Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

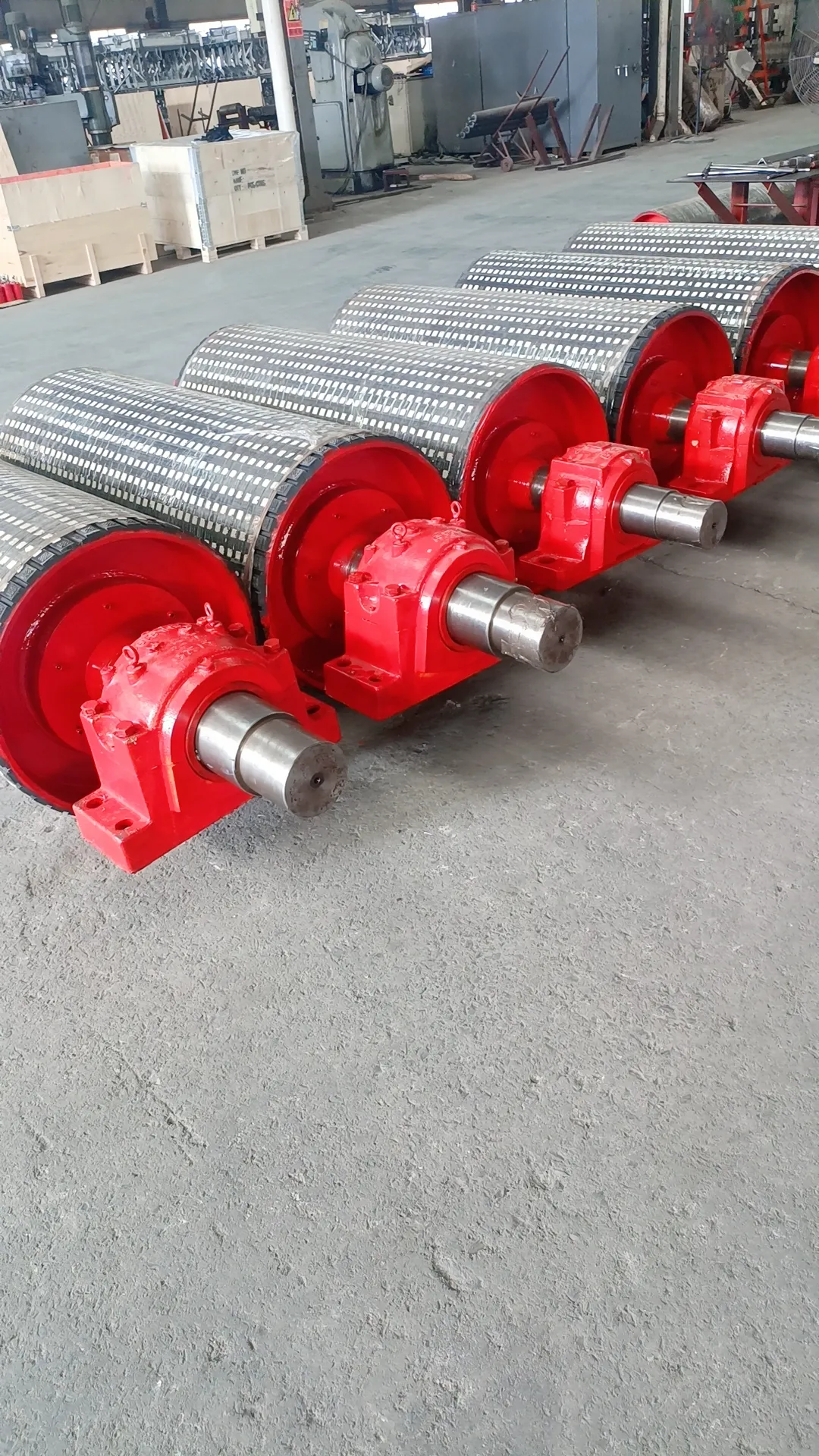

Zulu lagged head pulley

Understanding the Lagged Head Pulley in Mechanical Systems

In mechanical systems, particularly in the realms of manufacturing and material handling, the efficient transfer of power and movement is crucial for optimal performance. One component that plays a significant role in this context is the lagged head pulley. This article will explore the definition, function, and importance of the lagged head pulley, as well as its applications and maintenance considerations.

What is a Lagged Head Pulley?

A lagged head pulley is a type of pulley that features a lagging material, typically rubber, bonded to its surface. This lagging provides increased friction between the pulley and the conveyor belt that runs over it. The primary purpose of lagging is to enhance the grip of the pulley, thereby facilitating the efficient transmission of torque from the pulley to the belt. This is particularly important in situations where the belt needs to handle heavy loads or navigate steep inclines.

Function of the Lagged Head Pulley

The lagged head pulley is an integral part of conveyor systems, which are widely used in industries such as mining, agriculture, and manufacturing. When materials are transported along a conveyor belt, the lagged head pulley serves several essential functions

1. Friction Enhancement The added friction from the lagging material helps prevent slippage. In scenarios where significant torque is required to move heavy materials, the lagging ensures that the belt remains securely in contact with the pulley.

2. Wear Resistance The lagging can protect the underlying metal pulley from wear and tear caused by the constant friction and movement of the conveyor belt. By absorbing some of the impact, the lagging prolongs the life of both the pulley and the belt.

3. Noise Reduction The presence of rubber lagging can help dampen the noise produced by the operation of conveyors, contributing to a quieter work environment.

4. Improved Traction In applications where belts may experience oil, water, or other contaminants, lagging can improve traction, ensuring that the conveyor system operates smoothly and efficiently.

Applications of Lagged Head Pulleys

Lagged head pulleys can be found in a variety of industrial applications. Some common uses include

lagged head pulley

- Mining Operations In mining, heavy materials such as ores and minerals are transported, often involving steep conveyors. Lagged pulleys help manage the substantial load and gradient challenges.

- Food Processing In food industries, conveyors are used to move products through different stages of production. The rubber lagging helps in maintaining hygiene and provides adequate support for the belt.

- Material Handling in Warehouses Many warehouses rely on conveyor systems to efficiently move goods. Lagged head pulleys ensure that products are transported without delays or mishaps.

Maintenance Considerations

To ensure that lagged head pulleys perform optimally, regular maintenance is essential. Here are a few tips

1. Inspection Regularly inspect the lagging for wear, cracks, or peeling. Any signs of damage should be addressed immediately to prevent further issues.

2. Cleaning Keep the pulleys clean and free from debris that could affect the traction and performance.

3. Alignment Ensure that the pulleys are properly aligned with the conveyor system. Misalignment can lead to uneven wear and premature failure.

4. Replacement When the lagging material shows signs of deterioration, it should be replaced to maintain the efficacy of the entire system.

Conclusion

The lagged head pulley is a critical component of conveyor systems, providing the necessary friction and support to ensure efficient material handling. Understanding its role and implementing proper maintenance practices can significantly enhance the reliability and performance of mechanical systems in various industrial settings. As industries continue to evolve, the importance of such components will remain paramount to achieving higher efficiency and productivity.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025