Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Impact Bed Conveyor - Reliable Conveyor Solutions for Efficient Material Handling

Impact Bed Conveyors Revolutionizing Material Handling

In the rapidly evolving world of industrial automation and material handling, impact bed conveyors are gaining prominence for their efficiency and effectiveness. These conveyors are designed to minimize material impact during transfers, thereby reducing wear and tear on both the material and the equipment itself. This article explores the key features, benefits, and applications of impact bed conveyors.

What are Impact Bed Conveyors?

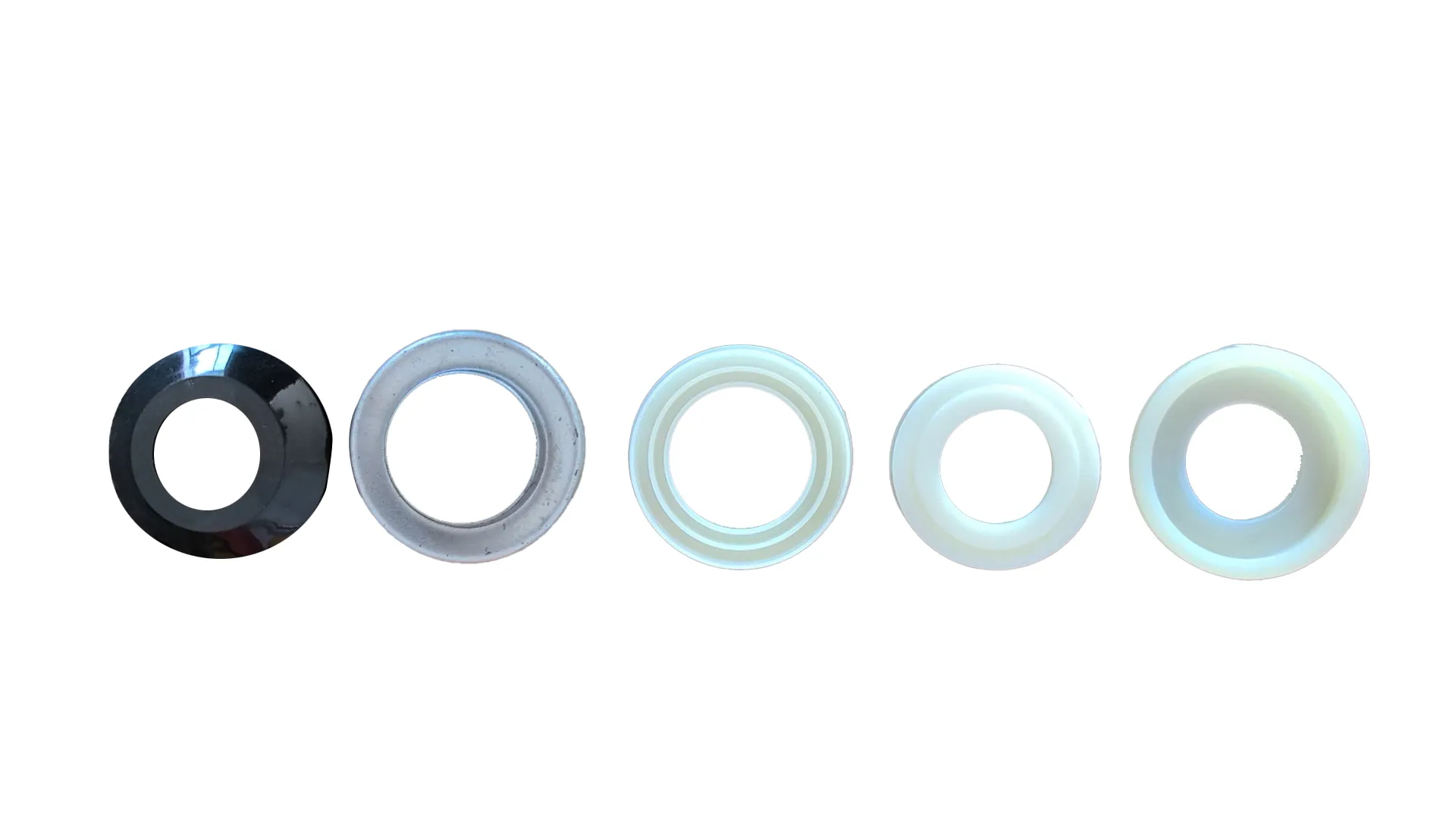

Impact bed conveyors are specialized conveyor systems equipped with a bed that absorbs the energy of materials as they are transferred. The bed, typically made from a combination of rubber and metal, provides a cushioning effect that protects the conveyor and the material being transported. This design is particularly beneficial for handling heavy or abrasive materials, as the impact bed can significantly reduce the damage caused by falling objects.

Key Features and Benefits

One of the primary advantages of impact bed conveyors is their ability to extend the lifespan of the conveyor system. Traditional conveyors can suffer from excessive wear, especially at points where materials drop or shift. This not only increases maintenance costs but also leads to unscheduled downtime. Impact beds help mitigate these issues by evenly distributing the impact energy across a larger surface area, thereby reducing localized wear.

Another noteworthy feature of impact bed conveyors is their versatility. They can be customized to accommodate a wide range of materials, including bulk materials like aggregates, grains, and chemicals. This makes them an ideal choice for industries such as mining, construction, and agriculture, where the type of material handled can vary significantly.

impact bed conveyor

Furthermore, impact bed conveyors facilitate better operational safety. By providing a stable surface for material transfer, they minimize the risk of spillage, which can lead to hazardous working conditions. Additionally, with less wear and damage, the chances of conveyor failure reduce, creating a safer work environment for employees.

Applications

Impact bed conveyors are used in various applications across multiple industries. In mining operations, for instance, they are employed to transport coal, minerals, and other bulk materials. The cushioning effect of the impact bed reduces the potential for breakage, allowing for the efficient transportation of these materials without significant loss.

In food processing, impact bed conveyors are utilized to handle fragile products such as fruits and vegetables. The gentle transfer provided by the impact bed ensures that these products arrive at their destination without bruising or damage. Similarly, in the recycling industry, impact bed conveyors assist in the efficient handling of recyclable materials, protecting the integrity of the items being processed.

Conclusion

In conclusion, impact bed conveyors represent a significant advancement in material handling technology. Their ability to reduce wear and tear on equipment, enhance operational safety, and accommodate a variety of materials makes them an invaluable asset in numerous industries. As businesses continue to seek more efficient and sustainable solutions for material handling, the popularity of impact bed conveyors is likely to rise, cementing their place as a cornerstone of modern industrial operations. By investing in such technology, companies can not only improve their operational efficiency but also contribute to a safer work environment.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025