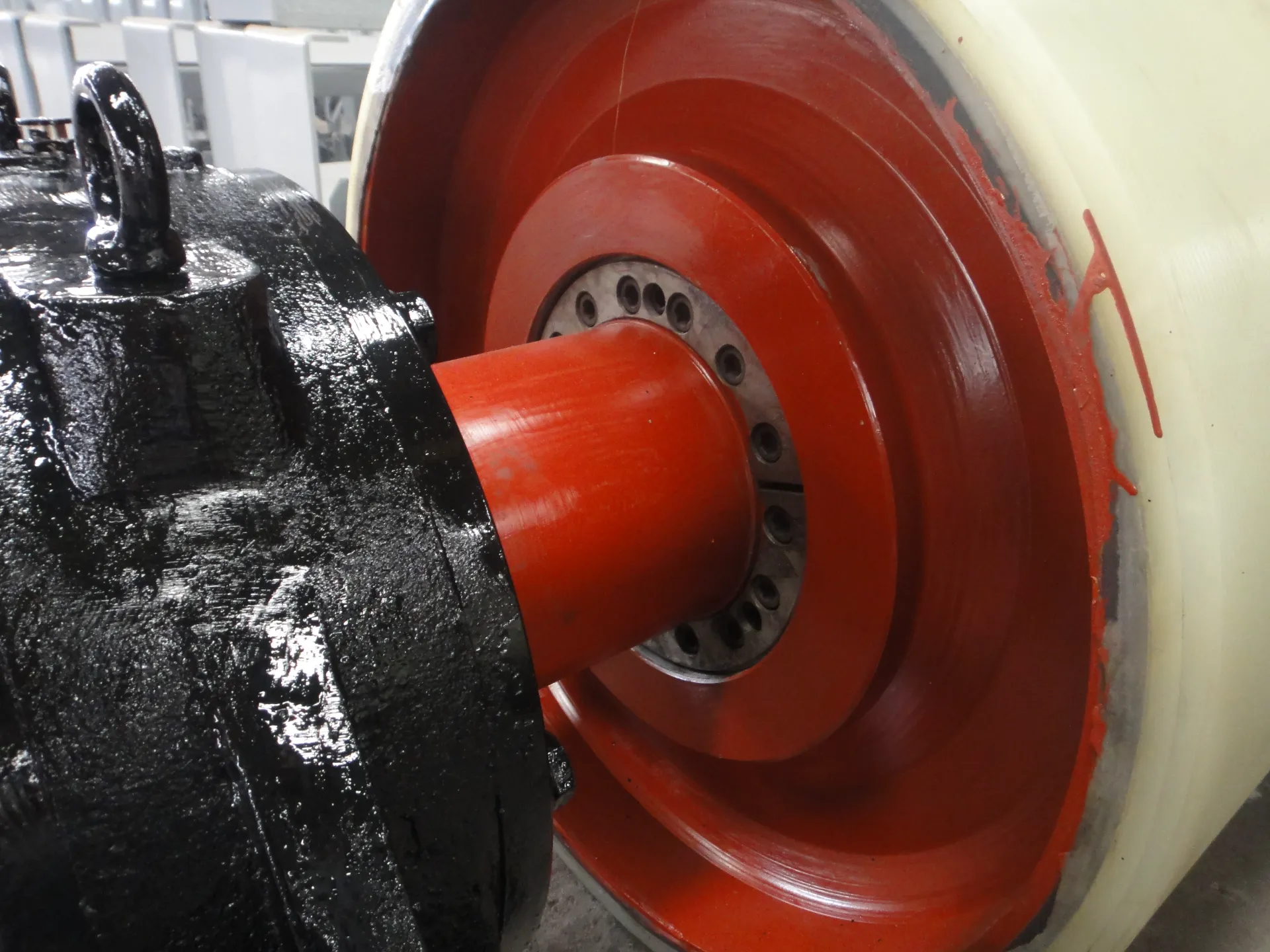

The Role of Lagging Rubber in Industrial Applications

Lagging rubber is a crucial material in various industrial applications, primarily known for its protective and anti-friction characteristics. This specialized rubber is often used in the mining, construction, and manufacturing industries, where heavy machinery operates under demanding conditions. Understanding the properties and advantages of lagging rubber can help industries enhance operational efficiency and safety.

One of the primary applications of lagging rubber is in the protection of conveyor belts. In industries that rely heavily on conveyor systems, such as mining and bulk material handling, the wear and tear on belts can lead to significant downtime and maintenance costs. Lagging rubber is applied to the pulleys and conveyor rollers, creating a tough surface that improves traction and reduces slippage. This increase in grip ensures a reliable transfer of materials, minimizing the risk of disruptions in the production process.

Furthermore, lagging rubber provides excellent resistance to abrasion and impacts. In environments where heavy materials are frequently transported, the conveyor components face continuous stress. The added layer of lagging rubber absorbs shocks, thereby prolonging the life of these components. This durability is particularly beneficial for industries working with harsh materials, as it reduces the need for frequent replacements and repairs, ultimately leading to cost savings.

Another significant advantage of lagging rubber is its ability to prevent wear on equipment

. In applications such as crushers and mills, the constant motion and pressure can lead to the degradation of machinery over time. By utilizing lagging rubber, companies can effectively shield their equipment, reducing maintenance needs and ensuring smoother operations. This protective measure is vital not only for extending machinery life but also for maintaining the overall efficiency of the production processes.lagging rubber

Moreover, lagging rubber is also utilized in the manufacturing of industrial clutches and brakes. The friction generated by these components is critical for their performance, and the right type of rubber can enhance this function. High-friction lagging rubber ensures that clutches engage and disengage smoothly while maintaining safety and control in operations. This capability is essential, especially in applications where precision is crucial, such as in automated systems or heavy-duty vehicles.

The customization of lagging rubber is another notable aspect. Different industries may require specific properties, such as varying thicknesses, surface textures, or resistance to particular chemicals. Manufacturers of lagging rubber can tailor products to meet these unique demands, ensuring that clients receive a solution that fits their exact operational needs. This level of customization contributes to the versatility of lagging rubber and its widespread use across different sectors.

It is also important to consider the environmental implications of lagging rubber. As industries become increasingly focused on sustainability, the choice of materials and manufacturing processes plays a significant role. Many manufacturers are now exploring eco-friendly options, such as using recycled rubber or developing biodegradable alternatives. By investing in sustainable lagging rubber solutions, industries can reduce their environmental footprint while maintaining the performance and reliability of their equipment.

In conclusion, lagging rubber is an indispensable material in various industrial settings due to its protective, durable, and customizable nature. By enhancing the performance and longevity of machinery, it helps companies save on maintenance costs and improve operational efficiency. As the industry continues to evolve, the advancement of lagging rubber technology and sustainability practices will further enhance its role in ensuring safe and reliable industrial operations. Whether in mining, manufacturing, or any other sector, the strategic use of lagging rubber will remain a key factor in optimizing performance and productivity.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025