Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Top Idler Roller Suppliers for Efficient Material Handling Solutions

The Importance of Idler Roller Manufacturers in Modern Industry

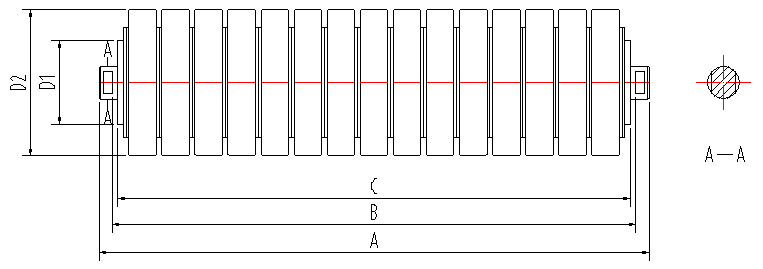

Idler rollers are crucial components in various industrial applications, particularly in the fields of material handling and transportation. These rollers serve a simple yet vital purpose they support and guide belts in conveyor systems, thereby ensuring smooth and efficient operation. As industries continue to grow and evolve, the role of idler roller manufacturers becomes more significant.

The Role of Idler Rollers

Idler rollers are typically used in conveyor systems to provide a supporting structure that maintains the tension and alignment of the conveyor belt. This not only helps to reduce wear and tear on the belt but also minimizes energy consumption and increases the efficiency of the entire system. By ensuring that the conveyor belt runs smoothly over a series of idler rollers, materials can be transported safely, reducing the risk of spills or accidents.

Diverse Applications

Idler rollers are utilized across a wide array of industries, including mining, agriculture, manufacturing, and logistics. In mining operations, for instance, idler rollers are essential for transporting heavy materials over long distances. In manufacturing, they facilitate the movement of products along assembly lines, while in agriculture, they may be used in systems that transport grains or other bulk commodities. The versatility of idler rollers makes them an indispensable component in modern manufacturing and logistical operations.

Quality and Innovation in Manufacturing

idler roller manufacturer

The manufacture of idler rollers is not a simple task; it requires precision engineering and a deep understanding of material properties. Manufacturers must consider various factors, such as load capacity, friction, and durability, to create products that can withstand the rigors of industrial use. High-quality idler rollers are made from robust materials such as steel and composite materials, which can endure harsh environmental conditions.

Moreover, innovation in design and materials is constantly evolving. Manufacturers are now exploring advanced materials and different roller configurations to enhance performance further. For example, incorporating features like self-aligning designs or using materials that reduce friction can significantly improve the efficiency and lifespan of conveyor systems.

Choosing the Right Manufacturer

When sourcing idler rollers, it is crucial for businesses to select a reliable manufacturer. Factors to consider include the manufacturer's experience, product quality, after-sales support, and the ability to customize products to meet specific needs. A reputable idler roller manufacturer will not only provide high-quality products but also offer design and engineering support to ensure the right fit for unique applications.

Additionally, companies should pay attention to certifications and industry standards. A manufacturer that adheres to international safety and quality standards can provide peace of mind, ensuring that the rollers are safe and efficient for use in critical applications.

Conclusion

Idler roller manufacturers play a pivotal role in supporting the infrastructure of various industries. With the ever-increasing demand for efficiency and innovation, these manufacturers must continue to adapt and improve their products. The collaboration between businesses and idler roller manufacturers is essential for achieving operational excellence and ensuring that conveyor systems function optimally. As technology advances, the future of idler rollers promises even greater efficiency, sustainability, and performance, benefiting industries worldwide.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025