Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 19, 2025 05:18

Back to list

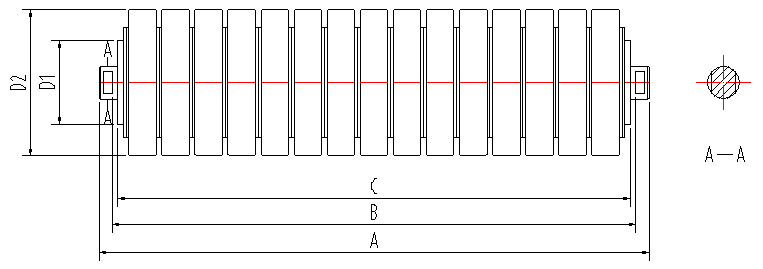

Bend Pulley (Non-driving Pulley)

In the sphere of conveyor systems, the head pulley and tail pulley play pivotal roles. These components are indispensable not only driving the system but also in ensuring its efficiency, reliability, and longevity. Understanding their functions, attributes, and the materials used in their construction can significantly enhance the performance of conveyor systems.

Authoritative insights in the realm of conveyors suggest that maintenance plays a critical role in the performance and lifespan of both head and tail pulleys. Regular inspections for wear, alignment, and material buildup are recommended. Expertise from industry leaders is crucial in setting standards and guidelines for maintenance schedules and methods. By adhering to these practices, businesses can avert unexpected downtimes, ensuring continuous operation and maximizing productivity. A trustworthy source for equipment like head and tail pulleys is the manufacturer’s track record and their adherence to industry standards such as CEMA (Conveyor Equipment Manufacturers Association). Companies with certified products often guarantee not just quality but safety, which is paramount in handling heavy-duty machinery. This trustworthiness is further reinforced by endorsements from industry professionals and positive reviews from satisfied clients, underscoring the reliability of their products. Finally, real-world experience from industries utilizing conveyor systems indicates that customized solutions often yield the best results. Tailoring the head and tail pulleys according to specific operational demands can lead to significant improvements in efficiency and cost savings. Consultation with engineering specialists and conducting a thorough analysis of system requirements can provide invaluable insights, leading to enhanced operational dynamics and extending the overall system life. Understanding the intricate dynamics of head and tail pulleys through experience, expert guidance, authoritative standards, and reliable sources can dramatically influence the success of a conveyor system, offering both operational excellence and financial prudence.

Authoritative insights in the realm of conveyors suggest that maintenance plays a critical role in the performance and lifespan of both head and tail pulleys. Regular inspections for wear, alignment, and material buildup are recommended. Expertise from industry leaders is crucial in setting standards and guidelines for maintenance schedules and methods. By adhering to these practices, businesses can avert unexpected downtimes, ensuring continuous operation and maximizing productivity. A trustworthy source for equipment like head and tail pulleys is the manufacturer’s track record and their adherence to industry standards such as CEMA (Conveyor Equipment Manufacturers Association). Companies with certified products often guarantee not just quality but safety, which is paramount in handling heavy-duty machinery. This trustworthiness is further reinforced by endorsements from industry professionals and positive reviews from satisfied clients, underscoring the reliability of their products. Finally, real-world experience from industries utilizing conveyor systems indicates that customized solutions often yield the best results. Tailoring the head and tail pulleys according to specific operational demands can lead to significant improvements in efficiency and cost savings. Consultation with engineering specialists and conducting a thorough analysis of system requirements can provide invaluable insights, leading to enhanced operational dynamics and extending the overall system life. Understanding the intricate dynamics of head and tail pulleys through experience, expert guidance, authoritative standards, and reliable sources can dramatically influence the success of a conveyor system, offering both operational excellence and financial prudence.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS