Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

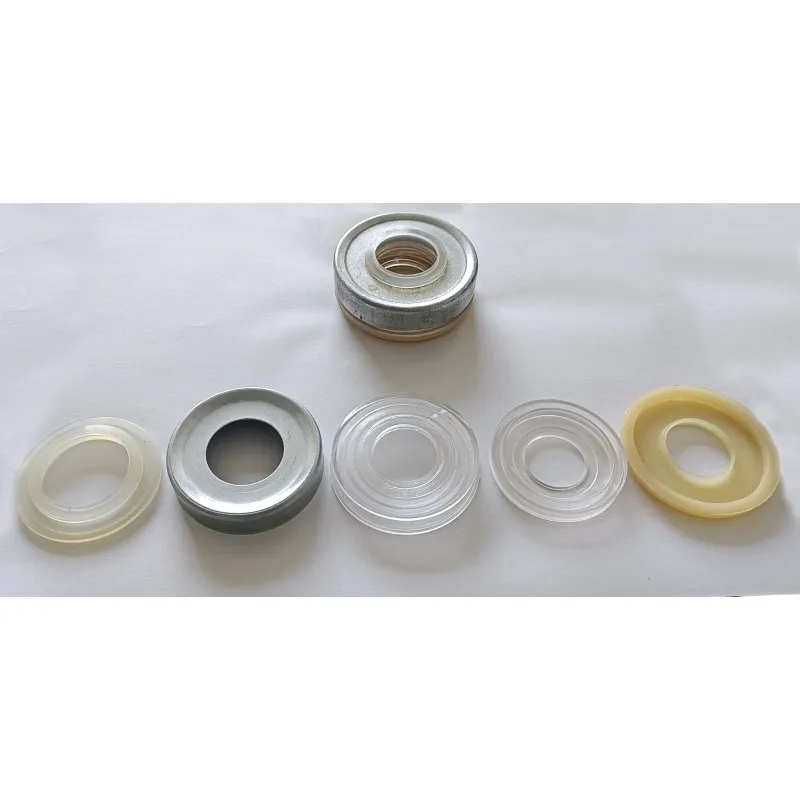

Zulu High-Quality Idler Bearing Housing: Steel, Sealed for Durability

The Crucial Role of idler bearing housing in Industrial Conveyance

In the vast landscape of industrial material handling, the efficiency and longevity of conveyor systems are paramount. At the heart of a reliable conveyor system lies the idler bearing housing, a critical component that ensures smooth rotation and structural integrity of conveyor rollers. These housings, often overlooked, play a pivotal role in minimizing friction, protecting bearings from harsh environments, and ultimately reducing operational costs. From heavy mining operations to intricate logistics hubs, the demand for robust and precisely engineered bearing housings continues to rise, driven by the relentless pursuit of higher throughput and lower maintenance requirements across various industries.

Industry trends indicate a significant shift towards more durable materials and advanced sealing technologies, especially for applications involving abrasive dust, moisture, and extreme temperatures. Manufacturers are increasingly focusing on solutions that offer extended service life and reduced total cost of ownership (TCO). This includes innovations in materials science for improved corrosion resistance and wear characteristics, alongside sophisticated sealing designs like labyrinth seals, which are essential for preventing contaminant ingress and lubricant egress. Such advancements directly contribute to the reliability and efficiency of entire conveyor systems, making them indispensable for modern industrial operations.

Manufacturing Excellence: The Process Behind Robust Idler Bearing Housing

The production of high-performance idler bearing housing units involves a meticulous multi-stage manufacturing process designed to meet stringent industry standards and application demands. Initially, raw materials, often high-grade `steel bearing housing` alloys or specialized composites, are selected based on the required mechanical properties, such as tensile strength, impact resistance, and corrosion immunity. For standard applications, pressed steel is common, while heavy-duty environments might require cast iron or even stainless steel. The choice of material directly influences the product's lifespan and performance under specific operating conditions, ensuring optimal durability.

The manufacturing process typically begins with either pressing (for steel housings), casting (for cast iron), or forging, depending on the design and material. This initial forming is followed by precision machining, often utilizing Computer Numerical Control (CNC) technology, to achieve tight tolerances for bearing fit, bore concentricity, and axial runout. This precision is critical for minimizing vibration, reducing noise, and extending bearing life. Post-machining, surfaces may undergo heat treatment for enhanced hardness or surface coatings for improved corrosion resistance. Every batch is subjected to rigorous quality control, including dimensional checks, material composition analysis (e.g., spectroscopy), and functional testing to ensure compliance with international standards such as ISO (International Organization for Standardization) for bearing fits and ANSI/ABMA (American National Standards Institute/American Bearing Manufacturers Association) for bearing performance. Our commitment to ISO 9001:2015 certified processes ensures consistent quality and reliability, guaranteeing a minimum operational lifespan of 5-7 years for our standard units under typical conditions, with specialized units designed for even longer service in critical applications like petrochemical and metallurgy.

Illustration of advanced machining for conveyor roller bearing housing components.

Technical Specifications and Performance Metrics

Understanding the technical parameters of a conveyor bearing housing is crucial for selection and optimal performance. Key specifications define its suitability for different industrial applications and environmental conditions. Our designs prioritize not only mechanical strength but also the integration of advanced sealing solutions to protect internal bearings. For instance, our AH Labyrinth Seal, specifically designed for these housings, provides superior protection against dust and moisture, a common challenge in mining and bulk material handling. This sealed bearing housing technology significantly extends the maintenance intervals and operational life of the entire roller assembly, delivering tangible benefits in terms of reduced downtime and maintenance costs. The table below outlines typical technical parameters.

| Parameter | Typical Range/Value | Impact on Performance |

|---|---|---|

| Material Type | Q235 Steel, HT200 Cast Iron, Stainless Steel 304/316 | Corrosion resistance, strength, cost |

| Bore Diameter (ID) | 62mm - 200mm (or customized) | Bearing compatibility, load capacity |

| Wall Thickness | 3mm - 10mm (depending on housing size) | Structural rigidity, impact resistance |

| Concentricity Tolerance | ISO P5/P6 Equivalent | Reduced vibration, extended bearing life |

| Sealing Type | Labyrinth Seal (e.g., AH Labyrinth Seal), Contact Seals | Protection against contaminants, lubricant retention |

| Operating Temperature Range | -30°C to +120°C (material dependent) | Suitability for various environments |

| Service Life (Typical) | >50,000 operational hours (with proper maintenance) | Cost-effectiveness, reduced downtime |

Our housings are engineered for optimal energy efficiency. By ensuring precise manufacturing tolerances and integrating superior sealing solutions, we minimize frictional losses within the idler assembly. This reduction in friction translates directly into lower power consumption for the conveyor system, contributing significantly to energy savings and reducing operational carbon footprint. Furthermore, the robust design of our idler bearing housing offers excellent resistance to corrosion, even in highly aggressive environments, due to specific material treatments and coatings. This corrosion resistance ensures prolonged operational life, particularly important in industries such as chemical processing or water treatment, where exposure to corrosive agents is common.

Applications and Technical Advantages

The versatility of our idler bearing housing units makes them indispensable across a wide range of heavy industrial applications. In the mining sector, where extreme dust, moisture, and heavy loads are common, our robust `steel bearing housing` designs with advanced `sealed bearing housing` capabilities ensure uninterrupted operation. Similarly, in power generation plants, our `conveyor roller bearing housing` solutions provide critical support for coal handling systems, operating reliably under high temperatures and continuous duty cycles. Petrochemical facilities and steel mills also benefit from the superior durability and corrosion resistance of our specialized housings, which are designed to withstand challenging chemical exposures and high mechanical stresses. The reliability of these components directly impacts the overall efficiency and safety of these large-scale operations.

A robust idler bearing housing in a demanding industrial setting.

Our technical advantages extend beyond mere material strength. We integrate state-of-the-art sealing systems, like our proprietary AH Labyrinth Seal, which significantly outperforms traditional seals in preventing contaminant ingress. This is crucial for environments with high particulate matter, such as cement production or grain handling. Furthermore, our housings are designed for ease of installation and maintenance, featuring precise fitments that reduce installation time and future servicing requirements. This thoughtful engineering not only enhances system uptime but also reduces labor costs for our clients, demonstrating a clear return on investment. Through rigorous in-house testing and third-party certifications (e.g., CEMA standards for conveyor components), we ensure our products consistently deliver superior performance and reliability.

