Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 11, 2025 09:25

Back to list

idler roller types

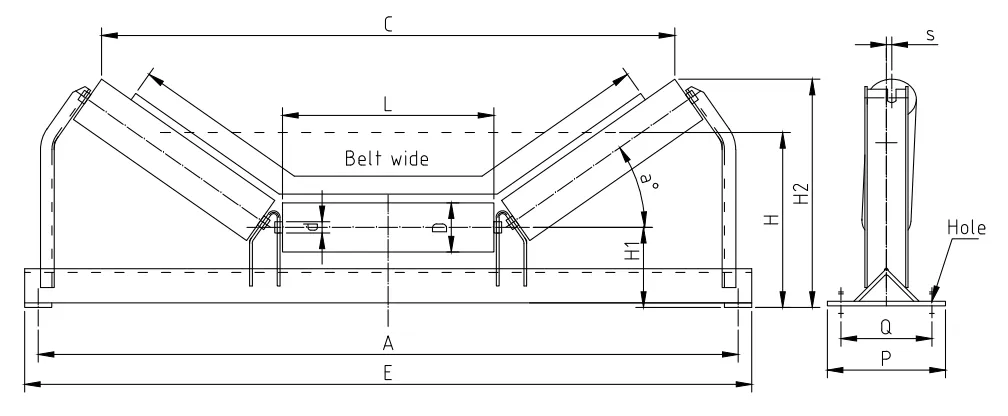

In the world of conveyor systems, idler rollers play a pivotal role in maintaining system efficiency and prolonging the life of the conveyor belt. Different applications and environments demand distinct types of idler rollers, each designed to meet specific operational challenges. Understanding these types helps in selecting the right product, ensuring optimal performance and longevity.

Another important type is the impact idler roller, designed specifically to absorb the impact at loading points where material is dumped onto the conveyor belt. These idlers have a robust construction, often with rubber rings or pads, which absorb shock and protect the belt and structure from damage. For industries handling heavy and abrasive materials, impact idlers help reduce belt wear and prevent damage to conveyor components, crucial for maintaining uptime and reducing costly repairs. For environments with specific needs, such as chemical resistance or operability at elevated temperatures, specialized idler rollers like stainless steel or ceramic-coated rollers are available. These variants are tailored to offer superior performance under challenging conditions, ensuring safety and compliance with industry standards. Selecting the right material is critical in such cases to avoid contamination, corrosion, or premature failure. In conclusion, the type of idler rollers you choose directly influences the effectiveness and durability of your conveyor systems. Leveraging expert insights in selecting the right idler roller type tailored to your specific application can significantly enhance operational efficiency and reliability. It is crucial to consult with specialists and consider all operational parameters and environmental factors when making your selection to ensure that you build a resilient and efficient conveyor system. This strategic approach will not only improve performance but also build trust with stakeholders, reinforcing your authority and expertise within your industry.

Another important type is the impact idler roller, designed specifically to absorb the impact at loading points where material is dumped onto the conveyor belt. These idlers have a robust construction, often with rubber rings or pads, which absorb shock and protect the belt and structure from damage. For industries handling heavy and abrasive materials, impact idlers help reduce belt wear and prevent damage to conveyor components, crucial for maintaining uptime and reducing costly repairs. For environments with specific needs, such as chemical resistance or operability at elevated temperatures, specialized idler rollers like stainless steel or ceramic-coated rollers are available. These variants are tailored to offer superior performance under challenging conditions, ensuring safety and compliance with industry standards. Selecting the right material is critical in such cases to avoid contamination, corrosion, or premature failure. In conclusion, the type of idler rollers you choose directly influences the effectiveness and durability of your conveyor systems. Leveraging expert insights in selecting the right idler roller type tailored to your specific application can significantly enhance operational efficiency and reliability. It is crucial to consult with specialists and consider all operational parameters and environmental factors when making your selection to ensure that you build a resilient and efficient conveyor system. This strategic approach will not only improve performance but also build trust with stakeholders, reinforcing your authority and expertise within your industry.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS