Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu impact idlers are used in a belt conveyor at mcq

Understanding Impact Idlers in Belt Conveyors An Overview

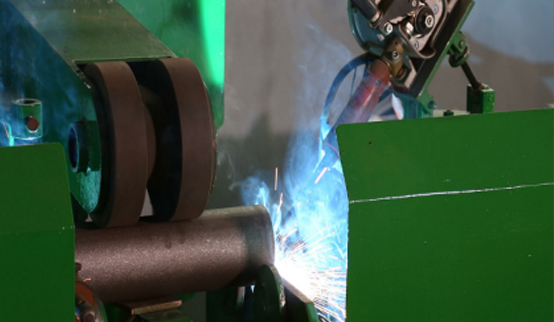

Belt conveyors are essential components in many industrial operations, facilitating the efficient movement of materials across various distances. Among the many components that ensure the smooth operation of these conveyors is the impact idler. Understanding the role and importance of impact idlers can enhance the efficiency and longevity of belt conveyor systems.

What are Impact Idlers?

Impact idlers are specialized rollers designed to absorb the energy generated by falling materials onto the conveyor belt. Typically located at transfer points or loading zones, impact idlers are crucial for protecting the belt from potential damage. They are constructed from robust materials that can withstand high impacts, making them ideal for handling heavy or bulk materials.

Functionality and Benefits

The primary function of impact idlers is to minimize the shock and stress exerted on the conveyor belt

. When materials are loaded onto the belt, they often fall from a height, which can create a significant impact. If unprotected, this can lead to premature wear and tear of the belt, resulting in costly repairs and downtime.impact idlers are used in a belt conveyor at mcq

1. Shock Absorption Impact idlers effectively absorb and distribute the energy of the falling materials, thus reducing the immediate impact on the belt. This capability prolongs the lifespan of the belt and minimizes the need for frequent replacements.

2. Material Flow Optimization By cushioning the impact, impact idlers contribute to a smoother material flow. This is particularly important in maintaining the speed and efficiency of the conveyor system, ensuring uninterrupted operations.

3. Reduced Maintenance Costs Investing in high-quality impact idlers can lead to significant cost savings in the long run. By preventing damage to the belt and other components, companies can reduce maintenance efforts and associated expenses.

4. Improved Safety Crushers and other heavy machinery often present safety risks in an industrial setting. By reducing the likelihood of material spillage and minimizing equipment wear, impact idlers contribute to a safer working environment.

Conclusion

Incorporating impact idlers into belt conveyor systems is a prudent decision for organizations looking to enhance operational efficiency and reduce maintenance costs. Their ability to mitigate the effects of heavy loads not only protects the conveyor belt but also promotes a safer and more productive workplace. By understanding the crucial role of impact idlers, industries can better maintain their conveyor systems and optimize their material handling processes. Investing in such components is not just a matter of cost but one of ensuring sustained operational excellence.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025