Feb . 20, 2025 10:43

Back to list

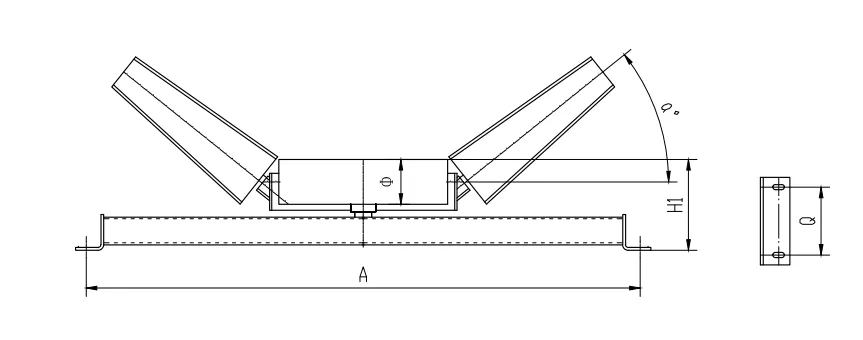

Bend Pulley (Non-driving Pulley)

The significance of head pulleys in industrial applications cannot be overstated. Head pulleys, often found in bulk material handling systems, play a crucial role in conveying systems, ensuring both efficiency and operational smoothness. Let's embark on an insightful journey into the world of head pulleys, exploring their construction, applications, and the critical attributes that every industry professional must consider.

Recent advancements in pulley technology further enhance their application. Innovations such as self-cleaning head pulleys reduce maintenance needs, offering solutions to material build-up issues. These are particularly beneficial in settings where continuous operation is critical, offering significant savings in downtime and maintenance labor. Choosing the right head pulley manufacturer is another critical decision-making factor. Partnering with reputable manufacturers ensures not only the integration of cutting-edge technology into pulley systems but also access to expert advice and support. These manufacturers have extensive field experience and provide valuable insights into product optimization, ensuring that the chosen head pulley aligns perfectly with the specific operational requirements. Furthermore, the installation of a head pulley significantly affects its performance. Proper alignment and tensioning are crucial; otherwise, even the most superior product might underperform or fail prematurely. Partnering with skilled installation teams ensures that pulleys are fitted to maximize performance, backed by the assurance of professional setup. In terms of maintenance, routine checks can extend the lifespan of head pulleys. Professionals recommend scheduled inspections to detect early signs of wear and tear, such as unusual noises, heat generation, or visible abrasions on the pulley surface. By addressing these issues proactively, industries can prevent costly downtime and extend the operational life of their investment. In conclusion, head pulleys are indispensable components in a range of industrial applications, offering a convergence of functionality, reliability, and safety. Their selection and maintenance require a blend of industry knowledge, technical expertise, and strategic foresight. With the right approach, businesses can not only enhance their operational efficiency but also secure a tangible competitive edge in their respective markets.

Recent advancements in pulley technology further enhance their application. Innovations such as self-cleaning head pulleys reduce maintenance needs, offering solutions to material build-up issues. These are particularly beneficial in settings where continuous operation is critical, offering significant savings in downtime and maintenance labor. Choosing the right head pulley manufacturer is another critical decision-making factor. Partnering with reputable manufacturers ensures not only the integration of cutting-edge technology into pulley systems but also access to expert advice and support. These manufacturers have extensive field experience and provide valuable insights into product optimization, ensuring that the chosen head pulley aligns perfectly with the specific operational requirements. Furthermore, the installation of a head pulley significantly affects its performance. Proper alignment and tensioning are crucial; otherwise, even the most superior product might underperform or fail prematurely. Partnering with skilled installation teams ensures that pulleys are fitted to maximize performance, backed by the assurance of professional setup. In terms of maintenance, routine checks can extend the lifespan of head pulleys. Professionals recommend scheduled inspections to detect early signs of wear and tear, such as unusual noises, heat generation, or visible abrasions on the pulley surface. By addressing these issues proactively, industries can prevent costly downtime and extend the operational life of their investment. In conclusion, head pulleys are indispensable components in a range of industrial applications, offering a convergence of functionality, reliability, and safety. Their selection and maintenance require a blend of industry knowledge, technical expertise, and strategic foresight. With the right approach, businesses can not only enhance their operational efficiency but also secure a tangible competitive edge in their respective markets.

Latest news

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025

OUR PRODUCTS