Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu impact idlers are used in a belt conveyor at

The Role of Impact Idlers in Belt Conveyors

Belt conveyors are one of the most widely used methods for transporting bulk materials in various industries, including mining, agriculture, and manufacturing. Their efficiency relies heavily on the design and components used in their construction. One critical component that plays a pivotal role in the performance and longevity of belt conveyors is the impact idler. Understanding the function and importance of impact idlers in belt conveyors can provide valuable insights into optimizing material handling systems.

What are Impact Idlers?

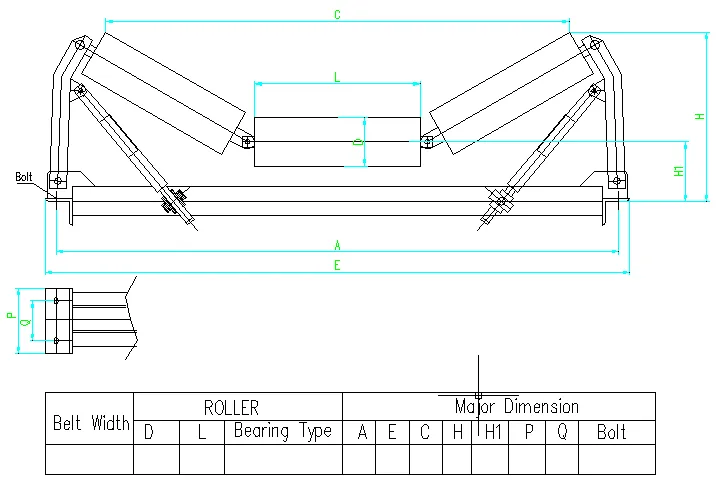

Impact idlers, also known as impact rollers, are specialized rollers designed to support the belt in areas where material is loaded onto it. Their primary function is to absorb the shock and impact caused by heavy materials falling onto the conveyor belt. This absorption mitigates the stress on the belt, preventing damage and prolonging its lifespan.

Impact idlers are typically constructed with robust materials, often featuring heavier-duty designs than standard idlers. This strength is necessary to withstand the pressures exerted by materials during loading operations. The design may include a series of spaced rollers to distribute the load more evenly and minimize wear on the belt.

Importance of Impact Idlers

1. Protection against Damage One of the foremost benefits of using impact idlers is their ability to protect the conveyor belt from damage. Without adequate support and shock absorption, the belt could suffer rips and tears, leading to costly downtime and repairs. By using impact idlers at loading zones, operators can significantly reduce the risk of such wear and tear.

impact idlers are used in a belt conveyor at

2. Improved Material Flow The presence of impact idlers can enhance the flow of materials onto the conveyor belt. Their design allows for a smoother transition of bulk materials, reducing the likelihood of spillage. This improvement in flow directly contributes to the overall efficiency of the loading process and minimizes material loss.

3. Extended Operational Life The wear and tear on conveyor systems can be intense, particularly in high-stress environments like mines or heavy manufacturing facilities. Impact idlers help to extend the operational life of the conveyor system by reducing the aggressive impacts that can lead to structural failure of the belt or other components. This durability ultimately translates to lower maintenance costs and enhanced productivity.

4. Noise Reduction The shock absorption characteristics of impact idlers also play a role in noise reduction. As heavy materials impact the belt, noise levels can rise significantly. Impact idlers help dampen these sounds, creating a more pleasant work environment for operators and reducing noise pollution in nearby areas.

5. Versatility Across Industries Impact idlers are versatile and can be utilized in a variety of industries. From the heavy loads of mining to the lighter conveying of agricultural products, impact idlers can be adapted to meet the specific requirements of different applications. This adaptability makes them a vital component in many conveyor systems.

Conclusion

In conclusion, impact idlers are essential for the proper functioning and longevity of belt conveyors. Their ability to absorb shocks, protect the belt, improve material flow, and reduce noise makes them a critical component in the material handling process. By investing in quality impact idlers, businesses can enhance the efficiency of their operations, reduce maintenance costs, and prolong the life of their conveyor systems. As industries continue to evolve and demand more from their material handling solutions, the significance of impact idlers will only grow, underscoring their vital role in modern conveyor technology.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025