Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu industrial conveyor pulleys

The Importance of Industrial Conveyor Pulleys in Modern Manufacturing

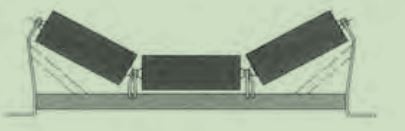

In today's fast-paced industrial world, efficiency is paramount. One of the key components that contribute to the smooth operation of manufacturing processes is the conveyor system, particularly the conveyor pulleys. These seemingly simple components play a critical role in the functionality and reliability of conveyor systems used in various industries, including manufacturing, mining, warehousing, and logistics.

Understanding Conveyor Pulleys

Conveyor pulleys are cylindrical devices that serve multiple purposes in a conveyor system. They are mainly used to support the conveyor belt, control its movement, and facilitate the transfer of materials from one place to another. The two primary types of pulleys used in conveyor systems are drive pulleys and driven pulleys. Drive pulleys are powered by a motor and are responsible for moving the belt, while driven pulleys, also known as idlers, support the belt and help maintain its tension.

Types of Conveyor Pulleys

1. Drive Pulleys These are the pulleys that are directly connected to the power source. They convert electrical energy into mechanical energy, causing the belt to move. Depending on the application, drive pulleys can be designed as lagged or bare, with lagged pulleys providing better traction and grip.

2. Tail Pulleys Located at the end of the conveyor system, tail pulleys help in returning the belt back to the drive pulley. They are crucial for maintaining belt tension and alignment.

3. Snub Pulleys These pulleys provide additional contact points with the conveyor belt, helping to increase the wrap angle around the drive pulley. This design feature enhances the grip and prevents slippage, ensuring a smooth material transfer.

4. Take-Up Pulleys These pulleys are used to adjust belt tension. They help accommodate the elongation of the belt over time, which is a natural occurrence in any moving belt system. Proper tension management is essential in preventing belt misalignment and excessive wear.

industrial conveyor pulleys

Benefits of Using Quality Conveyor Pulleys

1. Increased Efficiency High-quality conveyor pulleys enhance the overall efficiency of the conveyor system. They reduce friction, allowing for smoother belt movement and, consequently, quicker material transport. This efficiency translates into increased productivity in manufacturing and logistics operations.

2. Reduced Maintenance Costs Investing in durable pulley systems minimizes wear and tear on the conveyor belt and other components. Quality pulleys require less frequent replacements and repairs, lowering maintenance costs over time.

3. Improved Safety Conveyor systems can pose safety hazards if not properly maintained. Quality pulleys contribute to the stability of the conveyor belt, reducing the likelihood of accidents caused by belt slippage or misalignment.

4. Versatility Conveyor pulleys are versatile and can be engineered to suit a wide array of applications. Whether dealing with heavy materials in mining or light products in retail, there are pulleys designed to meet specific operational needs.

5. Enhanced Material Handling Different industries handle various types of materials, from raw goods to manufactured products. Conveyor pulleys designed with specific material handling capabilities can optimize the transport process, ensuring that goods are moved efficiently and effectively.

Conclusion

As industries continue to evolve and expand, the importance of reliable and efficient conveyor systems cannot be overstated. Conveyor pulleys play a pivotal role in this landscape, serving as the backbone of material handling systems. Industry professionals must invest in high-quality conveyor pulleys to maximize efficiency, ensure safety, and reduce operational costs. With advancements in technology and materials, the future of conveyor pulleys looks bright, promising even greater performance and reliability.

In essence, understanding the role and importance of industrial conveyor pulleys is critical for businesses aiming to improve their manufacturing and logistics processes. As the demand for efficient and automated systems rises, conveyor pulleys will remain a crucial element in shaping the future of industrial operations, driving productivity and innovation forward.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025