Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu idler roller manufacturer

Understanding the Role of Idler Roller Manufacturers in Modern Industries

Idler rollers play a crucial role in various industries, particularly in material handling and conveyor systems. These components are essential for ensuring smooth and efficient operations, enhancing the lifespan of machinery, and minimizing maintenance costs. As demand for efficient material handling solutions rises, idler roller manufacturers are becoming increasingly integral to various sectors.

What is an Idler Roller?

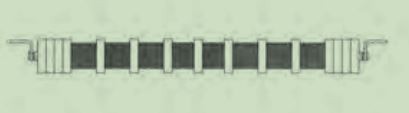

Idler rollers are specialized cylindrical components that facilitate the transport of materials within conveyor systems. They are primarily used to support and guide the conveyor belt, ensuring that it operates smoothly. Unlike drive rollers, which are powered and contribute to the motion of the belt, idler rollers remain passive, allowing the belt to slide over them. Their primary purpose is to reduce friction, provide stability, and help in the alignment of the conveyor system.

The Importance of Idler Roller Manufacturers

Idler roller manufacturers are responsible for designing and producing these essential components. The quality and specifications of idler rollers can significantly impact the efficiency and durability of conveyor systems. Here are several key reasons why these manufacturers are pivotal to industrial operations

1. Customization and Innovation Different industries may require specific types of idler rollers tailored to their unique needs. For instance, roller size, material, and design can vary greatly between heavy-duty mining applications and lightweight packaging environments. Manufacturers strive to innovate and offer customized solutions that enhance operational efficiency.

2. Quality Assurance High-quality idler rollers minimize wear and tear on other conveyor components, extending the overall lifespan of the system. Reputable manufacturers adhere to strict quality control processes, utilizing advanced materials such as stainless steel, plastic, or rubber, which can withstand diverse environmental conditions, ensuring durability and reliability.

idler roller manufacturer

3. Cost Efficiency By investing in high-quality idler rollers, businesses can significantly reduce their maintenance costs. Durable products lead to lesser breakdowns and replacements, providing a better return on investment over time. Manufacturer innovations, such as improved roller bearings and seals, further contribute to cost efficiencies by reducing energy consumption and downtime.

4. Sustainability Practices As industries increasingly focus on sustainability, many idler roller manufacturers are adopting eco-friendly practices. This can include using recyclable materials in their products, waste reduction techniques in manufacturing, and developing more energy-efficient designs. These practices not only meet regulatory standards but also appeal to environmentally conscious customers.

5. Technical Support and Consultation A key value-add from idler roller manufacturers is their technical expertise. Many manufacturers offer design consultation, helping clients select the right products for their specific applications. They provide support in both product selection and installation, ensuring that businesses can optimize their conveyor systems for peak performance.

Choosing the Right Idler Roller Manufacturer

When selecting an idler roller manufacturer, businesses should consider factors such as industry experience, production capabilities, quality certifications, and customer testimonials. It is vital to partner with a manufacturer who has a proven track record of delivering high-quality products and reliable service.

Investing time in research can yield benefits such as better product performance, enhanced operational efficiency, and ultimately, greater profitability. Close collaboration with a manufacturer who understands industry-specific challenges allows businesses to develop tailored solutions that meet their unique needs.

Conclusion

In conclusion, idler roller manufacturers are essential players in the landscape of modern industrial operations. By providing high-quality, customized solutions, these manufacturers help enhance the efficiency, reliability, and sustainability of conveyor systems across various sectors. As industries continue to evolve, the role of idler roller manufacturers will remain significant, ensuring that operations not only meet current demands but are well-prepared for future challenges.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025