Tailored Solutions and Client Success Stories

Recognizing that no two industrial applications are exactly alike, we offer comprehensive customization options for our `conveyor bearing housing` products. Whether it's unique bore sizes, specialized mounting configurations, or specific material requirements for extreme environments (e.g., highly corrosive acids or ultra-high temperatures), our engineering team collaborates closely with clients to develop bespoke `idler bearing housing` solutions. This includes design iterations, prototyping, and rigorous testing to ensure the customized solution meets precise performance criteria. Our agile manufacturing capabilities allow us to respond quickly to unique project demands, delivering high-quality, tailor-made components within competitive lead times. Our service history spanning over two decades in the industry attests to our capability in delivering solutions that not only meet but exceed client expectations.

A prime example of our tailored approach is a recent project for a large-scale iron ore mine in Western Australia. The client faced recurring issues with premature `conveyor roller bearing housing` failures due to extreme abrasive dust and moisture, leading to significant downtime. We engineered a custom `steel bearing housing` solution featuring an enhanced labyrinth seal design and a specialized corrosion-resistant coating. After implementation, the mine reported a 60% reduction in `idler bearing housing` failures within the first year, resulting in substantial savings on maintenance and increased operational uptime. This success story underscores our expertise in delivering high-value engineering solutions that address specific client challenges, reinforcing our commitment to long-term partnerships and operational excellence.

Manufacturer Comparison and Strategic Partnerships

When selecting a supplier for `idler bearing housing` units, discerning between manufacturers is crucial. While many offer standard products, our distinction lies in our unwavering commitment to precision engineering, material science expertise, and customer-centric service. Unlike some competitors who may compromise on material quality or manufacturing tolerances to reduce costs, we uphold stringent quality controls that adhere to international standards. Our investment in advanced CNC machining and automated production lines ensures consistent product quality and dimensional accuracy, critical factors for long-term performance. This contrasts sharply with suppliers relying on less precise methods, which can lead to premature wear and higher total cost of ownership for end-users. We utilize specific tests, such as dynamic load testing and accelerated life cycle testing, to validate the performance claims of our `conveyor bearing housing` products against industry benchmarks.

Our strategic partnerships with leading bearing manufacturers and raw material suppliers also provide a competitive edge. These collaborations enable us to access cutting-edge technologies and materials, ensuring that our `idler bearing housing` designs are always at the forefront of innovation. Furthermore, our global distribution network and dedicated technical support teams ensure timely delivery and responsive assistance, irrespective of geographical location. This holistic approach to product development, manufacturing, and customer support positions us as a reliable and authoritative choice for businesses seeking high-performance and durable `sealed bearing housing` solutions. We pride ourselves on transparent communication, from initial consultation to after-sales service, building trust and fostering enduring business relationships.

Frequently Asked Questions (FAQ)

Q1: What industries commonly use your `idler bearing housing`?

A1: Our `idler bearing housing` units are extensively used across diverse heavy industries including mining, power generation (coal handling), cement production, port logistics, metallurgy (steel mills), petrochemicals, agricultural bulk handling, and water treatment plants, where robust and reliable conveyor systems are essential.

Q2: What is the typical lead time for custom `conveyor roller bearing housing` orders?

A2: For custom `conveyor roller bearing housing` orders, the typical lead time ranges from 4 to 8 weeks, depending on the complexity of the design, material availability, and order volume. We maintain open communication throughout the production cycle to keep our clients informed of progress and delivery schedules.

Q3: Do your `sealed bearing housing` products come with a warranty?

A3: Yes, all our `sealed bearing housing` products are backed by a comprehensive 2-year warranty against manufacturing defects and material failures under normal operating conditions. Our commitment to quality ensures peace of mind for our customers. We also offer extended support and maintenance agreements.

Q4: How do your `idler bearing housing` designs contribute to energy saving?

A4: Our `idler bearing housing` designs minimize energy consumption through precision machining and superior sealing technologies. This reduces friction and optimizes roller rotation, leading to lower power demands for the conveyor system. In real-world applications, this translates to noticeable reductions in operational electricity costs over time, contributing to both economic and environmental sustainability.

References

- International Organization for Standardization (ISO) technical standards for bearing applications and quality management systems.

- American National Standards Institute (ANSI) and American Bearing Manufacturers Association (ABMA) standards for bearing components and practices.

- Conveyor Equipment Manufacturers Association (CEMA) standards for conveyor idler design and performance.

- Academic studies on tribology and lubrication in harsh industrial environments.

- Materials science journals focusing on advanced alloys and composite materials for high-wear applications.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025