Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Hot Vulcanized Pulley Lagging for Enhanced Durability and Performance in Industrial Applications

Hot Vulcanized Pulley Lagging Enhancing Conveyor Performance

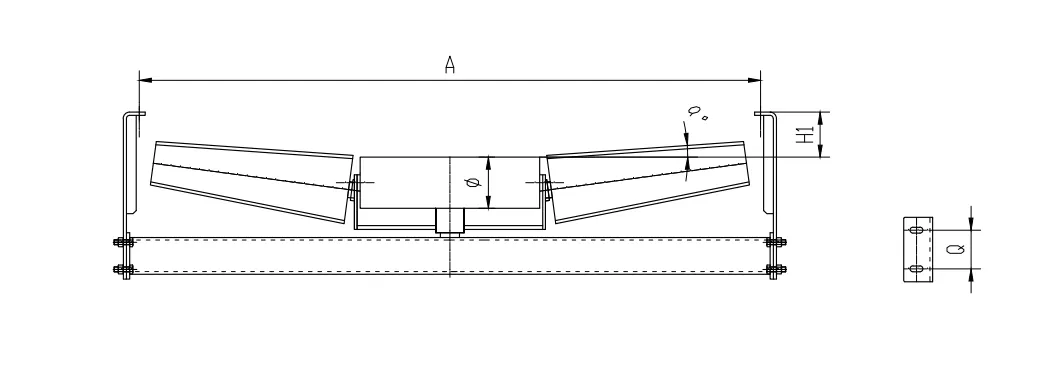

In various industrial applications, conveyor systems play a crucial role in material handling. One of the key components that ensure the efficiency and longevity of these systems is the lagging on pulleys. Among several lagging methods, hot vulcanized pulley lagging stands out for its durability and performance advantages.

Hot vulcanized pulley lagging involves the application of a rubber layer directly onto the surface of the pulley. This process utilizes heat and pressure to bond the rubber to the pulley, creating a strong, lasting connection. The result is a lagging that can withstand extreme conditions and extensive use, minimizing wear and tear on both the pulley and the conveyor belt.

One of the primary benefits of hot vulcanized lagging is its enhanced frictional grip. This increased friction reduces slippage between the pulley and the conveyor belt, leading to improved efficiency and productivity. In logistical environments where heavy loads are transported, maintaining optimal traction is essential. Hot vulcanized lagging ensures that power transfer from the pulley to the belt remains consistent, preventing costly downtimes and operational disruptions.

hot vulcanized pulley lagging

Another significant advantage of this method is its resistance to moisture and various chemicals. Industrial environments often expose machinery to harsh substances, which can degrade standard lagging materials. The robust nature of hot vulcanized rubber makes it resistant to water, oils, and other corrosive elements, allowing for a longer lifespan and reduced maintenance costs.

Moreover, hot vulcanized lagging can be tailored to meet specific operational requirements. Various rubber compounds can be used, depending on factors such as temperature, load capacity, and environmental conditions. This customization enables industries to select the most appropriate lagging for their unique challenges, whether it involves heavy-duty applications or those requiring special resistance properties.

In summary, hot vulcanized pulley lagging is an essential component in optimizing conveyor system performance. With its superior grip, durability, and tailored options, it meets the demands of modern industrial applications. By investing in high-quality lagging solutions, companies can enhance their operational efficiency, reduce maintenance requirements, and ultimately achieve greater productivity in their material handling processes. For industries looking to maximize performance and minimize risks, hot vulcanized pulley lagging represents a reliable and effective choice.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025