Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

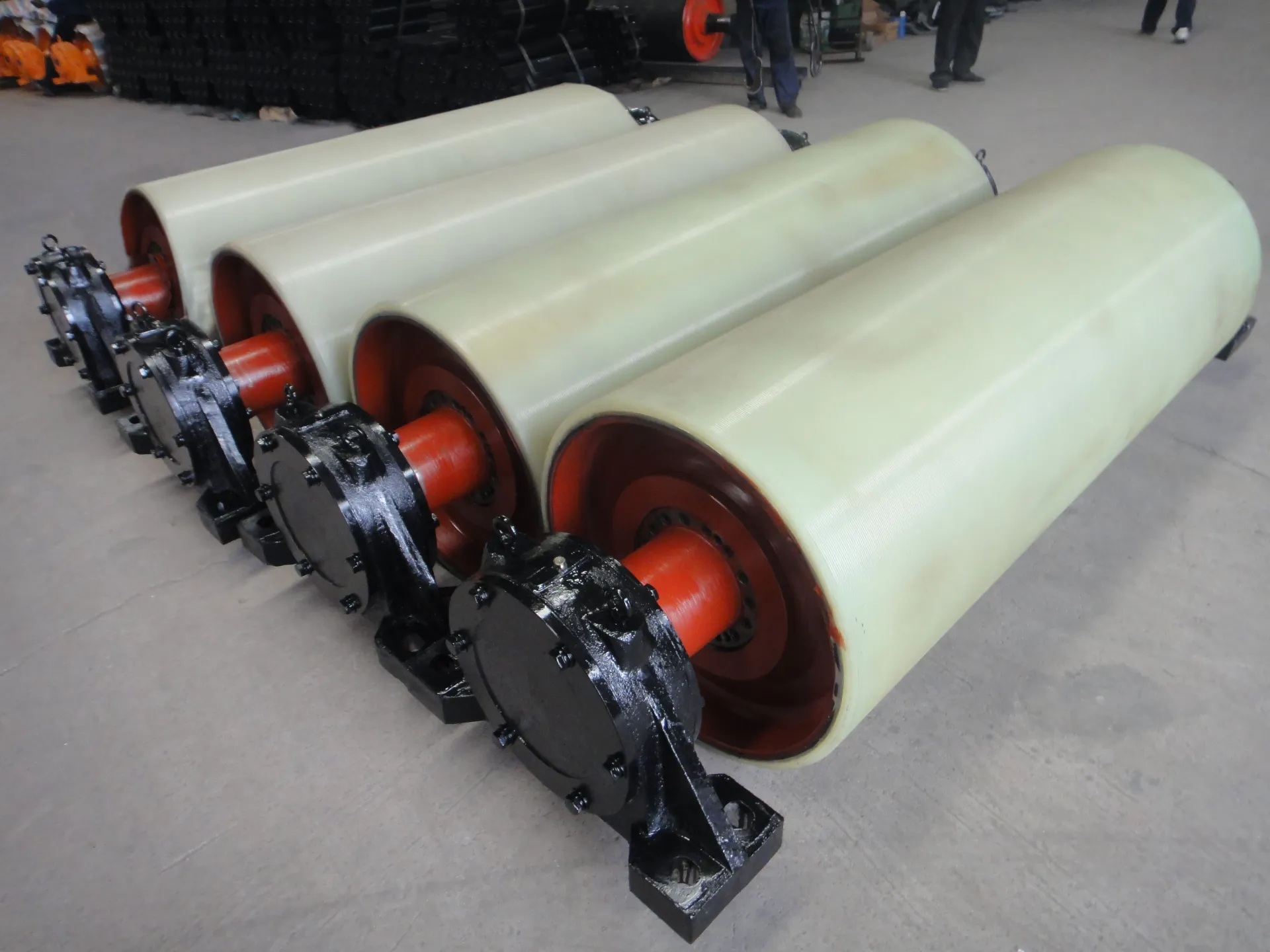

Zulu impact idlers are used in a belt conveyor

The Role of Impact Idlers in Belt Conveyors

Belt conveyors are essential components in various industries, facilitating the efficient movement of goods and materials across different locations. Among the various elements that contribute to the effective operation of a belt conveyor, impact idlers play a pivotal role. These idlers are specially designed to support the belt in high-impact sections of the conveyor, ensuring longevity, stability, and optimal performance.

Understanding Impact Idlers

Impact idlers are a type of roller used in the design of belt conveyors, strategically placed in areas where material falls onto the belt, such as at loading points. Their primary function is to absorb the shock from heavy loads and prevent damage to the conveyor system. Unlike standard idlers, impact idlers are built with a robust structure and often feature extra cushioning or shock-absorbent materials to reduce the impact forces that act on the belt and other supporting components.

Importance of Impact Idlers

1. Protection of the Conveyor System The conveyor belt and its structure are susceptible to wear and tear, especially when heavy materials are dropped onto them. Impact idlers mitigate this damage by absorbing the energy from the falling materials, thus prolonging the life of the belt and minimizing maintenance costs.

2. Enhanced Performance By reducing the impact loads, idlers help maintain the alignment and stability of the conveyor system. This ensures smoother operation, decreased likelihood of belt misalignment, and better overall material handling performance. This is crucial for industries where efficiency and reliability are paramount.

3. Adaptation to Different Materials Different materials have varying weights and drop heights. Impact idlers can be designed to handle specific material types and their associated impacts, making them highly versatile. Industries ranging from mining to manufacturing can benefit from tailored solutions that cater to their unique challenges.

impact idlers are used in a belt conveyor

4. Energy Efficiency By minimizing the energy dissipated during impacts, impact idlers contribute to the energy efficiency of the entire conveyor system. This not only reduces operating costs but also contributes to a more sustainable industrial process as it lowers energy consumption and carbon footprint.

5. Safety Considerations Safety is a major concern in any operational environment. Impact idlers help maintain the integrity of the conveyor system, which reduces the likelihood of accidents caused by equipment failure. A well-maintained conveyor translates into a safer workplace, ultimately benefiting the workforce.

Installation and Maintenance

Installing impact idlers involves careful consideration of the specific requirements of the conveyor system. Factors such as load weight, material type, and drop height must be assessed to ensure the appropriate idlers are chosen. Proper alignment and spacing are also critical to maximizing their effectiveness.

Routine maintenance checks of impact idlers should be part of a broader conveyor maintenance program. Inspecting for wear and ensuring that the cushioning materials are in good condition will help maintain peak performance and further extend the lifespan of the conveyor system.

Conclusion

In summary, impact idlers are indispensable components of belt conveyors that significantly enhance their operational efficiency and longevity. By absorbing shocks, protecting the system, and ensuring safety, they play a vital role in various industrial applications. As industries continue to evolve and demand more from their conveyor systems, the importance of implementing specialized solutions like impact idlers becomes even more pronounced. Investing in quality impact idlers is, therefore, not just an operational necessity but a strategic move towards sustainable and efficient material handling.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025