Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Design and Functionality of Idler Bearing Housings in Machinery Applications

Understanding Idler Bearing Housing A Comprehensive Overview

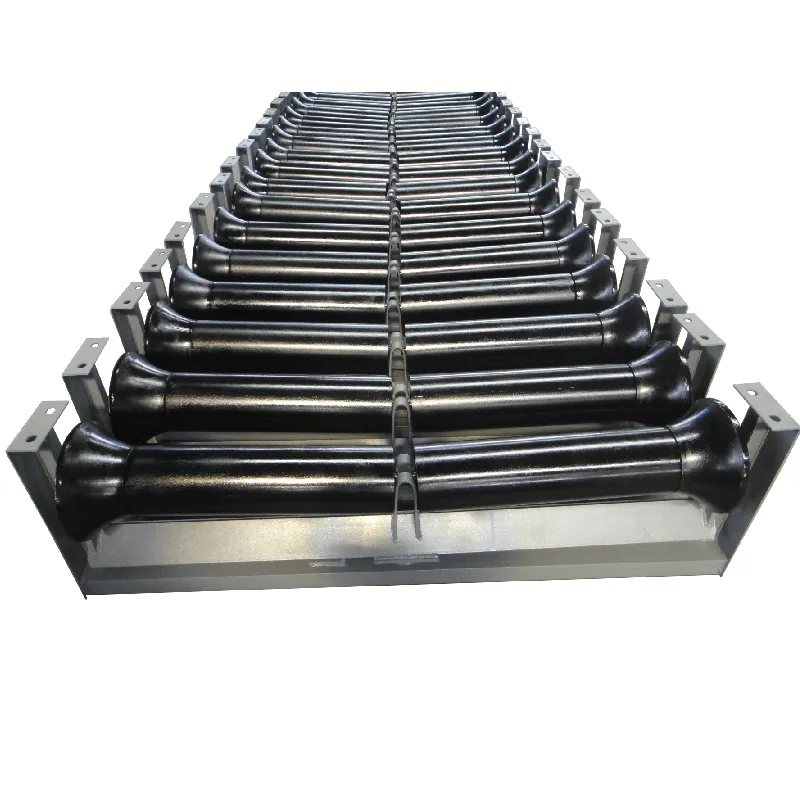

Idler bearing housing is a crucial component in various machinery and mechanical systems. It serves as a support structure for the idler bearings which, in turn, facilitate the smooth motion of rotating elements. The idler bearing itself does not drive any load but is essential for maintaining the alignment and operation of components like belts or chains in transmission systems. This article delves into the significance, design, and applications of idler bearing housing.

What is Idler Bearing Housing?

Idler bearing housing is designed to encase and support idler bearings. Typically made from materials like cast iron, steel, or high-strength polymers, these housings are engineered to withstand significant mechanical stress and environmental conditions. The main function of the housing is to provide stability and protection to the bearings, ensuring they operate efficiently and have a long service life.

Importance in Machinery

Idler bearing housings play a vital role in various industrial and commercial applications. In conveyor systems, for instance, they help maintain proper tension on belts, preventing slippage and ensuring a consistent flow of materials. In automotive applications, idler bearings support the timing belts and chains, which are crucial for synchronizing the engine's moving parts. By ensuring smooth rotation and alignment, idler bearing housing contributes significantly to the overall efficiency and reliability of mechanical systems.

Design Considerations

When designing idler bearing housing, several factors must be considered

idler bearing housing

1. Load Capacity The housing must be designed to handle the specific loads it will encounter in its application, ensuring durability and performance. 2. Material Selection The choice of material can significantly impact the housing's strength, weight, and resistance to environmental factors like corrosion or heat.

3. Dimensions The dimensions must accommodate the size of the idler bearings and any other components they interact with, ensuring a proper fit and alignment.

4. Lubrication Requirements Adequate provisions for lubrication must be included to ensure the bearings operate smoothly and reduce wear.

5. Ease of Maintenance Designing the housing with maintenance in mind can facilitate easy access for inspections and replacements, minimizing downtime.

Applications

Idler bearing housings are utilized across various industries. In the mining sector, they are integral to conveyor systems that transport materials. They are also common in manufacturing plants, where they help automate processes involving belt-driven equipment. Furthermore, in the automotive field, idler bearing housings are found in engine designs, ensuring the proper functioning of timing mechanisms.

Conclusion

In summary, idler bearing housing is an essential component that supports and protects idler bearings, which are vital for the operation of many mechanical systems. Understanding its design, functionality, and applications helps engineers and technicians ensure that machinery operates efficiently and reliably. As industries continue to evolve, the role of idler bearing housing will remain significant in enhancing performance and durability in various applications. With ongoing advancements in materials and design techniques, the future of idler bearing housings looks promising, driving innovation across multiple sectors.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025