Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Innovative Steel Drum Pulleys for Enhanced Efficiency and Durability in Material Handling Applications

The Role of Steel Drum Pulleys in Industrial Applications

In the world of industrial machinery, the efficiency and reliability of components play a crucial role in productivity. Among these components, steel drum pulleys stand out due to their durability and versatility in various applications. This article explores the significance of steel drum pulleys, their construction, benefits, and diverse applications in modern industries.

Understanding Steel Drum Pulleys

Steel drum pulleys are cylindrical devices made from high-grade steel, designed to guide and manage the movement of ropes, cables, or belts within machinery. They serve as pivotal elements in systems where heavy loads must be lifted or moved with precision. The robust steel material ensures that these pulleys can withstand substantial wear and tear, making them ideal for high-stress environments.

Construction and Design

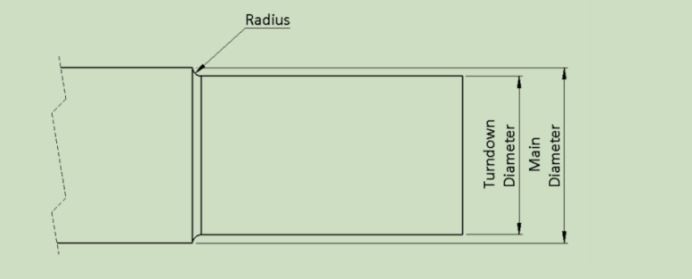

The design of steel drum pulleys is engineered to optimize performance while minimizing maintenance. They come in various sizes and designs, including heavy-duty and lightweight versions, to meet the specific demands of different applications. A typical steel drum pulley features a smooth surface to reduce friction and prolong the life of the belt or cable it interacts with. Many designs include grooves or flanges to secure the belt in place, ensuring that it operates safely and efficiently.

Benefits of Steel Drum Pulleys

1. Durability Steel is inherently strong, making it resistant to deformation and damage. This characteristic is essential in environments where pulleys endure extreme conditions, such as high temperatures, moisture, or chemical exposure.

steel drum pulley

2. Low Maintenance The robust nature of steel drum pulleys means they require minimal maintenance. Regular inspections are often sufficient to ensure optimal performance, which helps reduce downtime and maintenance costs in industrial settings.

3. Versatility Steel drum pulleys can be used in various applications across different industries, including construction, manufacturing, mining, and shipping. Their adaptability makes them a staple in many mechanical systems.

4. Safety Many steel drum pulleys are designed with safety features, such as high friction surfaces and secure fastening systems, to prevent slippage and accidents during operation.

Applications in Industry

Steel drum pulleys are employed in a multitude of industrial settings. In construction, they are commonly used in cranes and hoisting equipment to lift heavy materials to significant heights efficiently. In manufacturing, these pulleys facilitate the movement of conveyor belts that transport goods through assembly lines.

In the mining industry, steel drum pulleys are vital for transporting ores and materials from mining sites, where durability under heavy loads is imperative. Shipping and logistics hubs also utilize these pulleys to manage the movement of containers and heavy equipment, ensuring safe and timely operations.

Conclusion

Steel drum pulleys are integral to the smooth operation of various industrial applications. Their strength, low maintenance requirements, and versatility make them an essential component in environments where efficiency is paramount. As industries continue to evolve and demand greater efficiency and reliability, the role of steel drum pulleys will remain crucial in ensuring operational success. Their ability to withstand the rigors of heavy-duty environments while maintaining performance positions them as indispensable tools in the arsenal of industrial machinery. Understanding and optimizing the use of steel drum pulleys can lead to enhanced productivity and safer work environments across the board.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025