Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 09, 2025 10:58

Back to list

Premium Idler Roller Manufacturer Quality & Trust

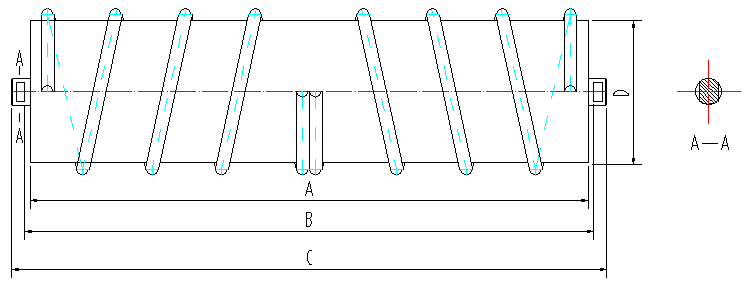

In the world of industrial machinery, idler rollers play a crucial role in ensuring the smooth operation of conveyor systems. As components that support and guide the belt, their performance is integral to the efficiency and longevity of the entire system. This article delves into the essential factors that define a reputable idler roller manufacturer and explores how their expertise transforms industrial operations.

Trustworthiness is bolstered by adherence to international standards and certifications. Leading manufacturers commit to rigorous testing procedures and quality assurance protocols. By complying with global standards such as ISO 9001, they not only guarantee product excellence but also instill confidence in their clients. This transparency and accountability establish the manufacturer as a reliable partner in industrial operations. Real-world experience further substantiates a manufacturer’s credibility. Long-standing partnerships with major corporations and documented case studies demonstrate their capability to deliver results. Client testimonials offer authentic insights into how these manufacturers have enhanced operational efficiencies, highlighting their role as trustworthy advisors in optimizing conveyance systems. It is crucial for businesses searching for an idler roller manufacturer to evaluate these aspects meticulously. A thorough examination of the manufacturer's expertise, authority, and trustworthiness can lead to significant improvements in system performance. Collaborating with a seasoned manufacturer aligns technological advancements with business goals, positioning companies to excel in competitive landscapes. In conclusion, an exceptional idler roller manufacturer is defined by their commitment to precision, customization, innovation, and adherence to stringent quality standards. Their expertise and authority are reflected in their cutting-edge solutions, designed to tackle the complex challenges of today’s industrial environments. As trusted partners, they empower businesses to enhance efficiency, ensuring their conveyor systems operate seamlessly and sustainably.

Trustworthiness is bolstered by adherence to international standards and certifications. Leading manufacturers commit to rigorous testing procedures and quality assurance protocols. By complying with global standards such as ISO 9001, they not only guarantee product excellence but also instill confidence in their clients. This transparency and accountability establish the manufacturer as a reliable partner in industrial operations. Real-world experience further substantiates a manufacturer’s credibility. Long-standing partnerships with major corporations and documented case studies demonstrate their capability to deliver results. Client testimonials offer authentic insights into how these manufacturers have enhanced operational efficiencies, highlighting their role as trustworthy advisors in optimizing conveyance systems. It is crucial for businesses searching for an idler roller manufacturer to evaluate these aspects meticulously. A thorough examination of the manufacturer's expertise, authority, and trustworthiness can lead to significant improvements in system performance. Collaborating with a seasoned manufacturer aligns technological advancements with business goals, positioning companies to excel in competitive landscapes. In conclusion, an exceptional idler roller manufacturer is defined by their commitment to precision, customization, innovation, and adherence to stringent quality standards. Their expertise and authority are reflected in their cutting-edge solutions, designed to tackle the complex challenges of today’s industrial environments. As trusted partners, they empower businesses to enhance efficiency, ensuring their conveyor systems operate seamlessly and sustainably.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS