Jul . 01, 2024 01:10

Back to list

High-strength Conveyor Belt Roller Systems for Heavy Duty Applications

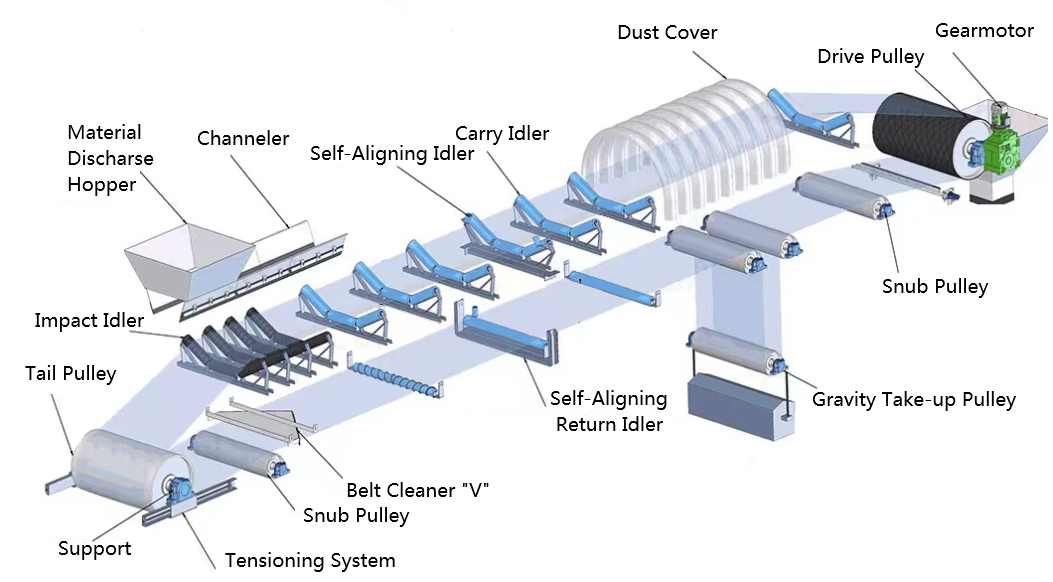

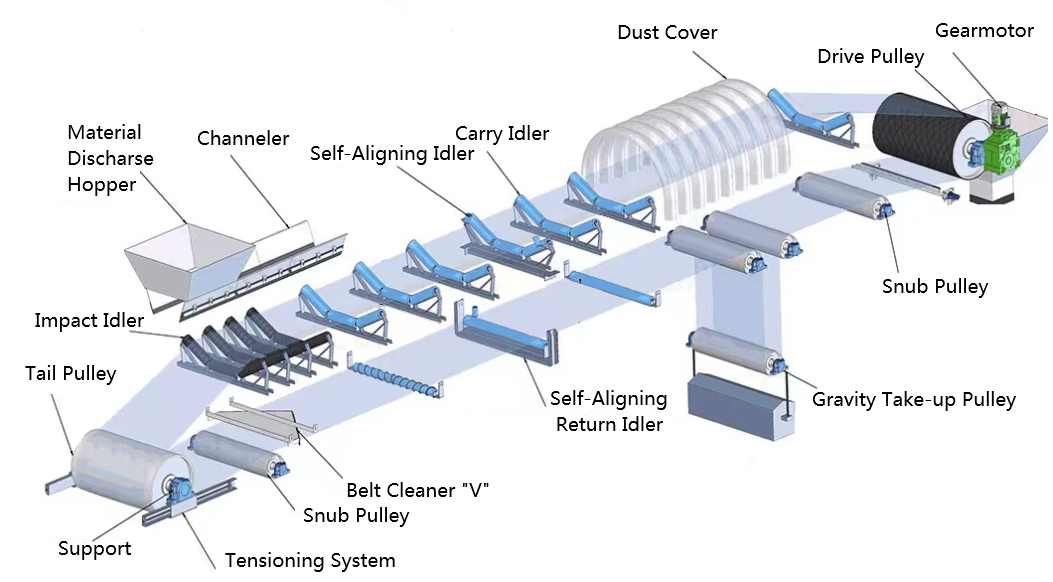

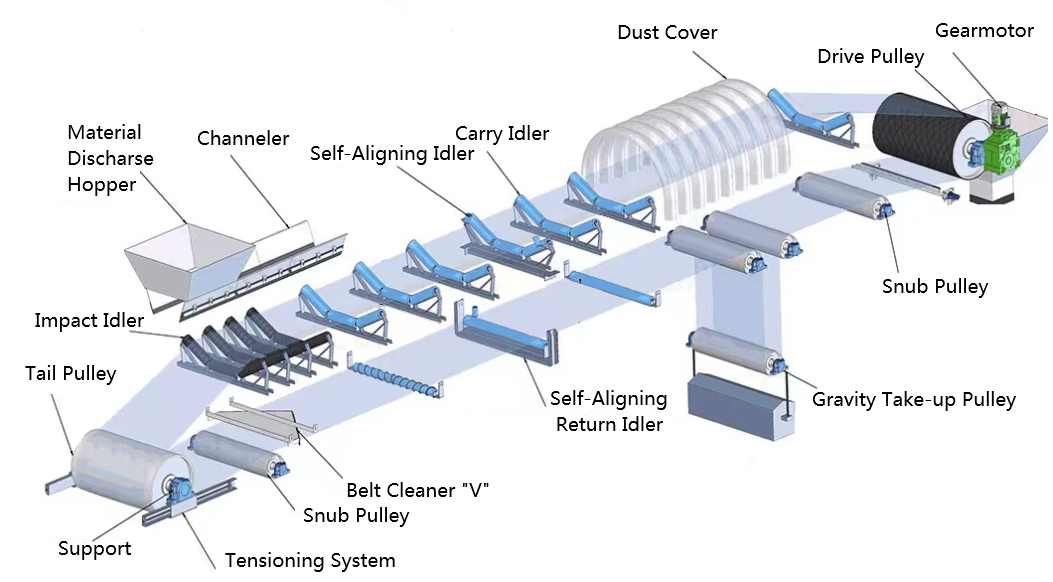

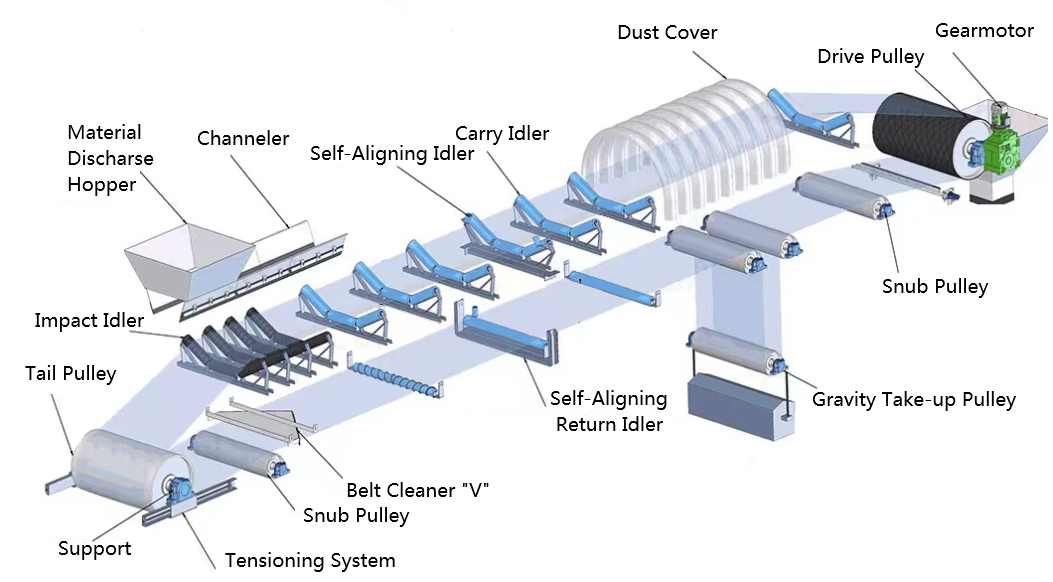

Heavy-duty conveyor belt rollers are an essential component in the industrial sector, particularly in manufacturing and logistics. These robust devices are designed to withstand high loads and operate continuously without frequent maintenance.

The construction of heavy-duty conveyor belt rollers is meticulously engineered for durability and efficiency. They typically feature a sturdy steel or cast iron core that provides the necessary structural integrity under immense weight and pressure. The core is often coated with a corrosion-resistant material such as stainless steel or a protective layer of paint to prevent rust and extend the lifespan of the roller. Additionally, the bearings used within these rollers are of high quality, capable of enduring prolonged usage while minimizing friction and wear.

In terms of application, heavy-duty conveyor belt rollers are commonly found in industries where large quantities of goods need to be transported over long distances. For example, in mining operations, these rollers facilitate the movement of extracted materials from the excavation site to processing plants. Similarly, in warehouses and distribution centers, they play a crucial role in managing inventory by moving products efficiently along various stages of the supply chain.

The performance of heavy-duty conveyor belt rollers can significantly impact the overall productivity of a facility

The performance of heavy-duty conveyor belt rollers can significantly impact the overall productivity of a facility The performance of heavy-duty conveyor belt rollers can significantly impact the overall productivity of a facility

The performance of heavy-duty conveyor belt rollers can significantly impact the overall productivity of a facility

The performance of heavy-duty conveyor belt rollers can significantly impact the overall productivity of a facility

The performance of heavy-duty conveyor belt rollers can significantly impact the overall productivity of a facility heavy duty conveyor belt rollers. When these rollers function optimally, they ensure smooth transitions of goods, reducing bottlenecks and downtime. This seamless operation not only saves time but also cuts costs associated with manual labor and potential damage to goods due to handling errors.

However, like any machinery, proper maintenance is key to preserving the functionality of heavy-duty conveyor belt rollers. Regular inspections should be scheduled to identify any signs of wear or damage that could compromise their performance. Lubrication of the bearings is also critical to prevent premature failure and to maintain efficient operation.

In conclusion, heavy-duty conveyor belt rollers are indispensable elements in industrial settings where bulk material handling is a necessity. Their design emphasizes strength and resilience, making them suitable for supporting hefty loads over extensive periods. As technology advances, it is likely that further innovations will enhance the reliability and efficiency of these vital components, ensuring that industries remain competitive and adaptable to changing demands.

heavy duty conveyor belt rollers. When these rollers function optimally, they ensure smooth transitions of goods, reducing bottlenecks and downtime. This seamless operation not only saves time but also cuts costs associated with manual labor and potential damage to goods due to handling errors.

However, like any machinery, proper maintenance is key to preserving the functionality of heavy-duty conveyor belt rollers. Regular inspections should be scheduled to identify any signs of wear or damage that could compromise their performance. Lubrication of the bearings is also critical to prevent premature failure and to maintain efficient operation.

In conclusion, heavy-duty conveyor belt rollers are indispensable elements in industrial settings where bulk material handling is a necessity. Their design emphasizes strength and resilience, making them suitable for supporting hefty loads over extensive periods. As technology advances, it is likely that further innovations will enhance the reliability and efficiency of these vital components, ensuring that industries remain competitive and adaptable to changing demands.

The performance of heavy-duty conveyor belt rollers can significantly impact the overall productivity of a facility

The performance of heavy-duty conveyor belt rollers can significantly impact the overall productivity of a facility

The performance of heavy-duty conveyor belt rollers can significantly impact the overall productivity of a facility

The performance of heavy-duty conveyor belt rollers can significantly impact the overall productivity of a facility heavy duty conveyor belt rollers. When these rollers function optimally, they ensure smooth transitions of goods, reducing bottlenecks and downtime. This seamless operation not only saves time but also cuts costs associated with manual labor and potential damage to goods due to handling errors.

However, like any machinery, proper maintenance is key to preserving the functionality of heavy-duty conveyor belt rollers. Regular inspections should be scheduled to identify any signs of wear or damage that could compromise their performance. Lubrication of the bearings is also critical to prevent premature failure and to maintain efficient operation.

In conclusion, heavy-duty conveyor belt rollers are indispensable elements in industrial settings where bulk material handling is a necessity. Their design emphasizes strength and resilience, making them suitable for supporting hefty loads over extensive periods. As technology advances, it is likely that further innovations will enhance the reliability and efficiency of these vital components, ensuring that industries remain competitive and adaptable to changing demands.

heavy duty conveyor belt rollers. When these rollers function optimally, they ensure smooth transitions of goods, reducing bottlenecks and downtime. This seamless operation not only saves time but also cuts costs associated with manual labor and potential damage to goods due to handling errors.

However, like any machinery, proper maintenance is key to preserving the functionality of heavy-duty conveyor belt rollers. Regular inspections should be scheduled to identify any signs of wear or damage that could compromise their performance. Lubrication of the bearings is also critical to prevent premature failure and to maintain efficient operation.

In conclusion, heavy-duty conveyor belt rollers are indispensable elements in industrial settings where bulk material handling is a necessity. Their design emphasizes strength and resilience, making them suitable for supporting hefty loads over extensive periods. As technology advances, it is likely that further innovations will enhance the reliability and efficiency of these vital components, ensuring that industries remain competitive and adaptable to changing demands. Latest news

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025

OUR PRODUCTS