Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

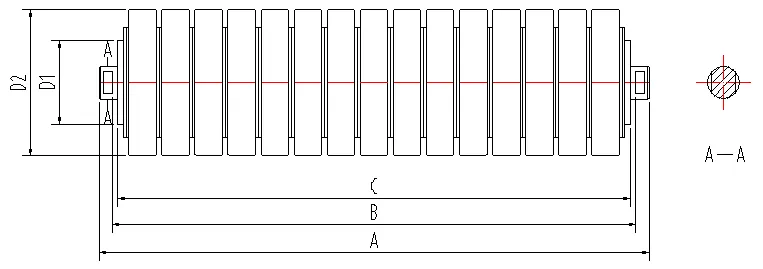

Zulu head pulley tail pulley

Understanding Head Pulleys and Tail Pulleys in Conveyor Systems

Conveyor systems are an essential component of modern industry, facilitating the efficient movement of materials across various processes. Among the critical components of these systems are head pulleys and tail pulleys, which play vital roles in the functionality and efficiency of conveyor belts. Understanding these elements can provide insights into how conveyor systems operate and the importance of maintenance, design, and functionality.

What are Head and Tail Pulleys?

Head Pulley The head pulley is located at the discharge end of a conveyor system. It is typically the drive pulley, meaning it is connected to a motor that powers the conveyor belt. The head pulley ensures that the belt maintains tension and moves in a continuous loop, allowing materials to be transported efficiently from one location to another. In many cases, the head pulley is slightly larger in diameter, which aids in better grip and traction for the belt, thereby enhancing the overall effectiveness of the system.

Tail Pulley In contrast, the tail pulley is located at the loading end of the conveyor belt. Its primary role is to provide support to the belt as it moves back to the head pulley after discharging its load. The tail pulley helps maintain the tension of the conveyor belt, preventing sagging and ensuring a smooth transition for materials being loaded onto the belt. This pulley does not typically drive the system but plays a crucial role in its overall stability.

Importance of Head and Tail Pulleys

Head and tail pulleys are vital for several reasons

head pulley tail pulley

1. Efficiency These pulleys enable the continuous operation of conveyor systems, ensuring that materials are transported efficiently without interruptions. A well-functioning head pulley drives the belt, while the tail pulley assists in maintaining tension.

2. Wear and Tear Over time, head and tail pulleys can experience wear and tear due to friction, environmental conditions, and the weight of the materials being transported. Monitoring their condition is essential for the longevity of the conveyor system. Regular inspections can identify issues such as misalignment, corrosion, or excessive wear, allowing for timely maintenance or replacement.

3. Safety Properly functioning head and tail pulleys contribute to the overall safety of the conveyor system. A malfunctioning head pulley can lead to belt slippage or a complete breakdown, posing risks to personnel and equipment. Ensuring that these pulleys are in good condition is essential for hazard prevention.

4. Design Considerations When designing a conveyor system, consideration of the head and tail pulleys is crucial. Engineers must carefully calculate the pulley diameters, material types, and tension specifications to ensure optimal performance. The right design can improve efficiency, reduce energy consumption, and extend the lifespan of the conveyor system.

Conclusion

In summary, head pulleys and tail pulleys are integral components of conveyor systems that facilitate the smooth and efficient movement of materials across various industrial processes. Their roles in driving and supporting the conveyor belt cannot be understated, and their proper maintenance is essential for ensuring safety and efficiency. With a thorough understanding of these components, industries can better appreciate the engineering that underpins their operations and the importance of regular maintenance to ensure longevity and reliability. Whether in manufacturing, mining, or logistics, recognizing the significance of head and tail pulleys will contribute to improved operational practices and enhanced productivity.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025